Dyeing and finishing process of linen type cloth

A dyeing and finishing technology, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of high hand feeling, elasticity and softness, and achieve the effect of ensuring stability and uniformity, and reducing color spots and spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

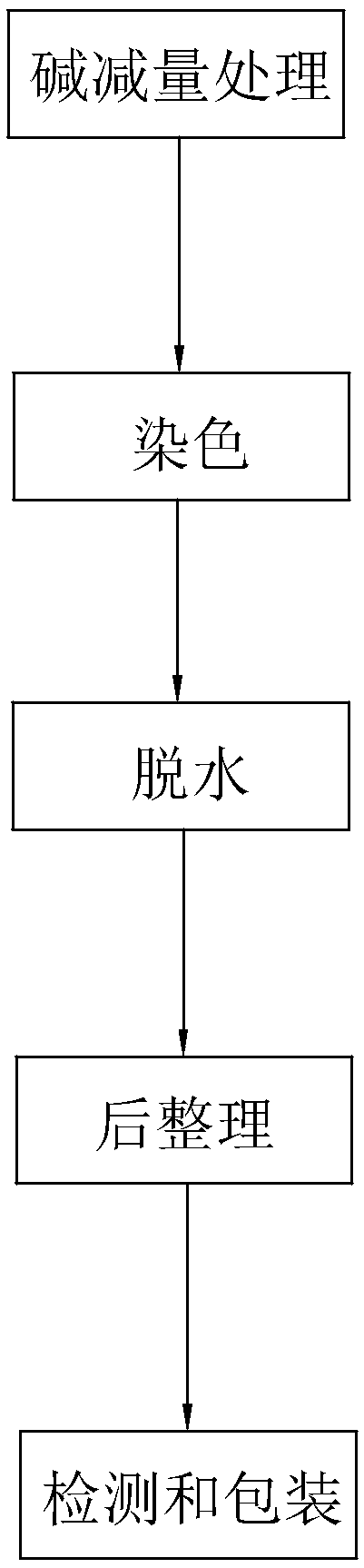

[0037] Embodiment 1: a kind of dyeing and finishing process of imitation linen, as figure 1 shown, including the following steps:

[0038] Step a, alkali weight reduction treatment: prepare the gray cloth (the cationic dyeable polyester yarn and ordinary polyester yarn are twisted and interwoven), and put it into the normal pressure J-type weight reduction machine. The alkali weight reduction conditions are as follows: the concentration of sodium hydroxide : 2-10g / L;

[0039] Accelerator 1227: 10 x 10 5 mol / L;

[0040] Surfactant R-201: 0.3g / L;

[0041] Anti-coagulant DN: 0.6g / L;

[0042] According to the bath ratio of 1:10, heat up to 100°C at 1°C / L, keep it warm for 30 minutes, fully carry out alkali reduction treatment, wash 2-3 times with water, and dry at 80°C;

[0043] Step b. Dyeing: put the gray cloth obtained in step a into the dyeing vat, add glacial acetic acid to adjust the pH to keep it at about 5-7, add dye and leveling agent 2B, heat up to 80°C at 1°C / min, ...

Embodiment 2

[0047] Embodiment 2: A dyeing and finishing process of imitating linen, the difference from Example 1 is that in step a, the accelerator added is a concentration of 10 × 10 5 mol / L accelerator 1631, the added surfactant is surfactant R-201 with a concentration of 0.3g / L.

Embodiment 3

[0048] Embodiment 3: a dyeing and finishing process of imitating linen, the difference from embodiment 1 is that in step a, the accelerator added is a concentration of 10 × 10 5mol / L accelerator 1631, the added surfactant is the surfactant AES with a concentration of 0.3g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com