High strength high elasticity heatproof titanium alloy and preparation method thereof

A titanium alloy and high-elasticity technology, which is applied in the design and preparation of titanium alloy materials, can solve the problems that cannot meet the performance requirements of heat-resistant elastic parts of hypersonic aircraft, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

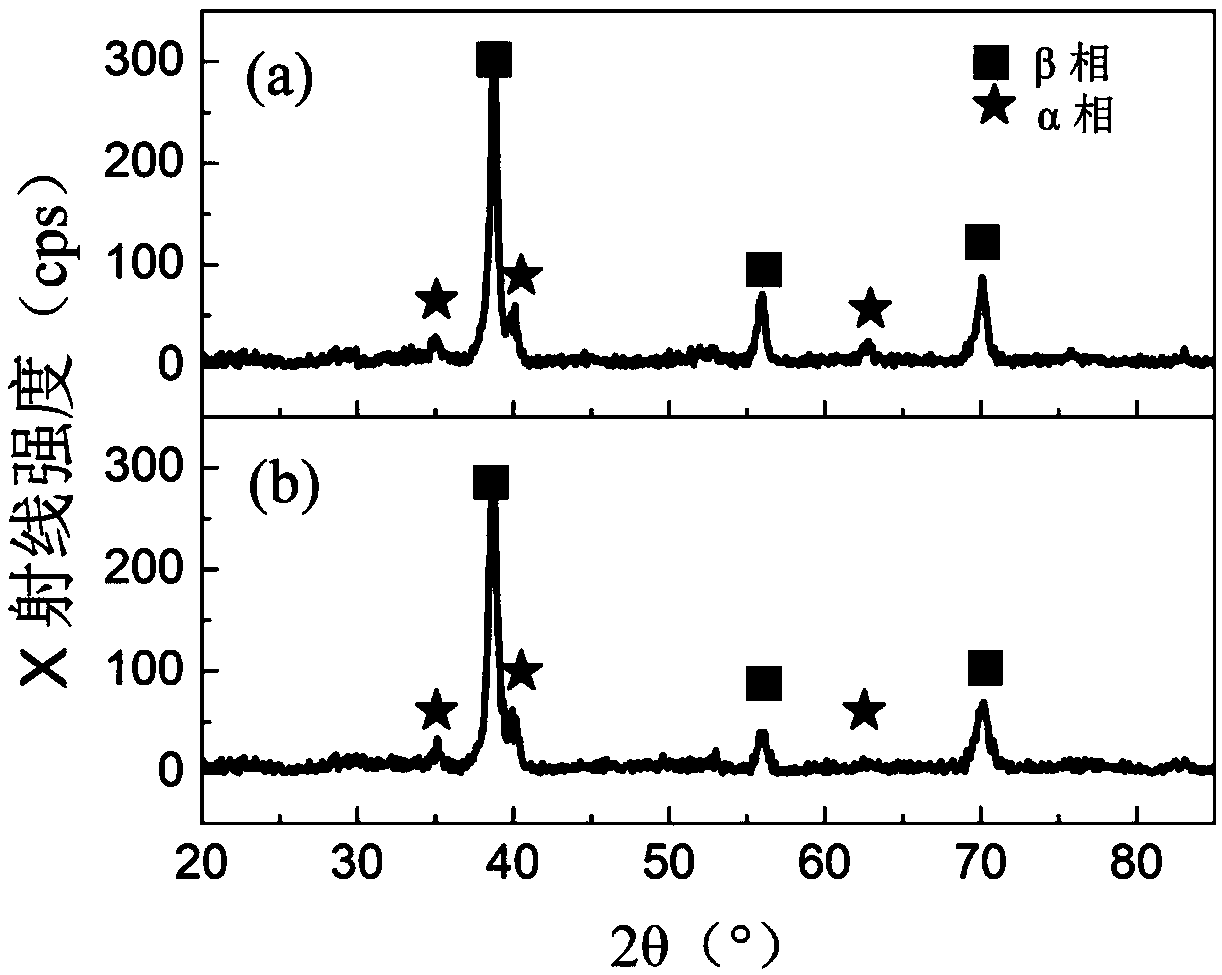

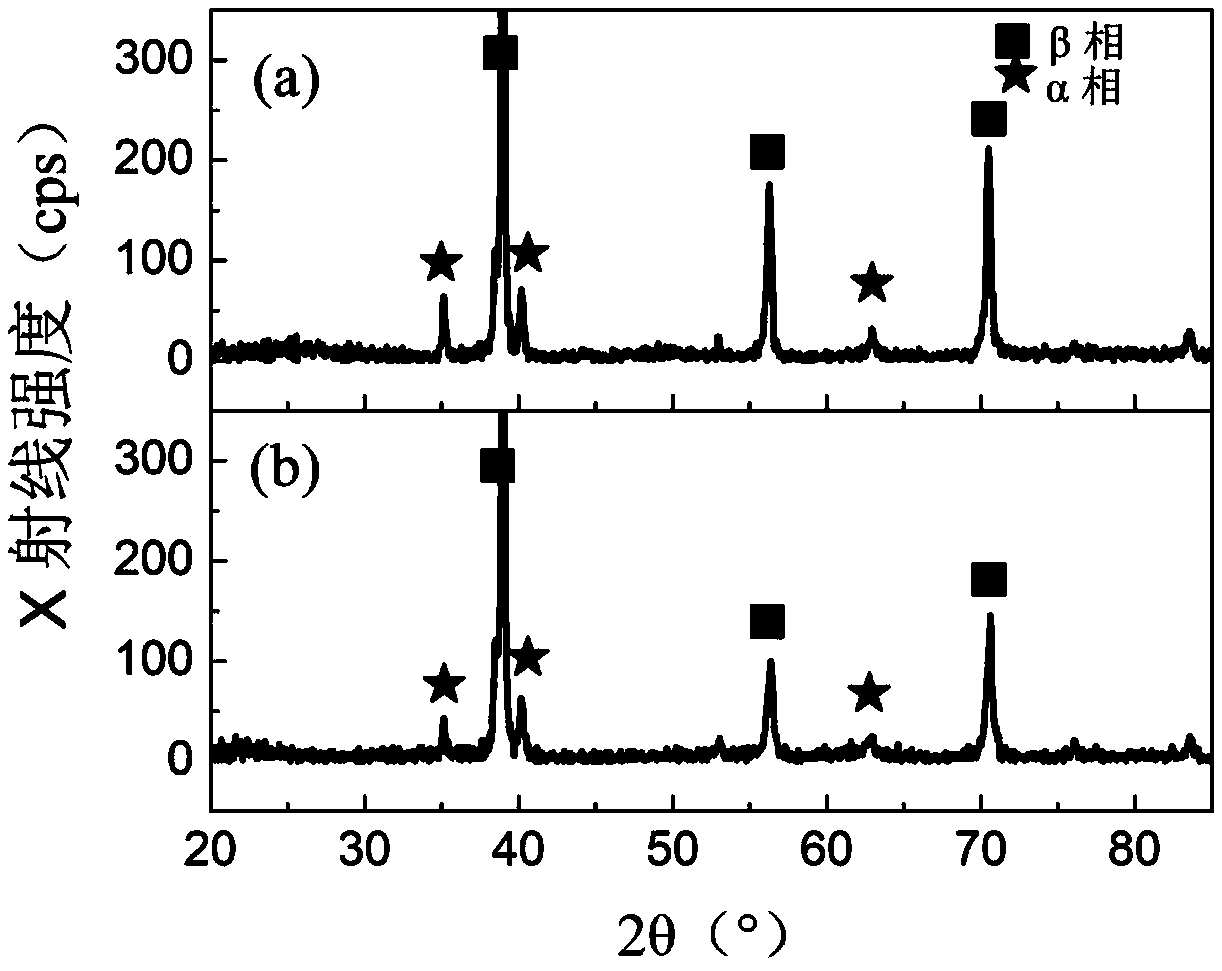

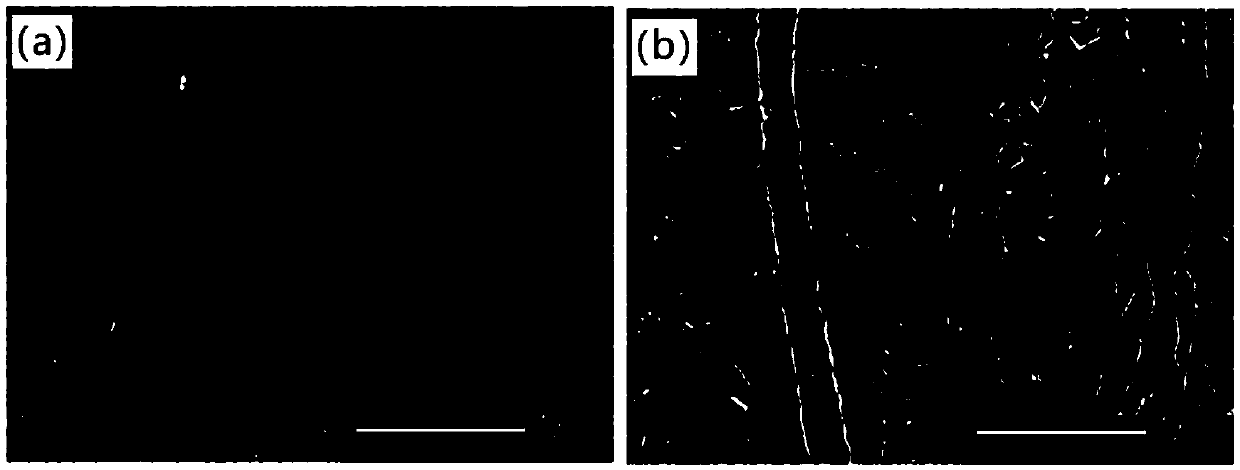

Embodiment 1

[0033] With high purity Ti, Nb, V, Zr and TiO 2 (TiO 2 , Ti: 60%; O: 40%) as the raw material to prepare the alloy, the weight of each component is: Nb: 34.7wt%; V: 0.2wt%; Zr: 1.8wt%; O: 0.30wt%, the balance is Ti. The prepared raw materials are smelted five times in a magnetic stirring vacuum non-consumable arc furnace to obtain an ingot with uniform composition. The ingot was hot forged into a bar at 800°C with a deformation of 85%. After solution treatment at 1000℃ for 50min, it was put into water for quenching and cooling. The bar surface is descaled by turning, and then