Bi-component polysulfide sealant and preparation method thereof

A polysulfide sealant, two-component technology, applied in chemical instruments and methods, non-polymer adhesive additives, adhesives, etc., can solve the problems of poor thermal degradation resistance and high density, and achieve thermal degradation resistance Excellent, good strength retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

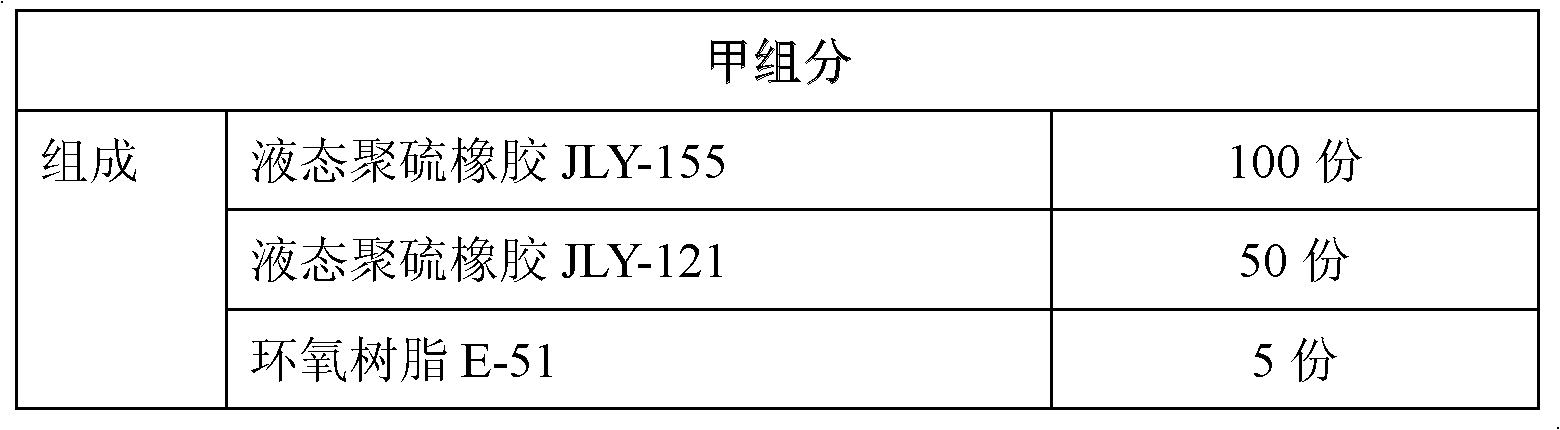

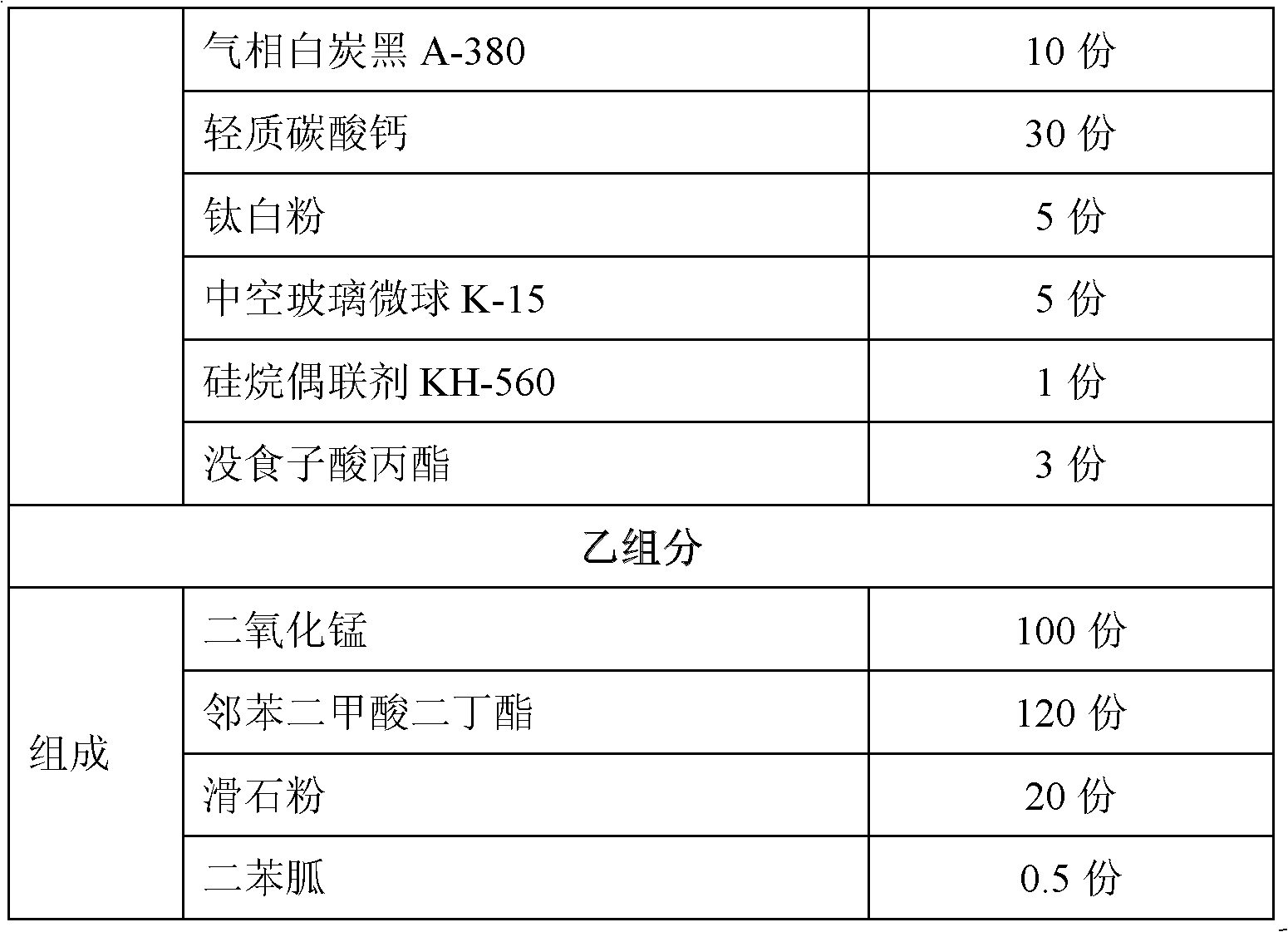

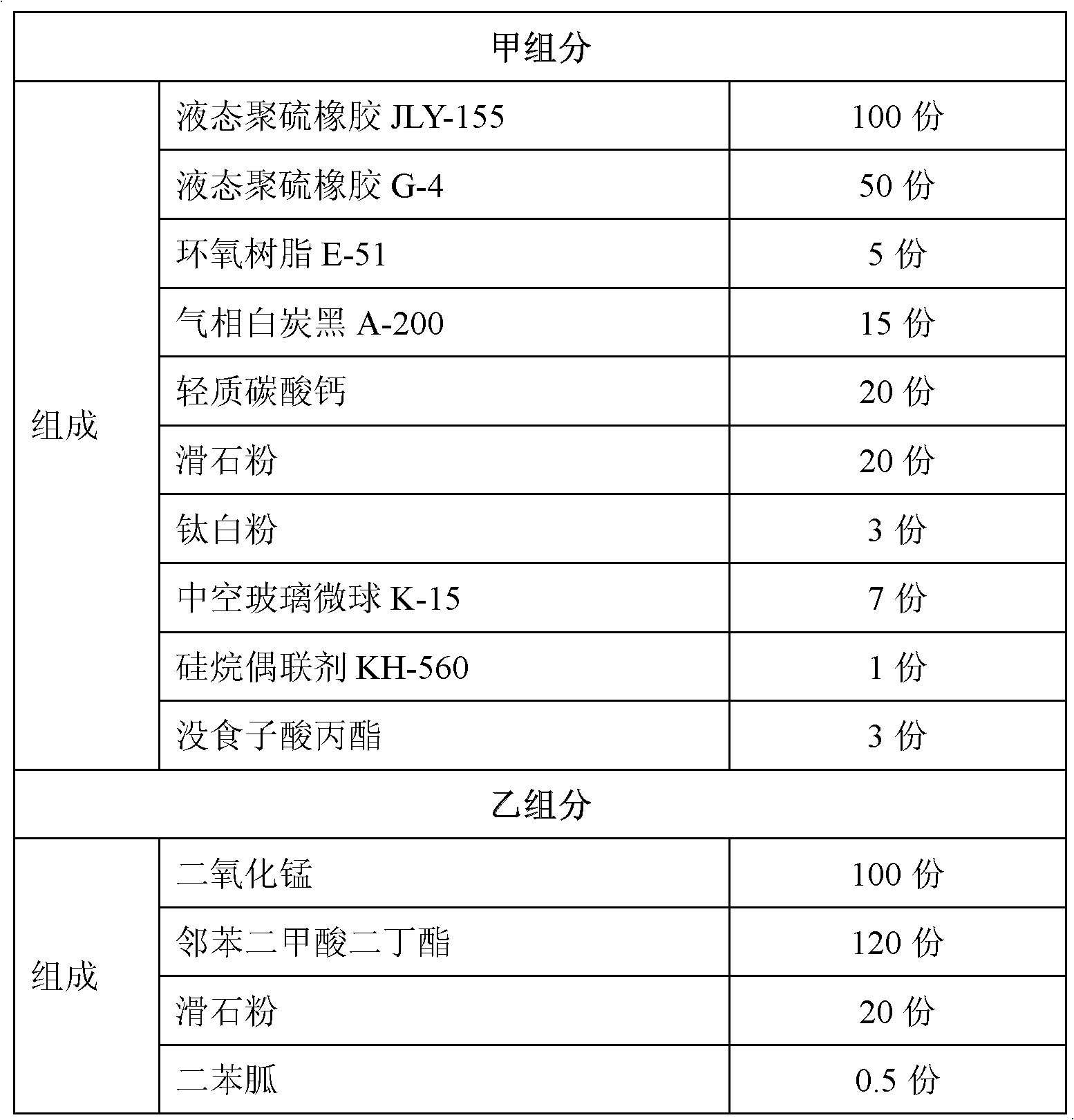

[0023] Specific embodiment one: The two-component polysulfide sealant of this embodiment is prepared from the following components in parts by weight:

[0024] Component A: 50-100 parts of high-viscosity liquid polysulfide rubber, 50 parts of low-viscosity liquid polysulfide rubber, 5-10 parts of epoxy resin, 5-15 parts of thixotropic agent, 20-60 parts of reinforcing filler, insulating glass 3-10 parts of microspheres, 5-10 parts of titanium dioxide, 0.5-1.5 parts of silane coupling agent, 2-6 parts of anti-aging agent; the anti-aging agent is propyl gallate;

[0025] Component B: 100 parts of manganese dioxide, 100-150 parts of plasticizer, 10-30 parts of talcum powder, 0.2-1.0 parts of diphenylguanidine;

[0026] During use, the weight proportion of component A and component B is: component A: component B=100: (10~15).

[0027] The raw materials used in the present invention are all commercially available products, wherein the hollow glass microspheres K1 and K15 are purch...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the high-viscosity liquid polysulfide rubber is one or both of liquid polysulfide rubber JLY-155 and liquid polysulfide rubber G-112. Than combination. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the low-viscosity liquid polysulfide rubber is one or both of liquid polysulfide rubber JLY-121 and liquid polysulfide rubber G-4 can be combined in any ratio. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com