High temperature resistance self-adhesion 3D (Three Dimensional) multi-color waterproof roll and preparation method thereof

A waterproof roll material and high temperature resistant technology, applied in chemical instruments and methods, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of inability to apply facade waterproof construction, low bonding and peeling strength, Self-adhesive adhesive layer has poor heat resistance and other problems, so as to achieve the effect of bright colors, rich patterns and shapes, and enhanced decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

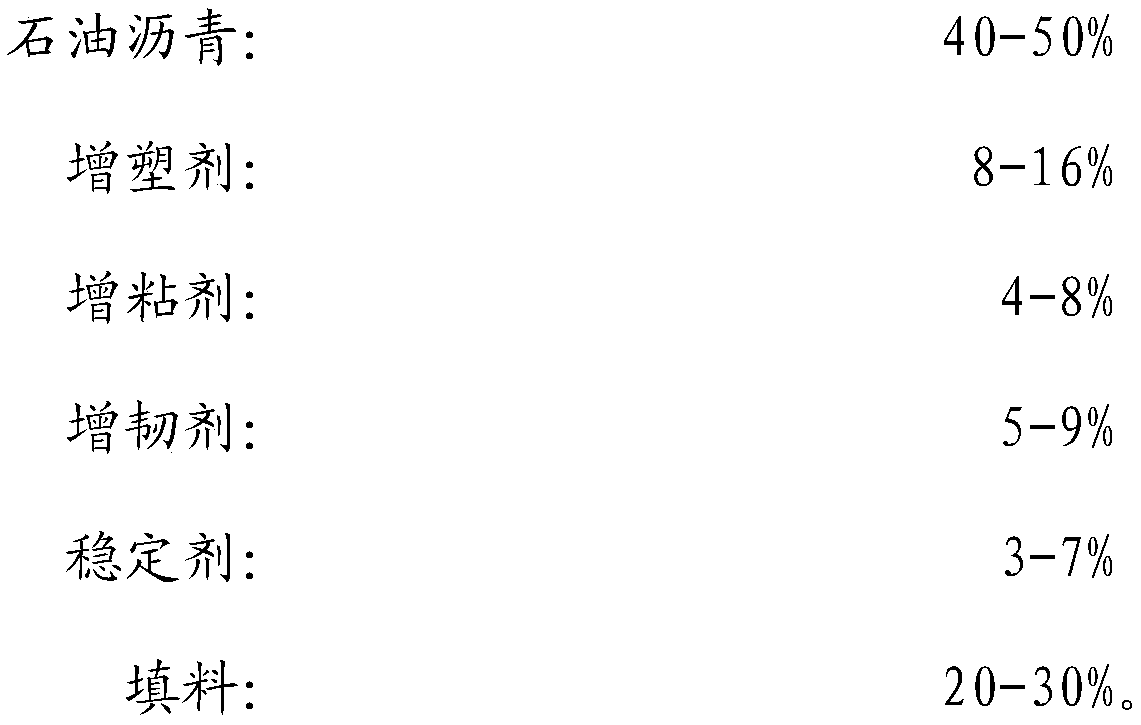

Method used

Image

Examples

Embodiment 1

[0024] Add 90# petroleum asphalt with a weight share of 45% and naphthenic oil with a weight share of 12% into the mixing tank, stir and raise the temperature to 130°C-140°C, keep it for 10 minutes, then heat up to 130-150°C at a constant speed Add petroleum resin with a weight ratio of 6%, keep the temperature at 130-150°C, stir for 60 minutes, then raise the temperature to 190°C, add SBS with a weight ratio of 7%, stir for 90 minutes and grind until the fineness reaches 80μm, and continue to maintain the temperature Control the temperature at 185°C to 195°C, add 5% hydroxyethyl cellulose by weight, stir at a constant speed for 60 minutes until it is completely dissolved, finally add 15% silicon aluminum carbon black and 10% silica powder by weight, and stir well After 60 minutes, the temperature drops to 160-170°C and the material is discharged for later use.

[0025] Dip the high-quality filament polyester felt into the high-temperature-resistant self-adhesive adhesive prep...

Embodiment 2

[0030] Add 100# petroleum asphalt with 42% weight share, 10% naphthenic oil and 5% aromatic oil into the mixing tank, stir and raise the temperature to 130°C-140°C, keep it for 10 minutes, and then heat up to 130°C ~150°C, add 4% terpene resin and 4% petroleum resin at a constant speed, keep the temperature at 130-150°C, stir for 60 minutes, then raise the temperature to 190°C, add 7% SBR by weight, and stir for 90 minutes and grind to make the fineness reach 80 μm, continue to keep the temperature controlled at 185°C to 195°C, add 3% sulfur by weight, stir at a constant speed for 60 minutes until it is completely dissolved, and finally add 5% talcum powder, 5% Silica-alumina carbon black, 3% heavy calcium carbonate, 4% calcium hydroxide, 2% light calcium, 6% silica microstone powder, after fully stirring for 60 minutes, the temperature drops to 160-170°C, and the material is discharged for later use.

[0031] On both sides of the polymer core material with a thickness of 1.2m...

Embodiment 3

[0036]Add 100# petroleum asphalt with a weight ratio of 40%, engine oil with a weight ratio of 8%, and aromatic hydrocarbon oil with a weight ratio of 5% into the mixing tank, stir and raise the temperature to 130°C-140°C, keep it for 10 minutes, and then heat up to 130-150°C Add 2% terpene resin, 2% petroleum resin, and 2% tackifying resin at a constant speed at ℃, keep the temperature at 130-150°C, stir for 60 minutes, then heat up to 190°C and add 5% SBR, 4 % SBS, stirred for 90 minutes and ground to make the fineness reach 80 μm, and continued to keep the temperature controlled at 185 ° C ~ 195 ° C, added 3% sulfur and 2% hydroxyethyl cellulose, and stirred at a constant speed for 60 minutes to reach its Dissolve completely, and finally add 5% talcum powder, 4% silica-alumina carbon black, 5% heavy calcium carbonate, 3% calcium hydroxide, 2% light calcium, 8% silica microstone powder by weight, and stir for 60 minutes , the temperature dropped to 160 ~ 170 ℃ discharge, sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com