Inner fiber reinforced wood-plastic product

A technology for wood-plastic products and fiber-reinforced materials, which can be applied to sheets/boards, floors, building elements, etc. Strength enhancement, saving fiber reinforced materials, and good strength retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

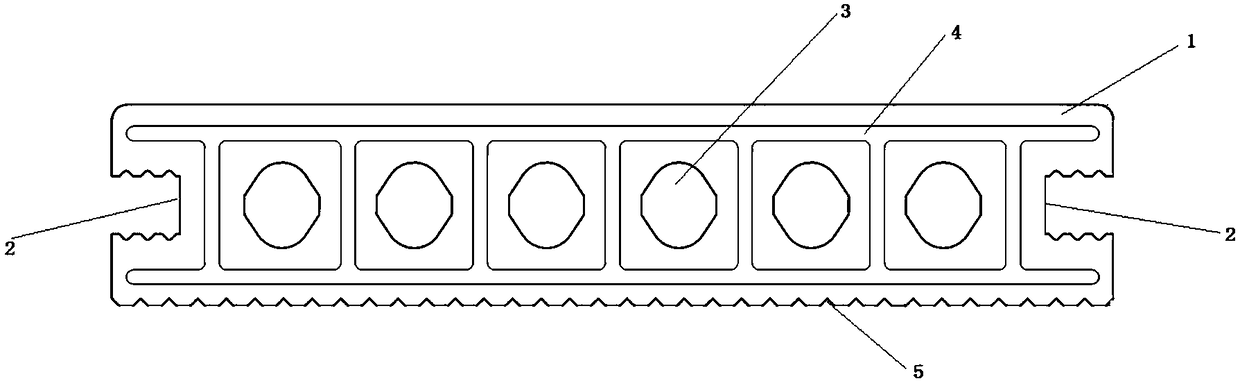

[0029] An embodiment of the fiber-reinforced wood-plastic product described in the present invention, the longitudinal section structure diagram of the fiber-reinforced wood-plastic product described in this embodiment is as attached figure 1 Shown:

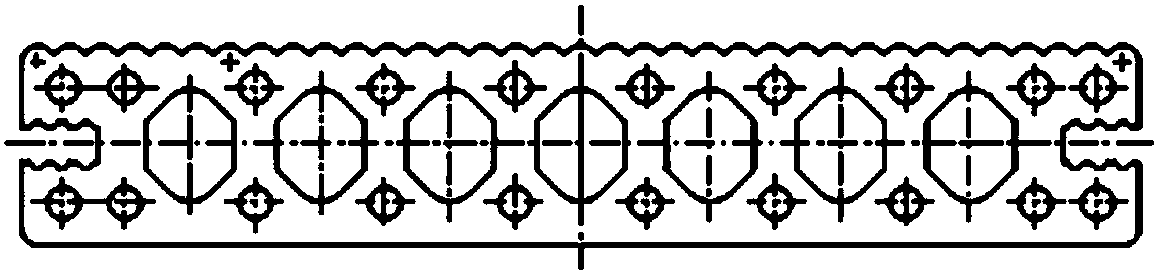

[0030] It includes the body 1 and the locking grooves 2 arranged on the left and right sides of the body 1. The body 1 is provided with a plurality of diamond-shaped through holes 3 that pass through the front and rear ends of the body. The diagonal length of the rhombus is 10mm-12mm. The through holes 3 and Between the surface of the main body 1 is provided a fiber reinforced material 4 that is close to the surface of the main body 1 and surrounds the through hole 3. The through hole 3 can be filled with fillers, which can be new materials or secondary materials; wood-plastic products are reinforced in fibers In the longitudinal section of , the fiber reinforced material 4 is connected by a plurality of "I" shapes, the thickness...

Embodiment 2

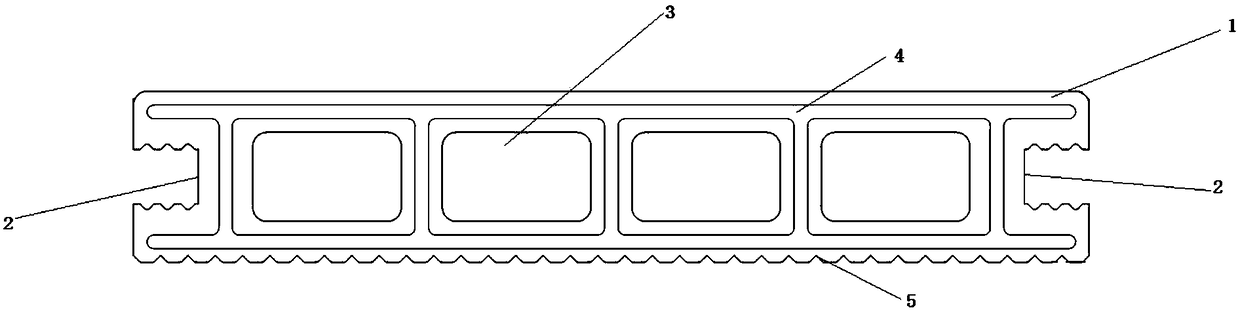

[0032] An embodiment of the fiber-reinforced wood-plastic product described in the present invention, the longitudinal section structure diagram of the fiber-reinforced wood-plastic product described in this embodiment is as attached figure 2 Shown:

[0033] Including the main body 1 and the locking grooves 2 arranged on the left and right sides of the main body 1, the main body 1 is provided with a plurality of rounded rectangular through holes 3 passing through the front and rear ends of the main body, and the diagonal length of the rounded rectangle is 20mm-22mm. Between the through hole 3 and the surface layer of the main body 1, there is a fiber reinforced material 4 close to the surface layer of the main body 1 and surrounding the through hole 3. The through hole 3 can be filled with fillers, which can be new materials or secondary materials; In the longitudinal section of the internally reinforced wood-plastic product, the fiber reinforced material 4 is connected by mu...

Embodiment 3

[0035] This example studies and analyzes the mechanical properties of the fiber-reinforced wood-plastic products of the present invention. The body of the fiber-reinforced wood-plastic products described in Examples 1-2 of the present invention consists of the following raw materials in parts by weight: 100 parts of surface layer polymer Resin, 30-70 parts of wood powder, 4-8 parts of surface stabilizer, 20-40 parts of calcium carbonate, 1.5-2.5 parts of foaming agent, 5-8 parts of foam regulator, 3-8 parts plasticizing stabilizer, 1-2 parts of antioxidant, 1-2 parts of ultraviolet absorber; the fiber reinforced material is composed of the following raw materials in parts by weight: 20-50 parts of core polymer resin, 20 parts of fiber ~60 parts, 4~8 parts of plasticizer, 1~3 parts of lubricant, 0.1~1 part of antioxidant, 0.1~1 part of core layer stabilizer, 1~3 parts of interface modifier. The performances of the fiber-reinforced wood-plastic products of the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com