Method of hardening a beta titanium member

a beta titanium and hardening technology, applied in the direction of metallic material coating process, solid-state diffusion coating, coating, etc., can solve the problems of low wear resistance of titanium alloy, high surface processing difficulty of either material, poor adhesion between the plating layer and the titanium surface,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

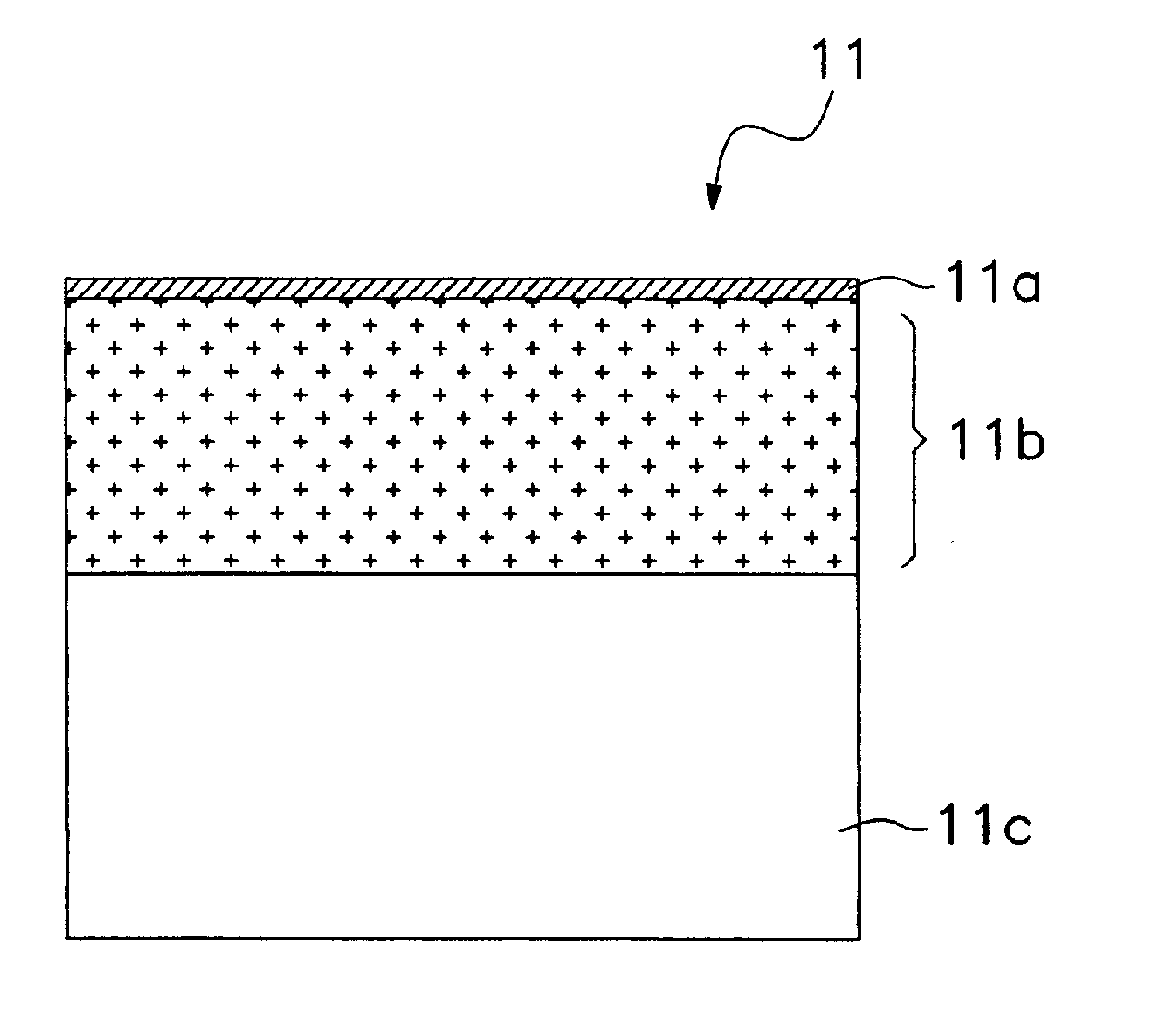

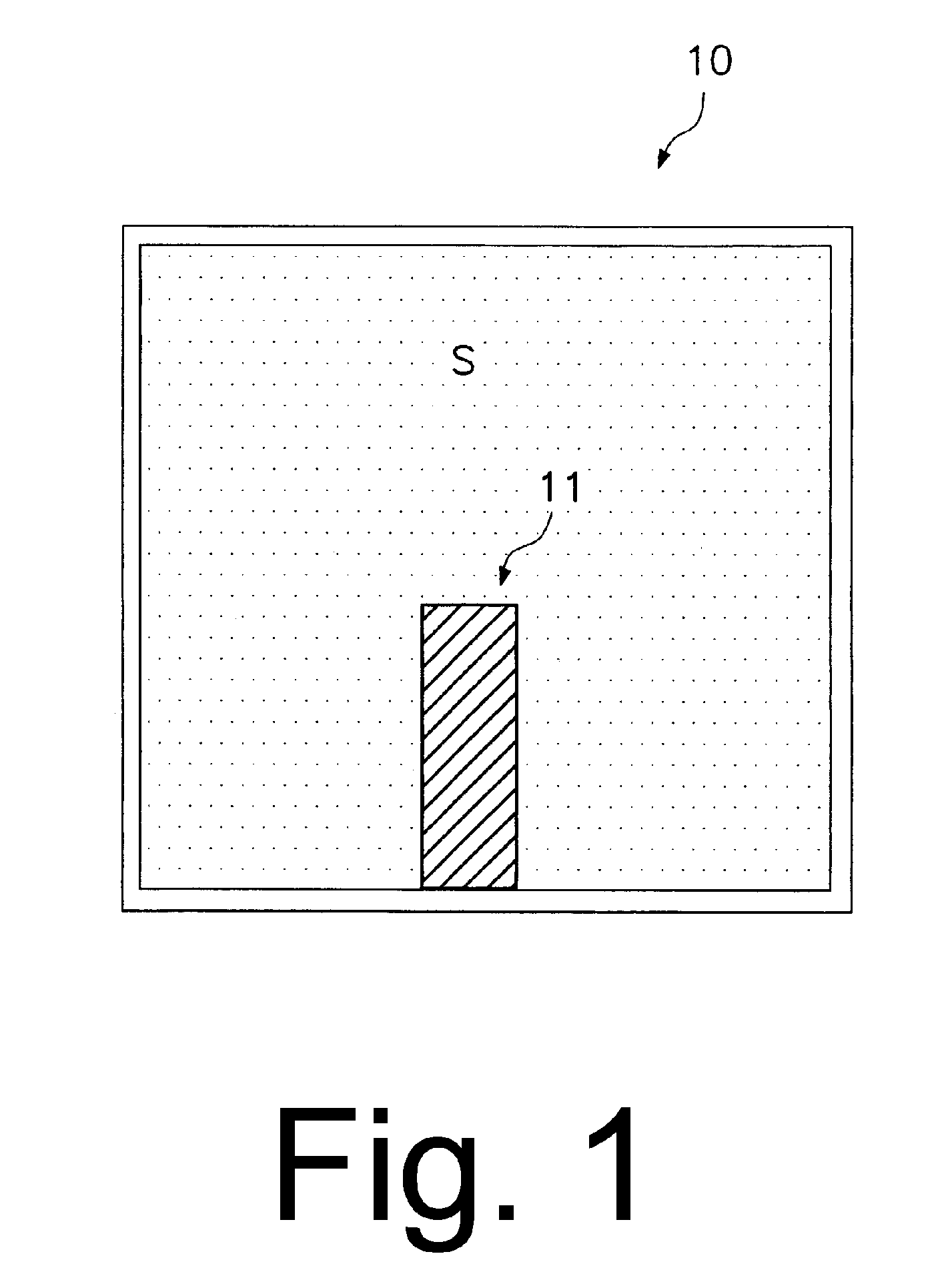