cold rolled with 80% deformation at room temperature. The rods were placed in a quartz tube to be vacuum-sealed, heated to 490°C for 10h in a heat treatment furnace, and then cooled to room temperature in air. Mechanical properties are: σ b =1131.5MPa, σ 0.2 =1042.5MPa, E=69.5GPa, σ 0.2 / E=1.50%, δ=11.7%.

Embodiment 2

[0035] With high purity Ti, Nb, V, Zr and TiO 2 (TiO 2 , Ti: 60%; O: 40%) as the raw material to prepare the alloy, the weight of each component is: Nb: 32.0wt%; V: 2.0wt%; Zr: 2.2wt%; O: 0.31wt%, the balance is Ti. The prepared raw materials are smelted five times in a magnetic stirring vacuum non-consumable arc furnace to obtain an ingot with uniform composition. The ingot was hot forged into a bar at 830°C with a deformation of 75%. After solution treatment at 970℃ for 55min, it was put into water for quenching and cooling. Turning to remove scale on the surface of the bar, followed by cold rolling at room temperature with a deformation of 85%. The rods were placed in a quartz tube to be vacuum-sealed, heated to 510 °C in a heat treatment furnace for 9 h, and then cooled to room temperature in air. Mechanical properties are: σ b =1149.3MPa, σ 0.2 =1058.5MPa, E=70.1GPa, σ 0.2 / E=1.51%, δ=11.0%.

Embodiment 3

[0037] With high purity Ti, Nb, V, Zr and TiO 2 (TiO 2 , Ti: 60%; O: 40%) as the raw material to prepare the alloy, the weight of each component is: Nb: 29.0wt%; V: 4.0wt%; Zr: 2.0wt%; O: 0.30wt%, the balance is Ti. The prepared raw materials are smelted five times in a magnetic stirring vacuum non-consumable arc furnace to obtain an ingot with uniform composition. The ingot was hot forged into a bar at 900°C with a deformation of 80%. After solution treatment at 930℃ for 55min, it was put into water for quenching and cooling. The bar surface is descaled by turning, and then subjected to cold rolling deformation at room temperature with a deformation amount of 90%. The bar was placed in a quartz tube to be vacuum-sealed, heated to 510 °C in a heat treatment furnace for 8 h, and then cooled to room temperature in air. Mechanical properties are: σ b =1134.8MPa, σ 0.2 =1046.5MPa, E=68.4GPa, σ 0.2 / E=1.53%, δ=11.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com