A kind of preparation method of TIC reinforced ultra-fine grain β titanium niobium matrix composite material

A composite material and ultra-fine grain technology, applied in the field of metal matrix composite materials, can solve the problems of uneven distribution of TiC, complicated process, high density, etc., and achieve the effect of uniform distribution of reinforcement, easy promotion, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

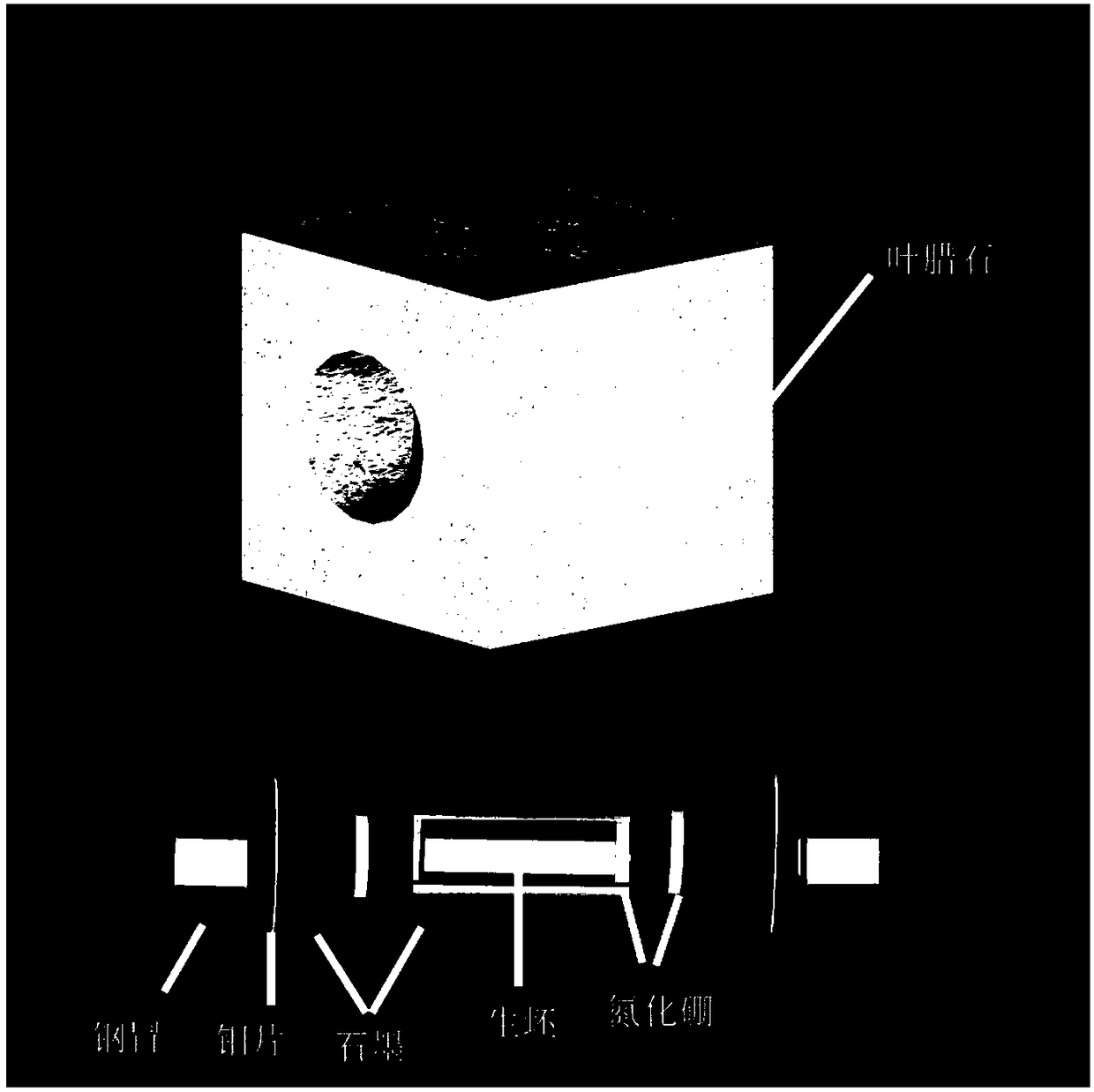

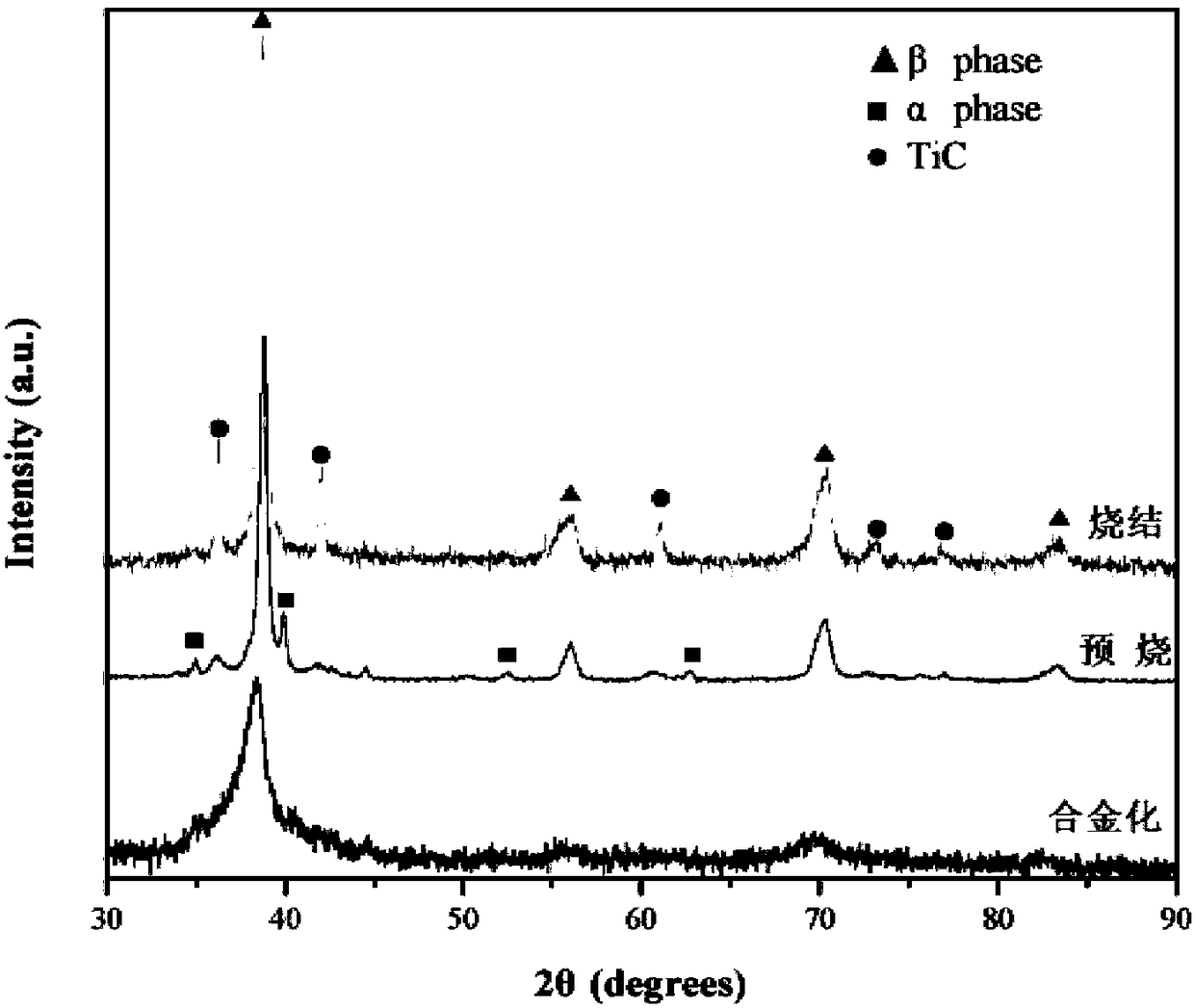

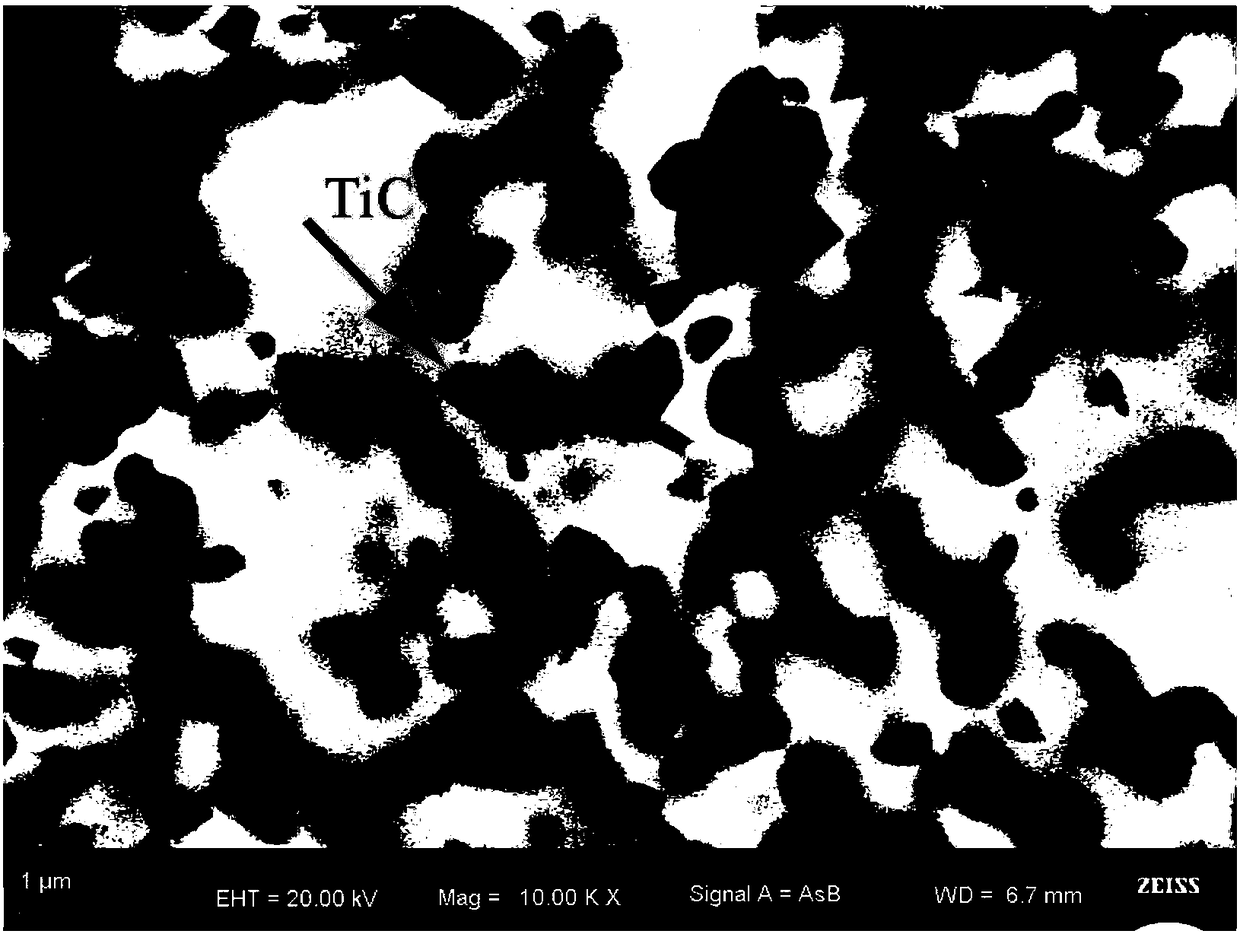

Method used

Image

Examples

Embodiment 1

[0046] Raw materials: Ti powder and Nb powder are both 50μm irregular powders with a purity of more than 99.9%, CH 3 (CH 2 ) 16 COOH is analytically pure.

[0047] Proportion weighing: Ti powder: Nb powder is 60:40 by mass ratio, CH 3 (CH 2 ) 16 The amount of COOH added is 2wt% of the sum of the mass of Ti powder and Nb powder.

[0048] Alloying by high-energy ball milling: put the weighed raw materials in a 250ml stainless steel vacuum ball mill tank, use stainless steel balls with a diameter of 15mm for the grinding balls, the weight of the balls is 300g, the ball-to-material ratio is 15:1, and