Multi-layer double-phase cross-scale structure pure titanium and preparation method thereof

A cross-scale, pure titanium technology, applied in the field of metal material processing and preparation or medical surgical implants, to achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for preparing pure titanium with a multi-layer dual-phase cross-scale structure is implemented according to the following specific steps:

[0034] Step 1, room temperature rolling:

[0035] Take a pure titanium plate with a thickness of 8mm as the initial material, cut length × width × height = 40 × 12 × 8mm from the initial material 3 pure titanium plate;

[0036] Adjust the distance between the rolls of the rolling mill to be 8mm, and the rotational speed is equal to 20mm / s.

[0037] Adjust the distance between the rolls to reduce it by 0.1 mm, send the sample into the rolls to complete one pass of rolling, change the feeding direction of the plate, and then carry out the second pass of rolling on the plate.

[0038] Repeat the above rolling process until a pure titanium plate with a thickness of 1 mm is obtained.

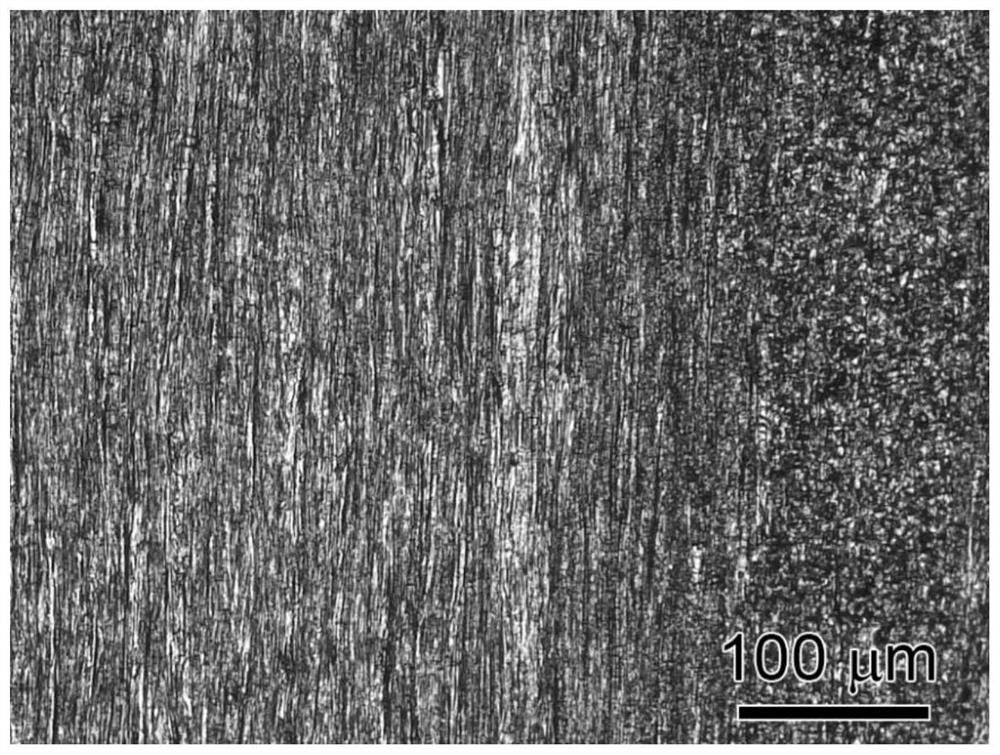

[0039] The microstructure of the room temperature rolled samples consisted of elongated lath-like α grains with an average grain size of abo...

Embodiment 2

[0052] In step 3, the excitation current of the electron beam etching heat treatment is 10mA, and the recovery annealing is as follows: put the sample into a vacuum tube furnace, raise the heating rate from room temperature to 300°C at a heating rate of 8°C / min, keep it warm for 10min, and then heat it at 5°C The cooling rate per minute is reduced to ambient temperature (below 50°C), cooled, and the vacuum tube furnace is filled with gas, and the recovered nanocrystalline α-titanium is taken out. All the other steps are identical to Example 1.

