Cationic dyeable polyester composition as well as preparation method and application thereof

A composition, cationic technology, applied in the direction of one-component copolyester rayon, etc., can solve the problems of affecting the dyeing properties of modified polyester, low molecular weight of polyester, poor polyester reactivity, etc., and achieve low carboxyl group content. , Good hydrolysis resistance, easy dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

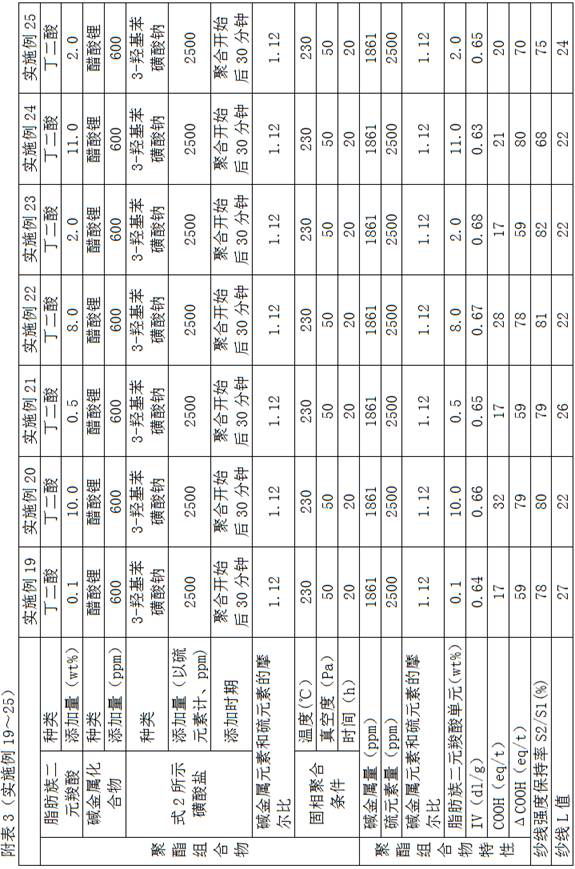

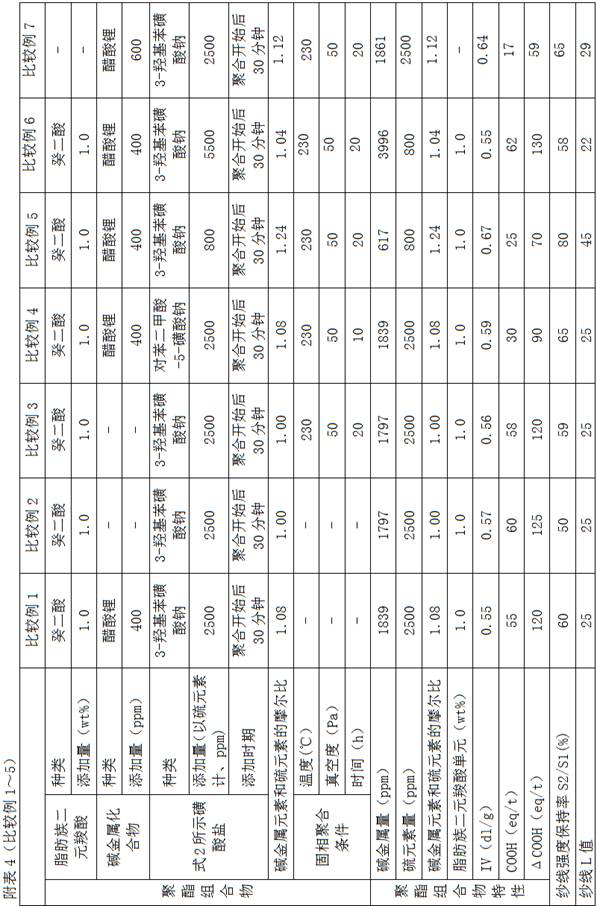

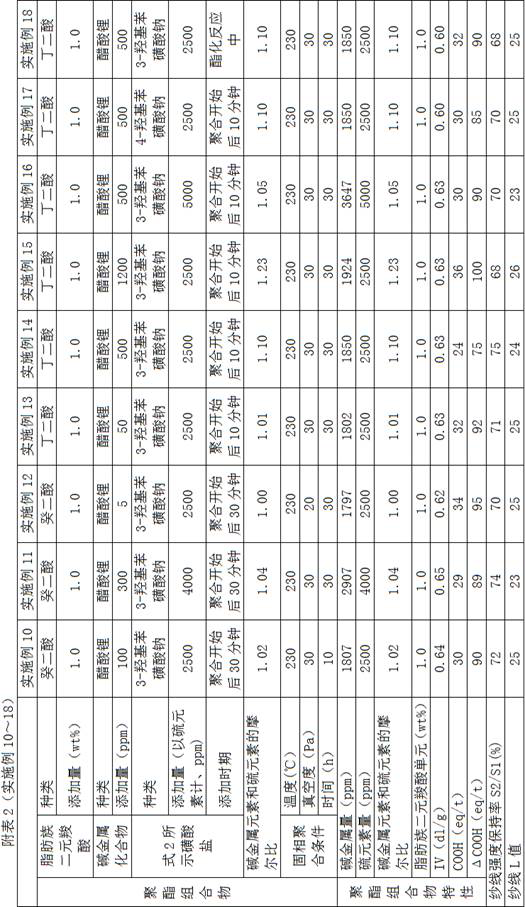

Examples

Embodiment 1

The terephthalic acid (PTA) and ethylene glycol (EG) were mixed uniformly and put into the reaction kettle, and the esterification reaction was carried out at 240°C. After the esterification reaction, the reaction product was transferred into a polycondensation kettle, and sebacic acid, antimony trioxide as a catalyst, trimethyl phosphate and lithium acetate as heat stabilizers were added before the polymerization reaction, and the polycondensation reaction was carried out at 290°C. The ethylene glycol solution of the sulfonate shown in formula 2 is added 30 minutes after the start of the polymerization reaction, and after the polymer reaches the required viscosity, it is spit out and diced to obtain the required polyester composition.

[0057]After the polyester product obtained by polycondensation is pre-crystallized, the reaction temperature is 230 ° C, the reaction pressure is 50 Pa, and the reaction time is 30 hours. The viscosity IV was 0.65 dl / g.

[0058] The polyester ...

Embodiment 2

