Self-controlled flow test device

A flow test device and self-control technology, which is applied to the volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring the pressure difference. Does not have the problem of automatic test function, etc., to achieve the effect of reliable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

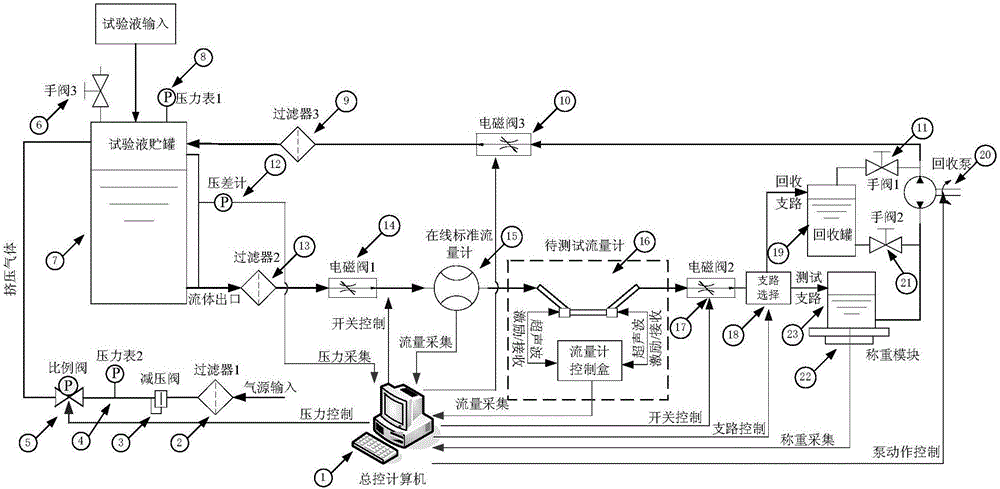

[0029] The basic idea of the present invention is: a self-control flow test device is proposed, the device includes a master control computer, a filter 1, a pressure reducer, a pressure gauge 2, a proportional valve, a hand valve 3, a test liquid storage tank, and a pressure gauge 1 , filter 3, solenoid valve 3, hand valve 1, differential pressure gauge, filter 2, solenoid valve 1, standard flow meter, flow meter to be tested, solenoid valve 2, branch selector, recovery tank, recovery pump, hand Valve 2, weighing module, and test weighing tank; this test device is compatible with special media such as propellant simulation liquid and real propellant. Through the large-scale rough pressure adjustment of the pressure reducer and the small-scale fine pressure adjustment of the proportional valve, the gas pressure of the test liquid storage tank is stabilized within a specific range, which meets the stability requirements of the constant flow test. Through the real-time collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com