Method for melting a pseudo beta-titanium alloy comprising (4.0-6.0)% Ai-(4.5-6.0)% Mo-(4.5-6.0)% v-(2.0-3.6)% Cr, (0.2-0.5)% Fe-(0.1-2.0)% Zr

A technology of β-titanium alloy and titanium alloy, which is applied in the field of non-ferrous metallurgy, can solve the problems of increasing oxygen and deteriorating the mechanical properties of titanium alloy, and achieve the effect of high fracture toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Examples of practical embodiments of the invention.

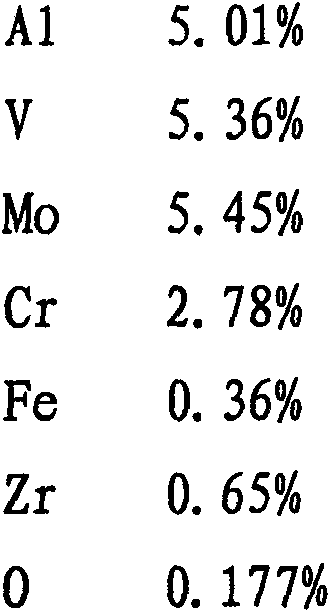

[0037] 1. A 560 mm diameter ingot with the following chemical composition was vacuum arc melted twice:

[0038]

[0039] The ingots were converted into billets of 250mm diameter and subsequently tested for metallic properties. The following results of mechanical properties were obtained after appropriate heat treatment:

[0040] Tensile strength of 1293MPa

[0041] Yield strength of 1239MPa

[0042] 2% elongation

[0043] 4.7% reduction in area

[0044] Fracture toughness of 66.3MPa√m

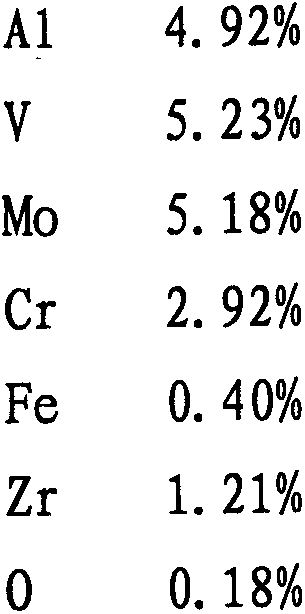

[0045] 2. Vacuum arc melting was performed twice on a 190mm diameter ingot having the following chemical composition:

[0046]

[0047] The ingots were converted into rods with a diameter of 32mm and the metal properties were subsequently tested. The following results of mechanical properties were obtained after appropriate heat treatment:

[0048] Tensile strength of 1427MPa

[0049] Yield strength of 1382MPa

[0050]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com