GOLF CLUB HEAD ALLOY AND METHOD FOR manufacturing SAME

A technology of golf club head and manufacturing method, which is applied in the field of alloys and its manufacturing, can solve the problems of increasing the hitting distance, increasing the spring effect of the hitting surface, and being unable to find it, so as to achieve the effect of increasing the spring effect and increasing the hitting distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

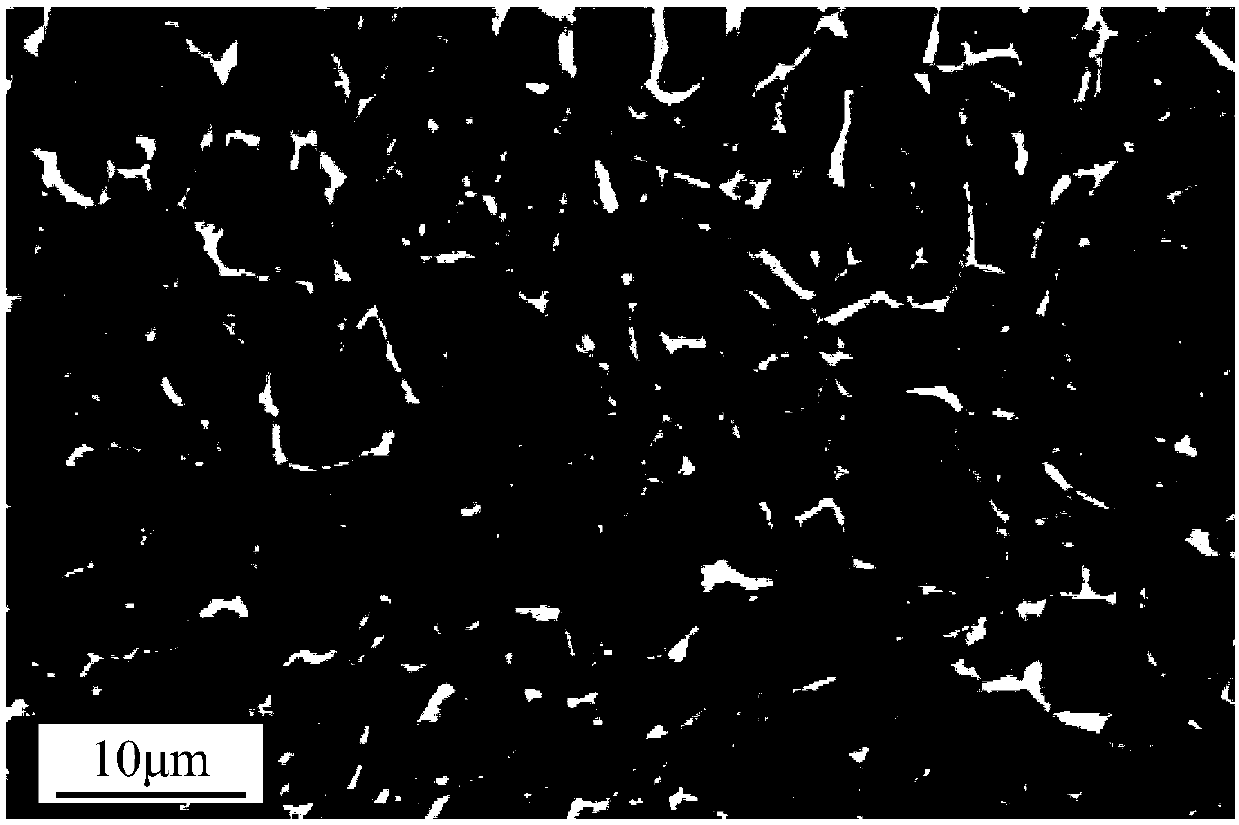

[0051] An alloy blank is provided, the alloy blank comprises 86.78 parts by weight of titanium, 2.8 parts by weight of zirconium, 5.1 parts by weight of aluminum, 0.03 parts by weight of carbon, 0.03 parts by weight of nitrogen, 0.06 parts by weight of oxygen, 1.5 parts by weight of chromium, 1.6 parts by weight iron, 1.0 parts by weight vanadium and 1.1 parts by weight molybdenum. Next, a hot rolling process is performed on the alloy blank at 850 to 950° C. to form the golf club head alloy (for example, rolled into a plate), wherein a crystal phase composition of the golf club head alloy is It includes an equiaxed double-phase structure, wherein the equiaxed double-phase structure includes an alpha titanium phase and a beta titanium phase.

Embodiment 2 to 6 and comparative example 1 to 3

[0053] The production methods of Examples 2 to 6 and Comparative Examples 1 to 3 are roughly the same as that of Example 1, but the proportions of ingredients used are different, as shown in Table 1 below (the unit of each ingredient is parts by weight (or wt%)).

[0054] Table 1

[0055]

[0056] Next, the mechanical properties of Examples 1 to 6 and Comparative Examples 1 to 3 were analyzed. The analysis results are shown in Table 2 below.

[0057] Table 2

[0058]

[0059]

[0060] As can be seen from the analysis results of the above table 2, embodiments 1 to 6 do possess low Young's modulus (between 80 and 100GPa), high tensile strength (between 1100 and 1250MPa), high yield strength (between 1000 to 1050MPa), and acceptable elongation. The mechanical properties of Comparative Examples 1 to 3 are high Young's modulus, low tensile strength and low yield strength, and the elongation of Comparative Examples 2 and 3 is too high, so Comparative Examples 1 to 3 do n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com