Processing method for beta titanium alloy wires used for glass frames

A beta titanium alloy and processing method technology, applied in metal processing equipment, metal extrusion, manufacturing tools, etc., can solve the problems of poor wire surface quality, low production efficiency, environmental pollution, etc., and achieve good surface quality and production efficiency. High, avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

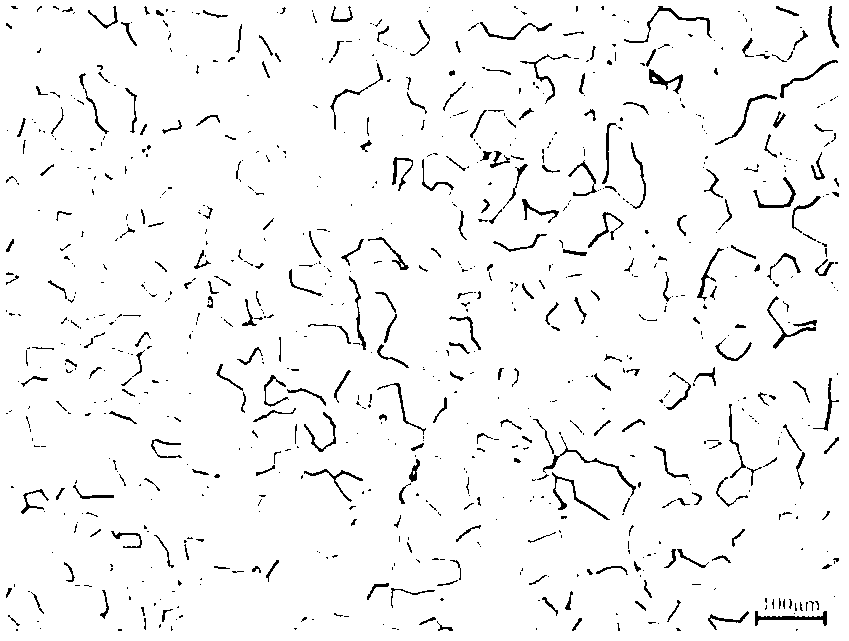

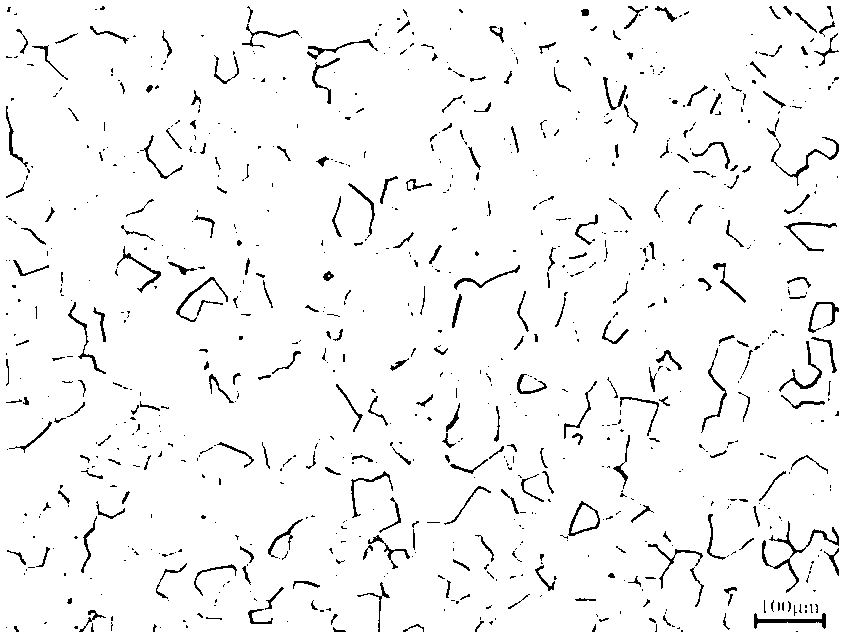

Image

Examples

Embodiment 1

[0029] Step 1, the diameter The TB5 titanium alloy wire billet was peeled off by a centerless lathe to remove oxide skin, rolling cracks and folding defects, and then polished on a thousand impeller wire polishing machine to remove peeling residues and spiral lines, and obtained TB5 titanium alloy wire;

[0030] Step 2, the β titanium alloy wire obtained in step 2 is cold-drawn on a roller die wire drawing machine to That is, when the processing rate is 53%, in the ultrasonic cleaning machine, clean it with a cleaning liquid mixed with a volume ratio of 1:20 detergent and hot water, remove surface oil, rinse with clean water, dry, and then The intermediate vacuum annealing is carried out in the vacuum furnace, and the process is as follows: the vacuum furnace is evacuated to a vacuum degree of 5×10 -2 After Pa is above, the temperature is raised to 780°C, and after holding the heat for 30 minutes, immediately fill the vacuum furnace with argon for forced cooling; TB5 ti...

Embodiment 2

[0033] Step 1, the diameter The Ti-20V-4Al-1Sn titanium alloy wire billet was peeled off by a centerless lathe to remove oxide skin, rolling cracks and folding defects, and then polished on a thousand impeller wire polishing machine to remove peeling residues and spiral lines, and obtained Ti-20V-4Al-1Sn titanium alloy wire;

[0034] Step 2, the β titanium alloy wire obtained in step 2 is cold-drawn on a roller die wire drawing machine to That is, when the processing rate is 51%, in the ultrasonic cleaning machine, use a cleaning solution mixed with a volume ratio of 1:20 detergent and hot water to clean it, remove the surface oil, rinse it with clean water, dry it, and then clean it. The intermediate vacuum annealing is carried out in the vacuum furnace, and the process is as follows: the vacuum furnace is evacuated to a vacuum degree of 5×10 -2 After Pa is above, the temperature is raised to 750°C, and after holding for 50 minutes, immediately fill the vacuum furnace wi...

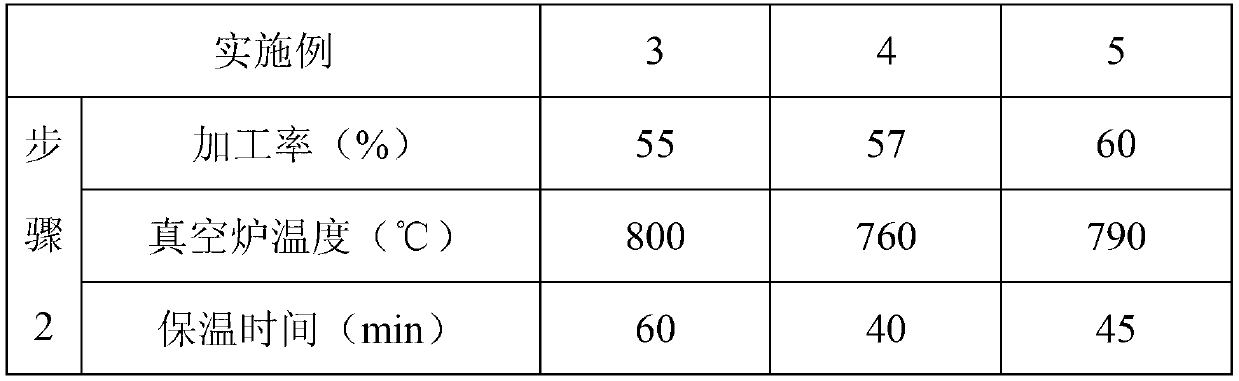

Embodiment 3-5

[0037] Referring to embodiment 2, the process conditions different from embodiment 2 and relevant data are as shown in table 1.

[0038] Process conditions and data of table 1 embodiment 3-5

[0039]

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition point | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com