Aluminum-vanadium-niobium intermediate alloy, aluminum-vanadium-niobium-titanium intermediate alloy and preparation methods of aluminum-vanadium-niobium intermediate alloy and aluminum-vanadium-niobium-titanium intermediate alloy

A master alloy, aluminum vanadium technology, applied in the field of aluminum vanadium niobium master alloy, aluminum vanadium niobium titanium master alloy and its preparation, can solve the problems of product structure, influence of mechanical performance reliability, complex alloy ratio, segregation, inclusion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a method for preparing the aluminum vanadium niobium master alloy described in the above technical solution, comprising the following steps:

[0031] Mix vanadium pentoxide, niobium pentoxide and aluminum for aluminothermic reaction, and cool to obtain aluminum vanadium niobium primary alloy;

[0032] The aluminum vanadium niobium primary alloy and aluminum are subjected to vacuum induction melting and cooled to obtain the aluminum vanadium niobium master alloy.

[0033] The invention mixes vanadium pentoxide, niobium pentoxide and aluminum for aluminothermic reaction, and obtains aluminum vanadium niobium primary alloy after cooling.

[0034] In the present invention, the mass ratio of vanadium pentoxide, niobium pentoxide and aluminum is preferably (1.561-1.673): (0.179-0.268): (0.980-1.020), more preferably (1.584-1.651): (0.197-0.250): (0.988-1.012), most preferably 1.628:0.232:0.996.

[0035] In the present invention, the vanadium p...

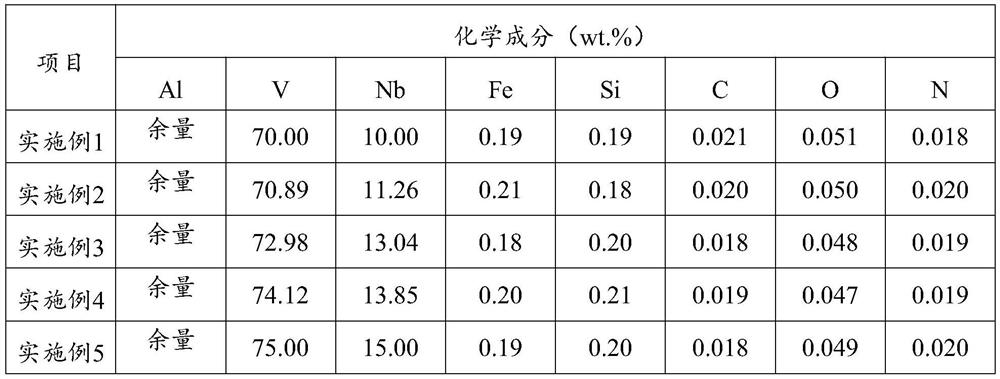

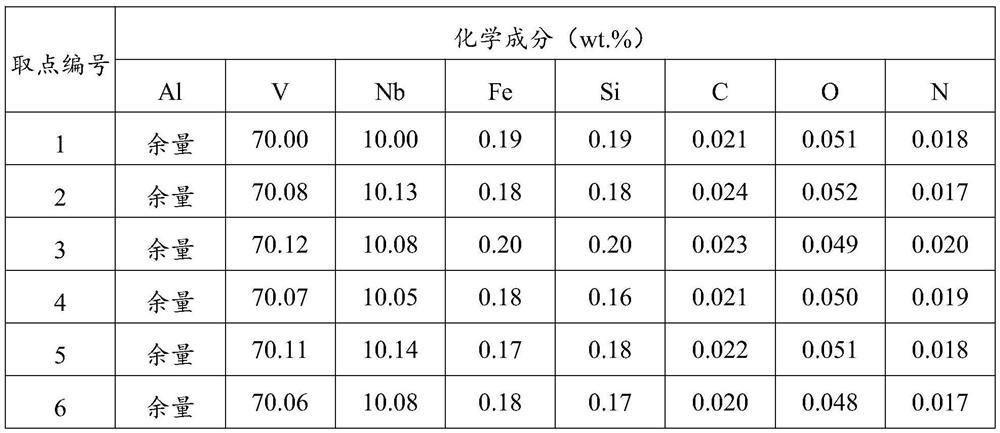

Embodiment 1

[0085] 1. Aluminum thermal smelting process

[0086] (1) Dry the aluminum powder, niobium pentoxide and vanadium pentoxide at a temperature of 120° C. for 12 hours.

[0087] (2) Raw material ratio: aluminum powder 87.60kg, niobium pentoxide 14.30kg, vanadium pentoxide 124.90kg; put the raw materials into a V-shaped mixer, the mixing rate is 140r / min, and the mixing time is 2min, ensuring All raw materials are mixed evenly and fully contacted.

[0088] (3) Put the uniformly mixed charge into the sintered corundum crucible, ignite the reaction, after the reaction is completed, cool with the furnace for 12 hours, remove the crucible, take out the alloy ingot, and weigh it.

[0089] (4) After removing the slag layer and oxide film on the surface of the alloy ingot, crushing and finishing are carried out, and after magnetic separation and manual selection, the primary alloy of aluminum, vanadium and niobium is obtained, and the chemical composition of the obtained primary alloy is...

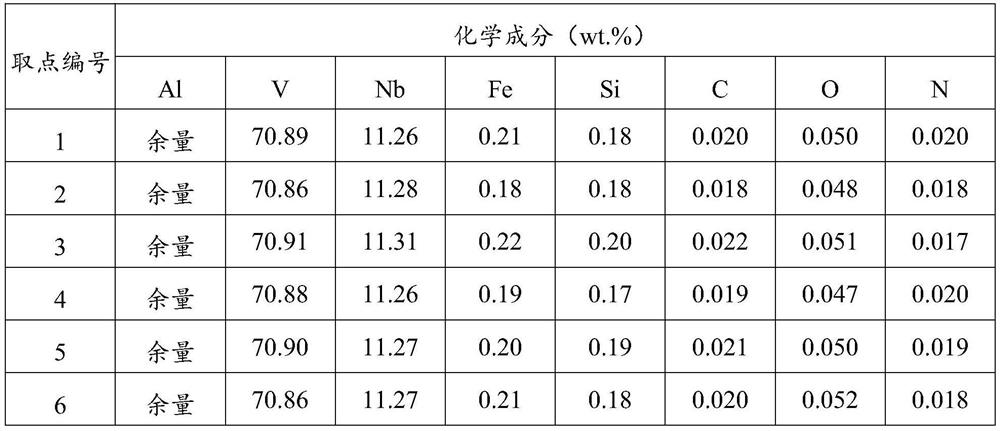

Embodiment 2

[0097] 1. Aluminum thermal smelting process

[0098] (1) Dry the aluminum powder, niobium pentoxide and vanadium pentoxide at a temperature of 120° C. for 12 hours.

[0099] (2) Raw material ratio: 80.97kg of aluminum powder, 15.73kg of niobium pentoxide, and 126.69kg of vanadium pentoxide; put the raw materials into a V-type mixer, the mixing rate is 130r / min, and the mixing time is 3min, ensuring All raw materials are mixed evenly and fully contacted.

[0100] (3) Put the uniformly mixed charge into the sintered corundum crucible, ignite the reaction, after the reaction is completed, cool with the furnace for 12 hours, remove the crucible, take out the alloy ingot, and weigh it.

[0101] (4) After removing the slag layer and oxide film on the surface of the alloy ingot, crushing and finishing are carried out, and after magnetic separation and manual selection, the primary alloy of aluminum, vanadium and niobium is obtained, and the chemical composition of the obtained prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com