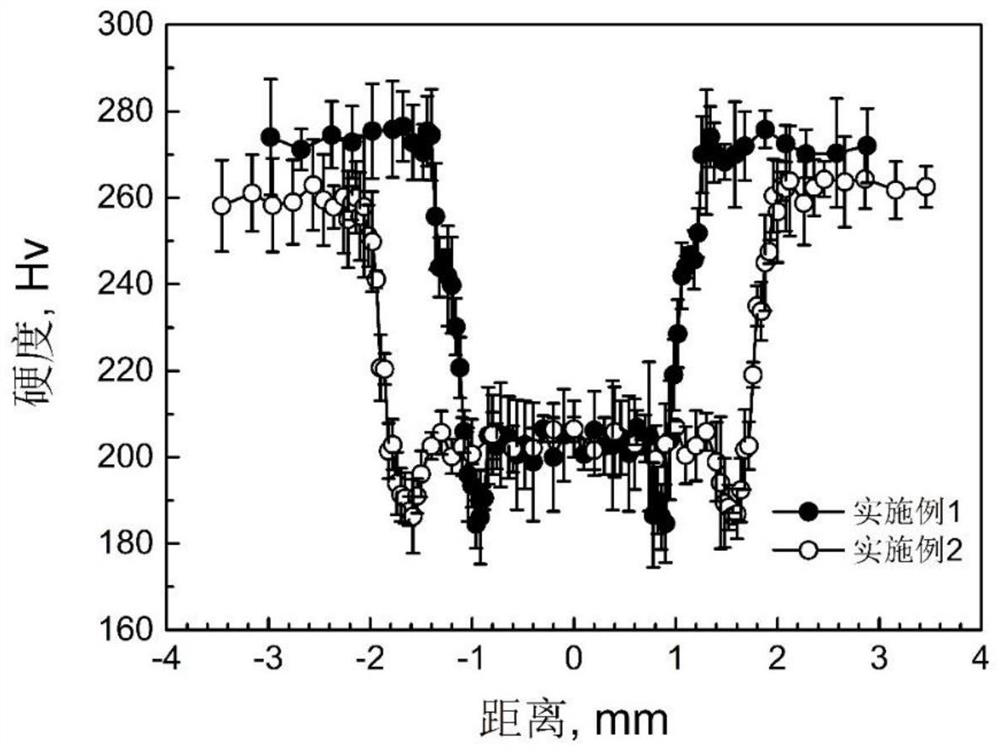

[0053] figure 1 The connecting line of the hollow circle in the above step is the hardness distribution pattern of each layer of the multi-layer dual-phase cross-scale structure pure titanium prepared in the above step Example 2. Compared with Example 1, the hardness value of the matrix nanocrystalline α-titanium is reduced to about 260HV. As it gets closer to the center of the etching heat treatment, the hardness value has a similar ...

Embodiment 3

[0056] In step 3, the excitation current of the electron beam etching heat treatment is 10mA, the moving speed of the electron gun is 2m / min, and the recovery annealing is: put the sample into a vacuum tube furnace, and raise the heating rate from room temperature to 200°C at a heating rate of 10°C / min , keep warm for 10 minutes, then lower the temperature below 50°C at a cooling rate of 3°C / min, cool down, inflate the vacuum tube furnace, and take out the recovered nanocrystalline α-titanium. All the other steps are identical to Example 1.

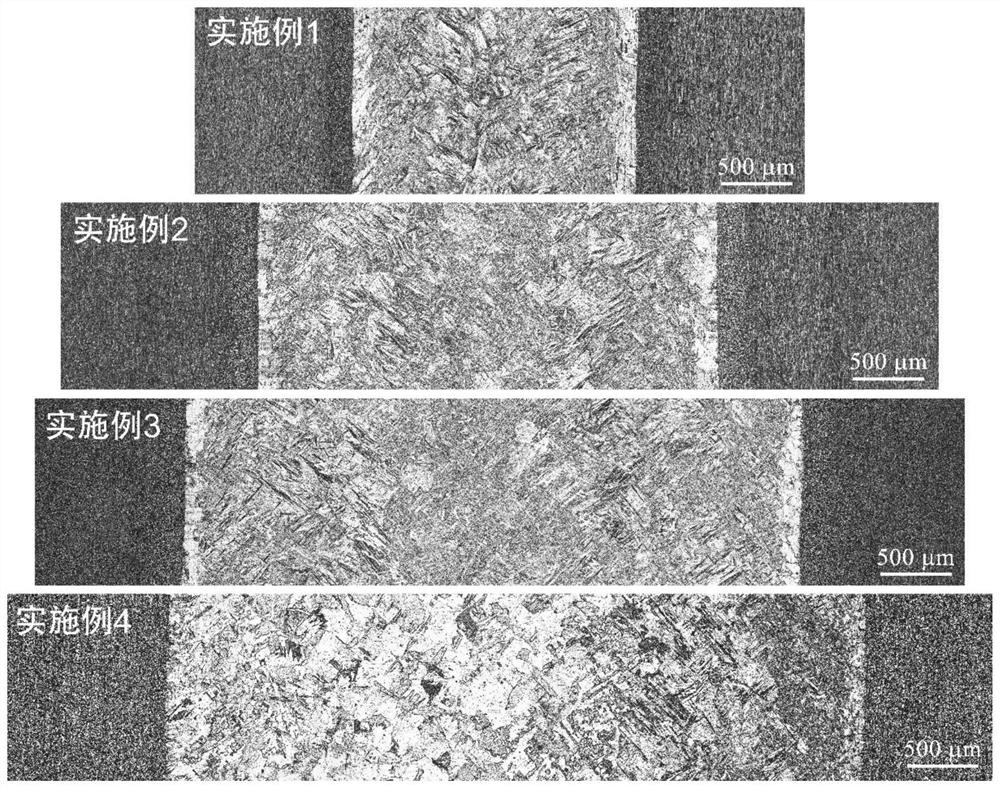

[0057] From Figure 7 It can be seen that, unlike Examples 1 and 2, the matrix nanocrystals in Example 3 do not exist and become completely fine-grained α-Ti, which will lead to a decrease in the overall strength of the sample and cannot maintain nano-crystalline α-Ti-fine-grained α Titanium-coarse-grained β-titanium multilayer dual-phase cross-scale structure. This is because the electron gun moves too slowly and the heat input is too ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com