Thermoplastic halogen-free few-smoke flame-proof cable sheath material and machining process

A cable sheath material and low-smoke flame-retardant technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of restricting the development of halogen-free low-smoke flame-retardant materials and greatly affecting the mechanical properties of materials, and achieve superior processing performance , Improve compatibility and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

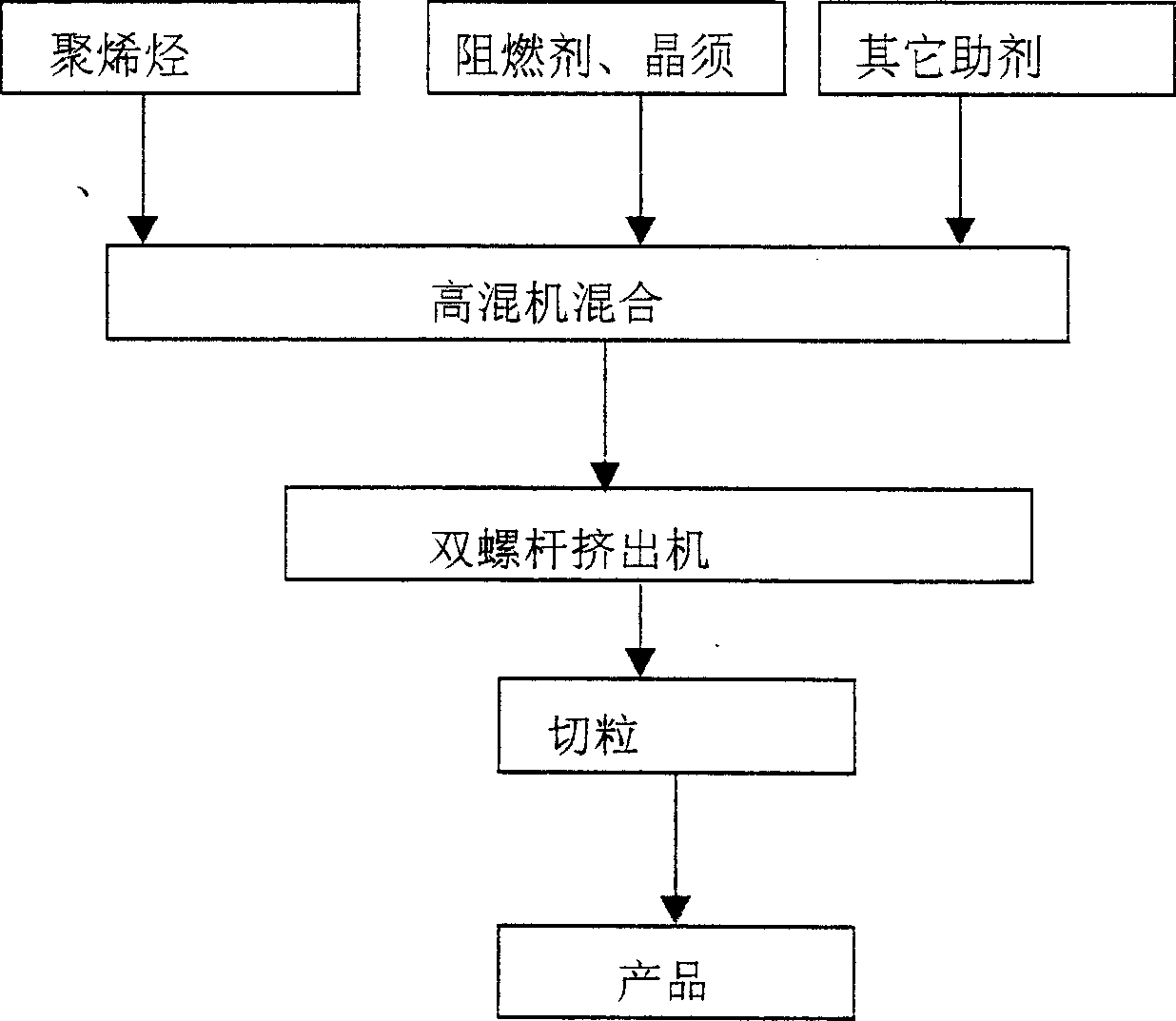

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Formulation Design

[0031] A: 100 grams of polyolefin resin (EVA);

[0032] B: 90 grams of aluminum hydroxide, 30 grams of magnesium salt whiskers, and the aspect ratio of the whisker material is 80;

[0033] C: 2 grams of silane 172 coupling agent, 3 grams of zinc stearate;

[0034] D: 2 grams of carbon black, 1 gram of paraffin.

[0035] Put A, B, C, and D into a high-speed mixer and stir evenly. The temperature is 100-120°C, the speed is 100-200rpm, and the mixture is complete.

[0036] Step 2: Processing

[0037] Control the temperature of the heating section of the twin-screw extruder at 140°C, add the mixed material in step 1, complete one-time processing, and pelletize after extrusion and air-cooling or water-cooling.

[0038] Step 3: Test Results

[0039] The pellets are extruded into tablets, and tested according to national standards or IEC and other standard test methods to achieve the following relevant technical performance indicators:

[004...

Embodiment 2

[0048] Step 1: Formulation Design

[0049] A: Polyolefin resin (EVA) 80 grams, (PC) 20 grams;

[0050] B: 80 grams of aluminum hydroxide, 40 grams of magnesium salt whiskers, and the aspect ratio of the whisker material is 70;

[0051] C: 2 grams of silane 171 coupling agent;

[0052] D: 2 grams of carbon black, 1 gram of paraffin.

[0053] Put A, B, C, and D into a high-speed mixer and stir evenly. The temperature is 100-120°C, the speed is 100-200rpm, and the mixture is complete.

[0054] Step 2: Processing

[0055] Control the temperature of the heating section of the twin-screw extruder at 150°C, add the mixed material in step 1, complete one-time processing, and pelletize after extrusion and air-cooling or water-cooling.

[0056] Step 3: Test Results

[0057] The pellets are extruded into tablets, and tested according to national standards or IEC and other standard test methods to achieve the following relevant technical performance indicators:

[0058] Tensile stre...

Embodiment 3

[0066] Step 1: Formulation Design

[0067] A: Polyolefin resin (EVA) 50 grams, (PC) 50 grams;

[0068] B: 70 grams of magnesium hydroxide, 40 grams of magnesium salt whiskers, and the aspect ratio of the whisker material is 30;

[0069] C: 2 grams of silane 55H coupling agent, 1 gram of titanate;

[0070] D: 3 grams of white carbon black, 2 grams of paraffin.

[0071] Put A, B, C, and D into a high-speed mixer and stir evenly. The temperature is 100-120°C, the speed is 100-200rpm, and the mixture is complete.

[0072] Step 2: Processing

[0073] Control the temperature of the heating section of the twin-screw extruder at 150°C, add the mixed material in step 1, complete one-time processing, and pelletize after extrusion and air-cooling or water-cooling.

[0074] Step 3: Test Results

[0075] The pellets are extruded into tablets, and tested according to national standards or IEC and other standard test methods to achieve the following relevant technical performance indica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com