Composite cover plate, and golf club head assembled therewith

A golf club head and cover plate technology, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems of unfavorably increasing the added value of golf club heads, low golf club heads, monotonous colors and textures, etc. The effect of adding added value, lowering the position of the center of gravity, and increasing the adjustment margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

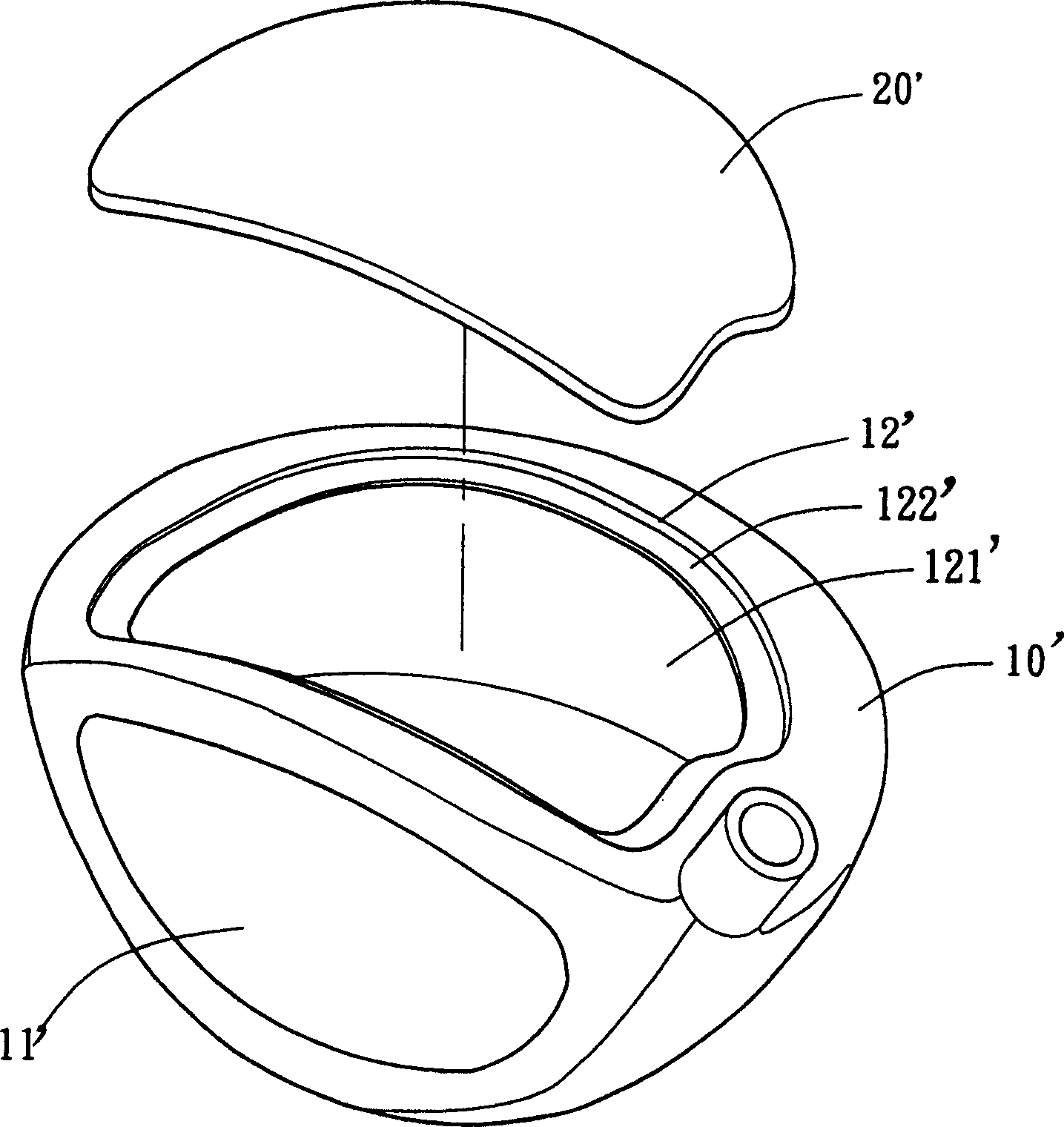

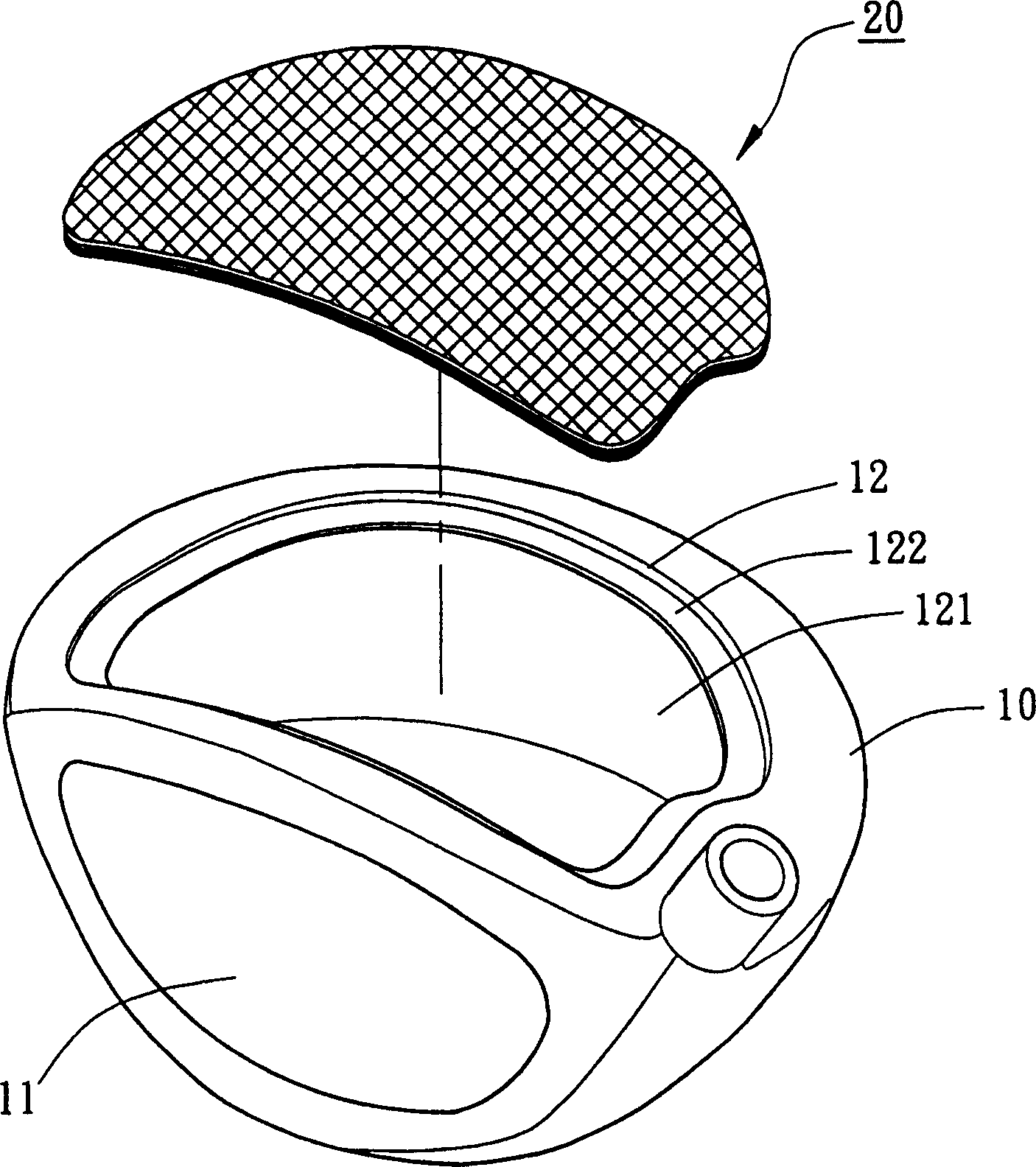

[0046] Such as figure 2 As shown, the golf club head equipped with a composite cover of the present invention includes a body 10 and at least one composite cover 20.

[0047] The main body 10 is made of metal material, and is provided with a ball striking panel 11 and at least one cavity 12 thereon.

[0048] The cavities 12 are selectively formed at other suitable positions on the main body 10 except for the ball striking panel 11, such as the positions of the top plate, the bottom plate or the side plate.

