Iron golf club head with hardened layer

A golf ball and hardened layer technology, which is applied to golf balls, golf clubs, sports accessories, etc., can solve the problems of restricting the position of the center of gravity of the golf iron head, failing to meet the needs of users, and affecting the user's feel of playing, etc. Achieve the effects of providing center of gravity changeability, material saving, and good grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

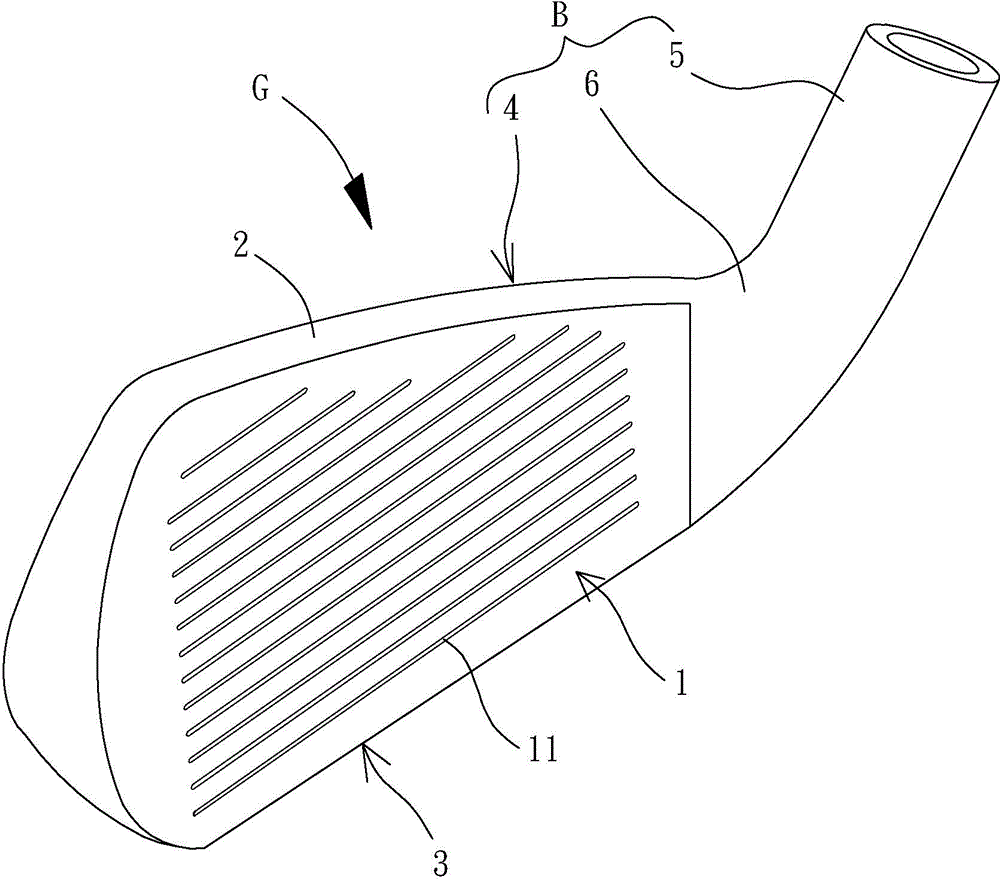

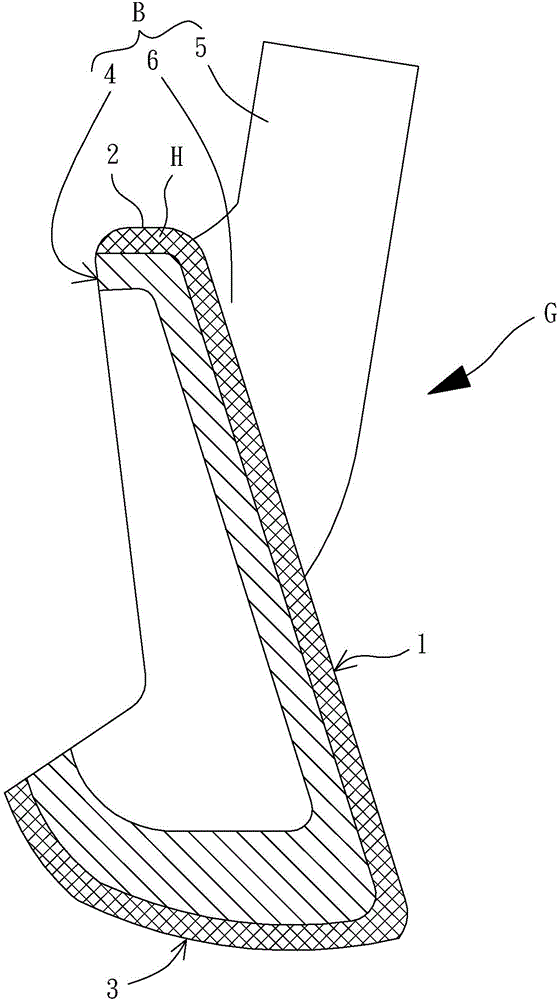

[0032] Please refer to figure 1 As shown, this is a three-dimensional appearance view of a golf iron club head with a hardened layer according to the present invention. The golf iron club head G includes a face 1, a blade 2, a sole 3, A back (back) 4, a pipe handle (hosel) 5 and a neck (neck) 6. The hitting panel part 1 is the part where the golf iron club head G contacts with a golf ball. The hitting panel part 1 is preferably provided with at least one line of grooves 11. The opposite sides of the hitting panel part 1 are respectively connected with the The knife part 2 and the bottom part 3, and the opposite side of the striking panel 1 is the back part 4, the handle part 5 is connected to the striking panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com