Hollow wood golf club head structure

A club head and wood technology, which is applied in the field of hollow wood club head structure, can solve the problems of easily affecting the hitting performance and residual welding material, etc., so as to save the weight of the wood club, reduce the number of welding parts, and increase the directional stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

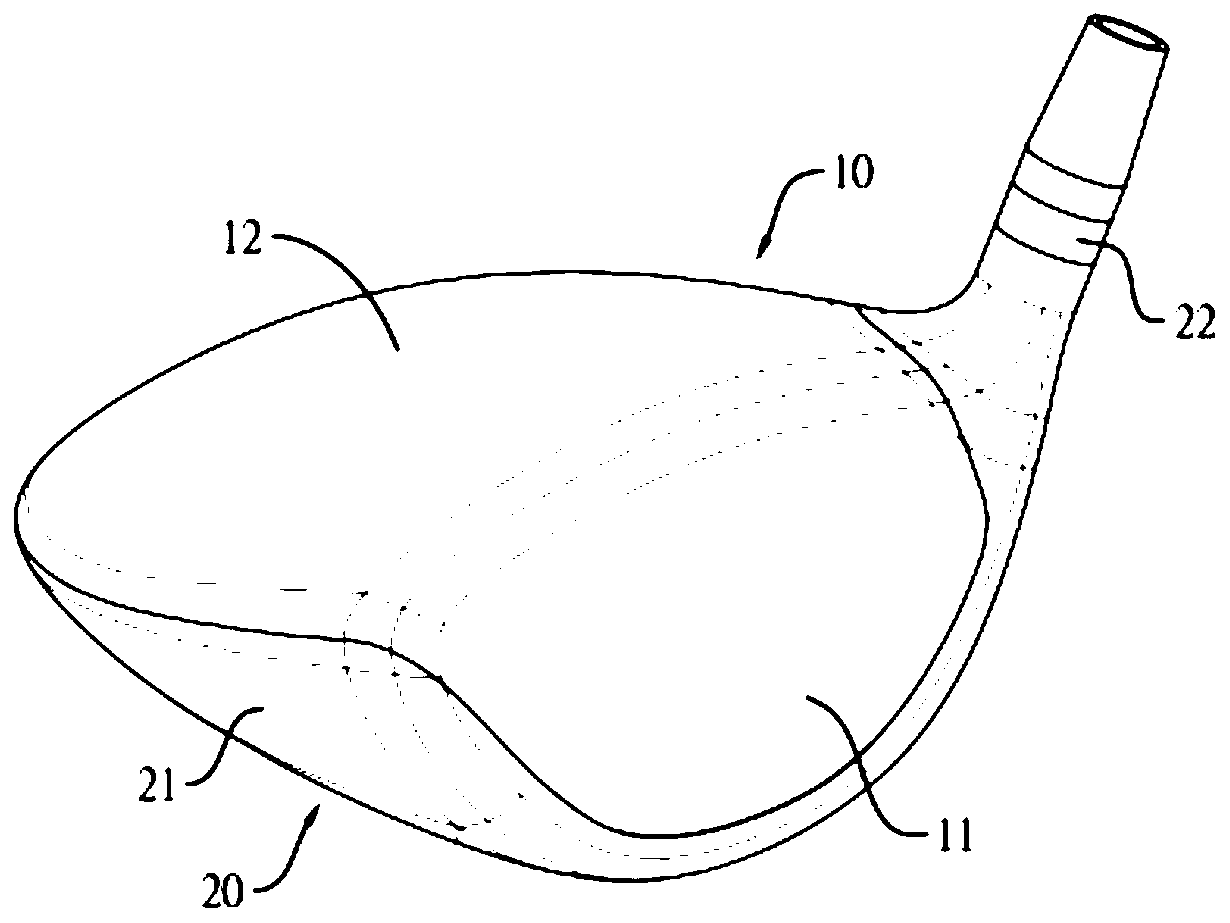

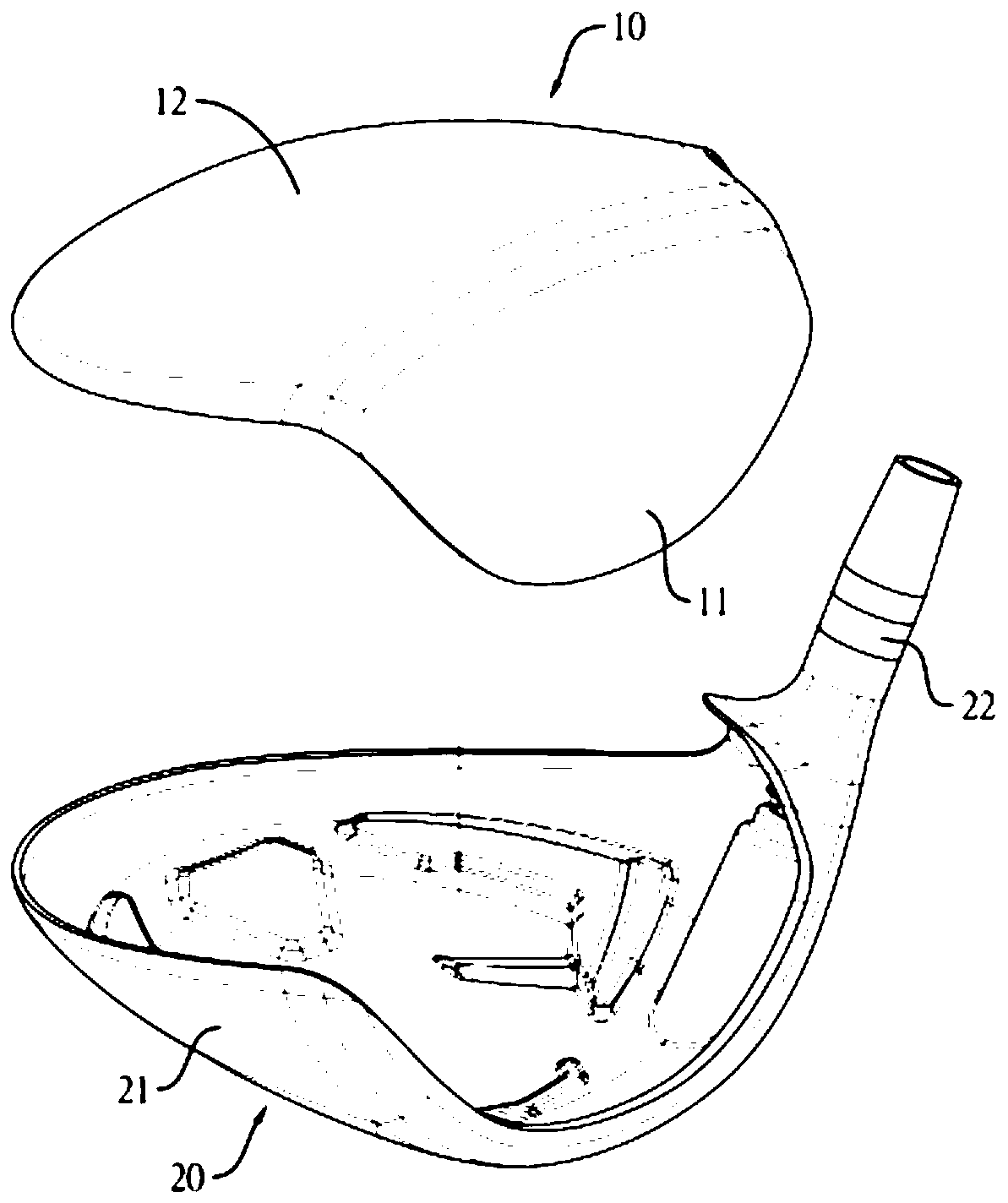

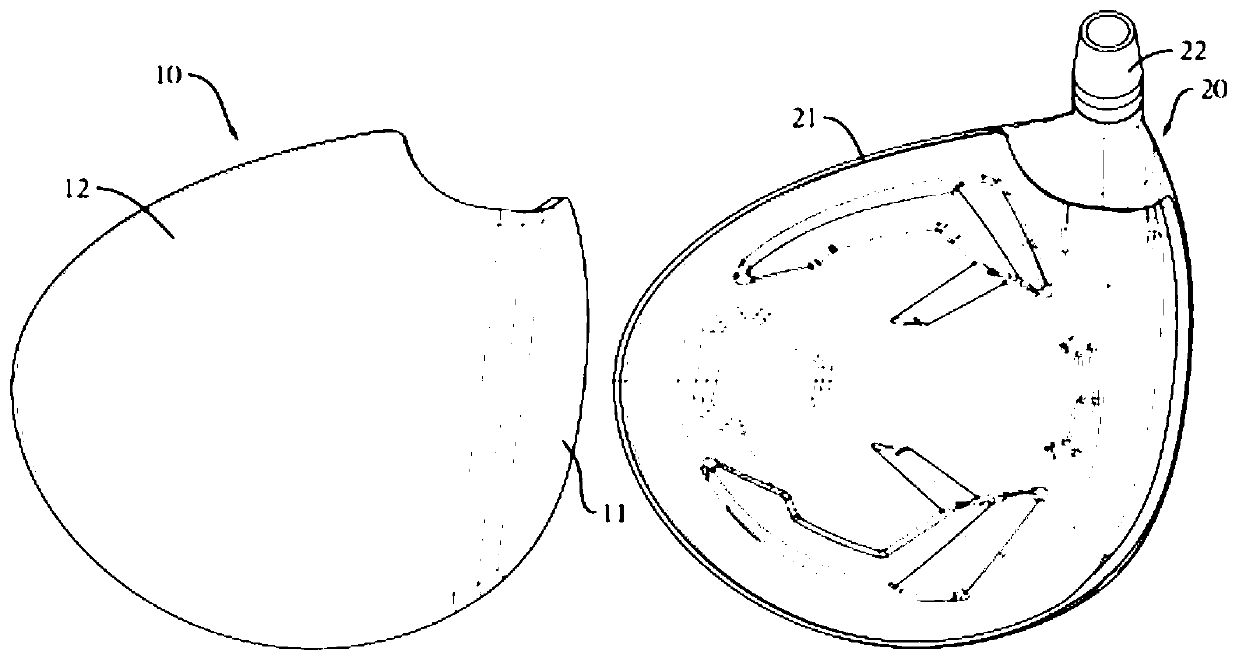

[0031] like Figure 1 to Figure 4 and Image 6 As shown, several preferred embodiments of the hollow wood club head structure of the present invention are disclosed. As can be seen from these drawings, the hollow wood club head structure includes a ball striking part 10, 10A and a club head body 20, 20A.

[0032] like Figure 1 to Figure 4 and Image 6 As shown, the ball striking parts 10, 10A are forged parts, which include a ball striking face plate part 11, 11A (Face) and a crown part 12, 12A (Crown), the crown parts 12, 12A (Crown) integrally formed in the The top ends of the striking face parts 11 and 11A extend rearward.

[0033] In this preferred embodiment, in the forged ball striking parts 10 and 10A, the thickness of the crown parts 12 and 12A is 0.4mm-1.2mm, and the thickness of the ball-hitting face plate parts 11 and 11A is 1.60mm-5.5mm. . The ball striking face portion 11, 11A may be a shape of uniform thickness, or, as Figure 5 As shown, the batting surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com