[0049]The cavity 12 has an opening 121 and a step 122 protruding from the inner periphery of the opening 121.

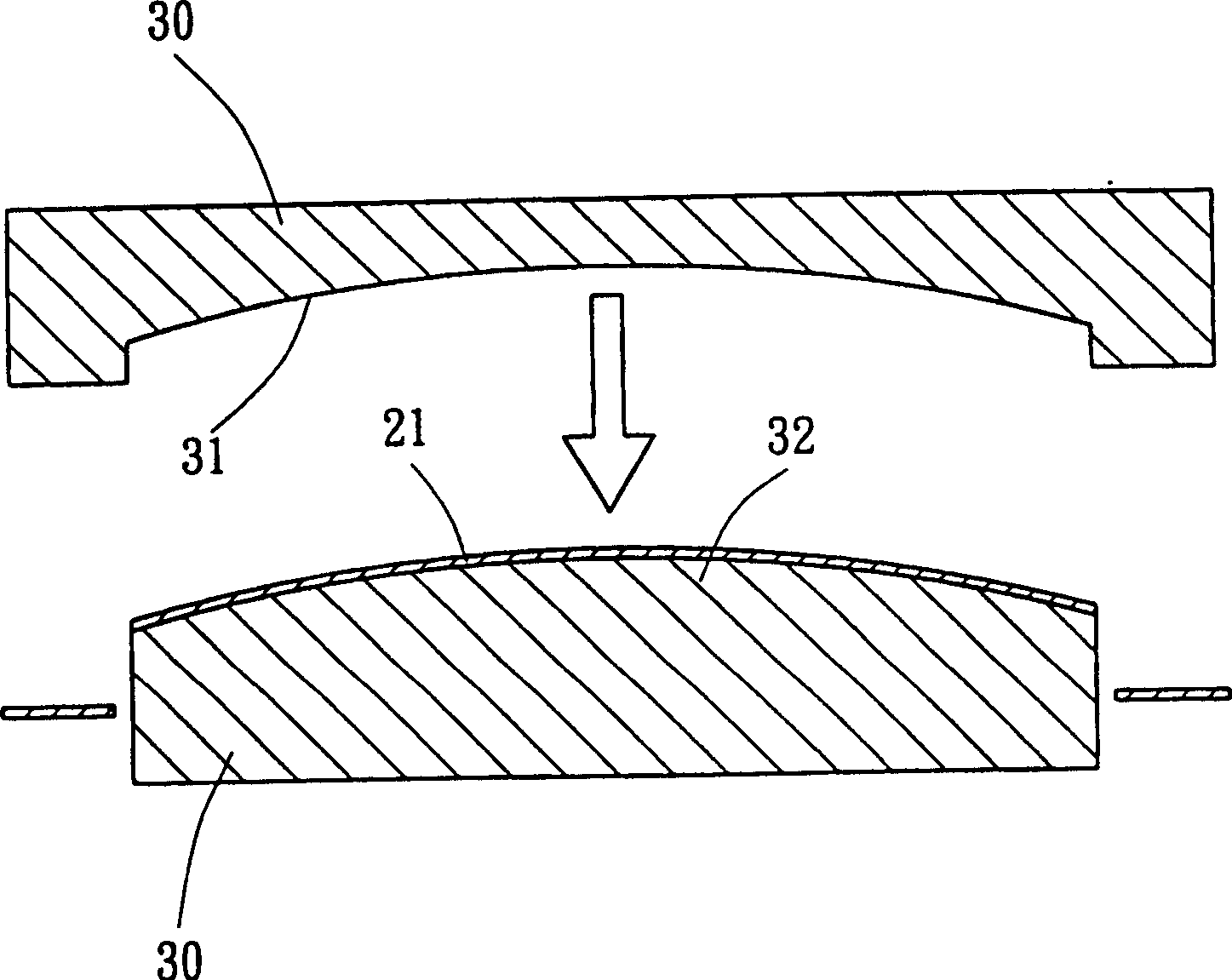

[0050] Such as Figure 5 , Figure 6 As shown, the outer periphery of the composite cover plate 20 corresponds to the inner periphery of the cavity 12 on the body 10. When assembling, with the aid of epoxy resin and other adhesives, the composite cover plate 20 can be firmly and tightly glued and bonded in the cavity 12 of the main body 10 to form the composite cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com