Preparation method of black dyestuff for dyeing aluminum alloy and dyeing method of aluminum alloy

A technology of black dye and dyeing method, which is applied in the preparation of black dye for aluminum alloy dyeing and in the field of aluminum alloy dyeing, and can solve the problems such as dyeing difficult aluminum alloys into black

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

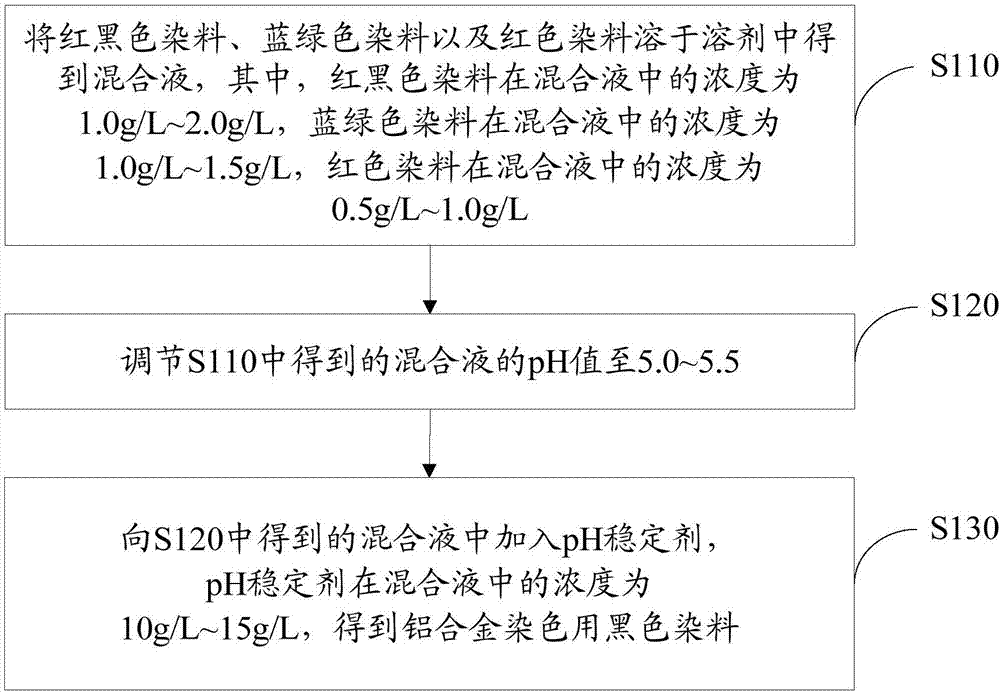

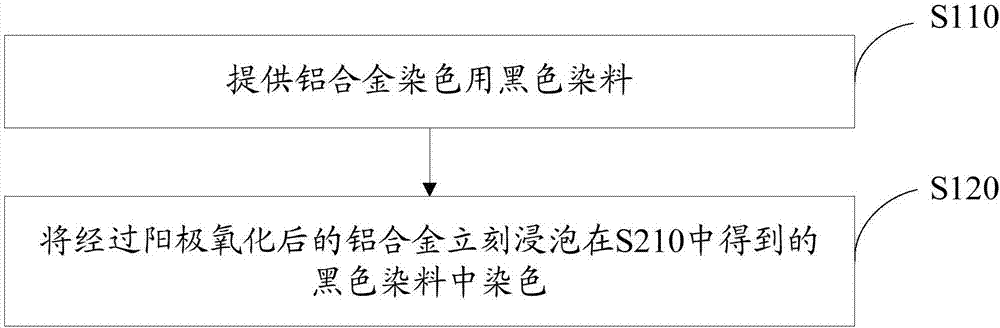

[0024] See figure 1 A method for preparing a black dye for dyeing aluminum alloy according to an embodiment includes the following steps S110 to S130.

[0025] S110. Dissolve red and black dyes, cyan dyes, and red dyes in a solvent to obtain a mixed solution, wherein the concentration of the red and black dyes in the mixed solution is 1.0 g / L~2.0 g / L, and the blue and green dyes are in the mixed solution The concentration of the red dye is 1.0g / L~1.5g / L, and the concentration of the red dye in the mixed solution is 0.5g / L~1.0g / L.

[0026] According to the total volume of black dyes for aluminum alloy dyeing to be configured, red-black dyes, blue-green dyes and red dyes can be added to obtain a mixed solution. Specifically, the solvent of the black dye for dyeing aluminum alloy may be water.

[0027] In this embodiment, red and black dyes, cyan dyes, and red dyes are dissolved in water to obtain a mixed solution, wherein the concentration of the red and black dyes in the mixed soluti...

Embodiment 1

[0052] Preparation of black dye for dyeing aluminum alloy

[0053] Dissolve Okuno Dye 402, Okuno Dye 411, and Okuno Dye 102 in water to obtain a mixed solution, wherein the addition amount of Okuno Dye 402 is 1.5g / L, the addition amount of Okuno Dye 411 is 1.25g / L, and Okuno Dye 102 is added The amount is 0.75g / L. Add NaOH to adjust the pH of the mixed solution to 5.25. And 12.5g / L of ammonium chloride was added to the mixed solution, and the black dye for aluminum alloy dyeing was obtained after mixing.

Embodiment 2

[0055] Preparation of black dye for dyeing aluminum alloy

[0056] Dissolve Okuno Dye 402, Okuno Dye 411, and Okuno Dye 102 in water to obtain a mixed solution. The addition amount of Okuno Dye 402 is 1.0g / L, the addition amount of Okuno Dye 411 is 1.0g / L, and the addition amount of Okuno Dye 102 is 1.0g / L. Add NaOH to adjust the pH of the mixed solution to 5.0. 10g / L of sodium acetate was added to the mixed solution to obtain a black dye for dyeing aluminum alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com