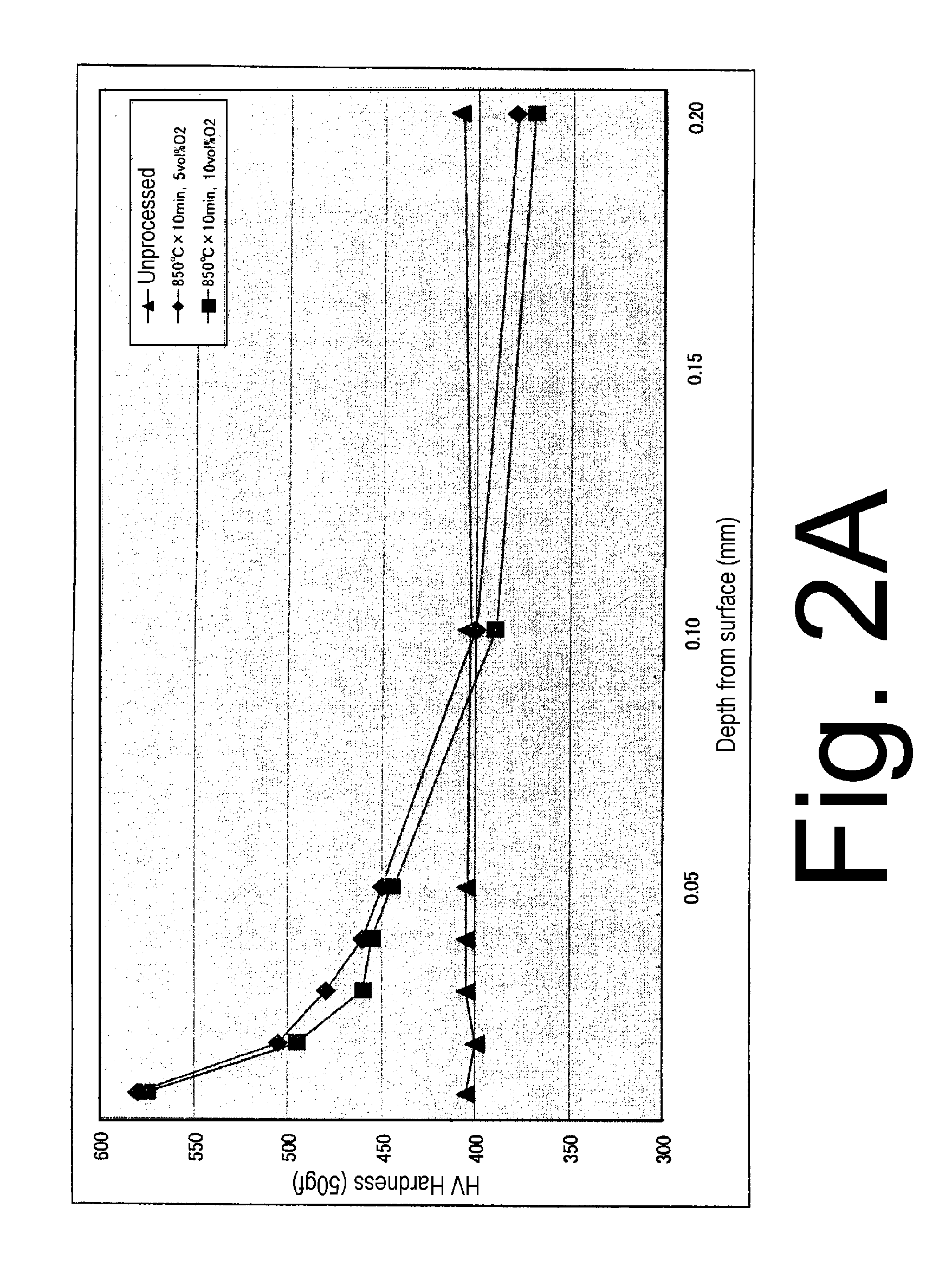

[0011]FIG. 1 shows the basic construction of a particular embodiment of a beta titanium surface hardening apparatus 10 in the form of a titanium melting furnace for surface hardening a beta titanium member 11. In general, beta titanium member 11 is placed in a processing chamber S of beta titanium surface hardening apparatus 10, and then beta titanium member 11 is heated in an atmosphere comprising a gas mixture comprising oxygen and an inert gas such as argon gas. As a result, heat processing can be carried out in an atmosphere having a lower oxygen concentration than ordinary atmospheric air. In this embodiment, the oxygen concentration ranges from approximately 0.05 vol % to approximately 20 vol % (preferably approximately 1.0 vol % to approximately 10 vol %), the heating temperature ranges from approximately 700° C. to approximately 1000° C. (preferably approximately 850° C. to approximately 950° C.), and the heat processing time ranges from approximately 10 minutes to approxima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com