Bonding type antiskid road and bridge panel made of glass fiber reinforced plastics

A fiberglass and sliding road bridge technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of unreasonable connection settings and poor wear resistance, and achieve the effects of reasonable design, good wear resistance and excellent anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

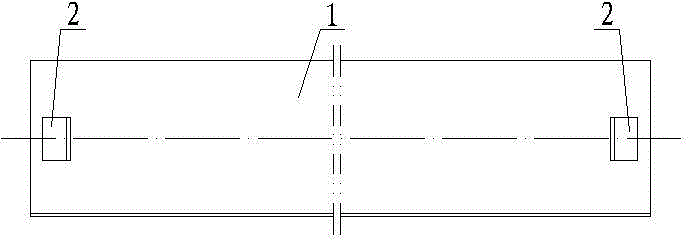

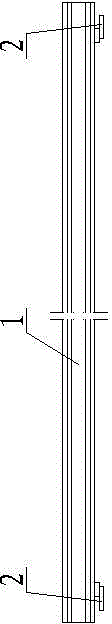

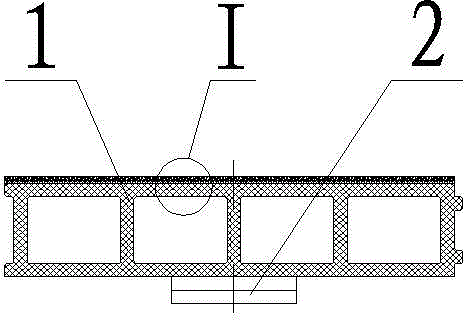

[0017] as attached figure 1 , 2 , 3, and 4, the panel main body 1 is a frame structure with grid-type reinforcing ribs inside, and lap joints along the length direction are provided on both sides, and the mutual insertion between the lap joints A plurality of panel main bodies 1 can be spliced into a whole; the connecting block 2 is set on the back of the panel main body 1 as the bridge surface, and is bonded with the panel main body 1, thereby forming the connecting block 2 and the panel main body 1 The card slot between the back, the panel main body 1 is connected with the external support member through the card slot; the anti-slip coating is composed of resin adhesive 4 and wear-resistant particles 5; the adhesive layer 3 is sprayed on the road and bridge surface of the panel main body 1 The wear-resistant particles 5 in the anti-slip coating are evenly distributed on the adhesive layer 3, and the wear-resistant particles 5 are bonded to the adhesive layer 3 by spraying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com