The terephthalic acid (PTA) and ethylene glycol (EG) were mixed uniformly and put into the reaction kettle, and the esterification reaction was carried out at 240°C. After the esterification reaction, the reaction product was transferred into a polycondensation kettle, and sebacic acid, antimony trioxide as a catalyst, trimethyl phosphate and lithium acetate as heat stabilizers were added before the polymerization reaction, and the polycondensation reaction was carried out at 290°C. The ethylene glycol solution of the sulfonate shown in formula 2 is added 30 minutes after the start of the polymerization reaction, and after the polymer reaches the required viscosity, it is spit out and diced to obtain the required polyester composition.

[0060] After the polyester product obtained by polycondensation is pre-crystallized, the reaction temperature is 230 ° C, the reaction pressure is 50 Pa, and the reaction time is 30 hours. The viscosity IV was 0.65 dl / g.

[0061] The polyester...

Embodiment 3

The terephthalic acid (PTA) and ethylene glycol (EG) were mixed uniformly and put into the reaction kettle, and the esterification reaction was carried out at 240°C. After the esterification reaction, the reaction product was transferred into a polycondensation kettle, and sebacic acid, antimony trioxide as a catalyst, trimethyl phosphate and lithium acetate as heat stabilizers were added before the polymerization reaction, and the polycondensation reaction was carried out at 290°C. The ethylene glycol solution of the sulfonate shown in formula 2 is added 30 minutes after the start of the polymerization reaction, and after the polymer reaches the required viscosity, it is spit out and diced to obtain the required polyester composition.

[0063] After the polyester product obtained by polycondensation is subjected to pre-crystallization treatment, solid-phase polymerization is carried out under the conditions that the reaction temperature is 230 ° C, the reaction pressure is 50 P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com