vacuum the ball mill tank. Put it in a planetary ball mill (QM-3SP2) and ball mill it at a speed of 240r / min for 12 hours to obtain a fully alloyed powder. Pre-firing: Put the alloy powder obtained by ball milling into a porcelain crucible, place it in a high-vacuum vertical sintering furnace (ZM-30-16), and evacuate to a vacuum degree of 5×10 - 2 Pa, at a heating rate of 5 °C...

Embodiment 2

[0053] Raw materials: Ti powder and Nb powder are both 60μm irregular powders with a purity of more than 99.9%, CH 3 (CH 2 ) 16 COOH is analytically pure.

[0054] Proportion weighing: Ti powder: Nb powder is 67:33 by mass ratio, CH 3 (CH 2 ) 16 The amount of COOH added is 2.5wt% of the sum of the mass of Ti powder and Nb powder.

[0055] Alloying by high-energy ball milling: put the weighed raw materials in a 250ml stainless steel vacuum ball mill tank, use stainless steel balls with a diameter of 10mm for the grinding balls, weigh 300g, and have a ball-to-material ratio of 12:1. Put it in a planetary ball mill (QM-3SP2) and ball mill it at a speed of 220r / min for 10 hours to obtain a fully alloyed powder.

[0056] Pre-firing: Put the alloy powder obtained by ball milling into a porcelain crucible, place it in a high-vacuum vertical sintering furnace (ZM-30-16), and evacuate to a vacuum degree of 5×10 -3 Pa, at a heating rate of 6°C / min, heat preservation at 450°C for ...

Embodiment 3

[0061] Raw materials: Ti powder and Nb powder are both 75 μm irregular powders with a purity of over 99.9%, and the alcohol is analytically pure.

[0062] Proportion weighing: Ti powder: Nb powder is calculated as 68; 32 by mass ratio, and the amount of alcohol added is 2.5wt% of the sum of the mass of Ti powder and Nb powder.

[0063] Alloying by high-energy ball milling: put the weighed raw materials in a 250ml stainless steel vacuum ball mill tank, use stainless steel balls with a diameter of 15mm for the grinding balls, the weight of the balls is 300g, the ball-to-material ratio is 10:1, and vacuum the ball mill tank. Put it in a planetary ball mill (QM-3SP2) and ball mill it at a speed of 200r / min for 10 hours to obtain a fully alloyed powder.

[0064] Pre-firing: Put the alloy powder obtained by ball milling into a porcelain crucible, place it in a high-vacuum vertical sintering furnace (ZM-30-16), and evacuate to a vacuum degree of 1×10 -2 Pa, with a heating rate of 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com