Rolling bearing and bearing unit

A bearing device and bearing technology, which is applied in the direction of shafts and bearings, rolling contact bearings, bearing assembly, etc., can solve problems such as enhancement, insufficient restraint of bearing dynamic friction torque, large vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

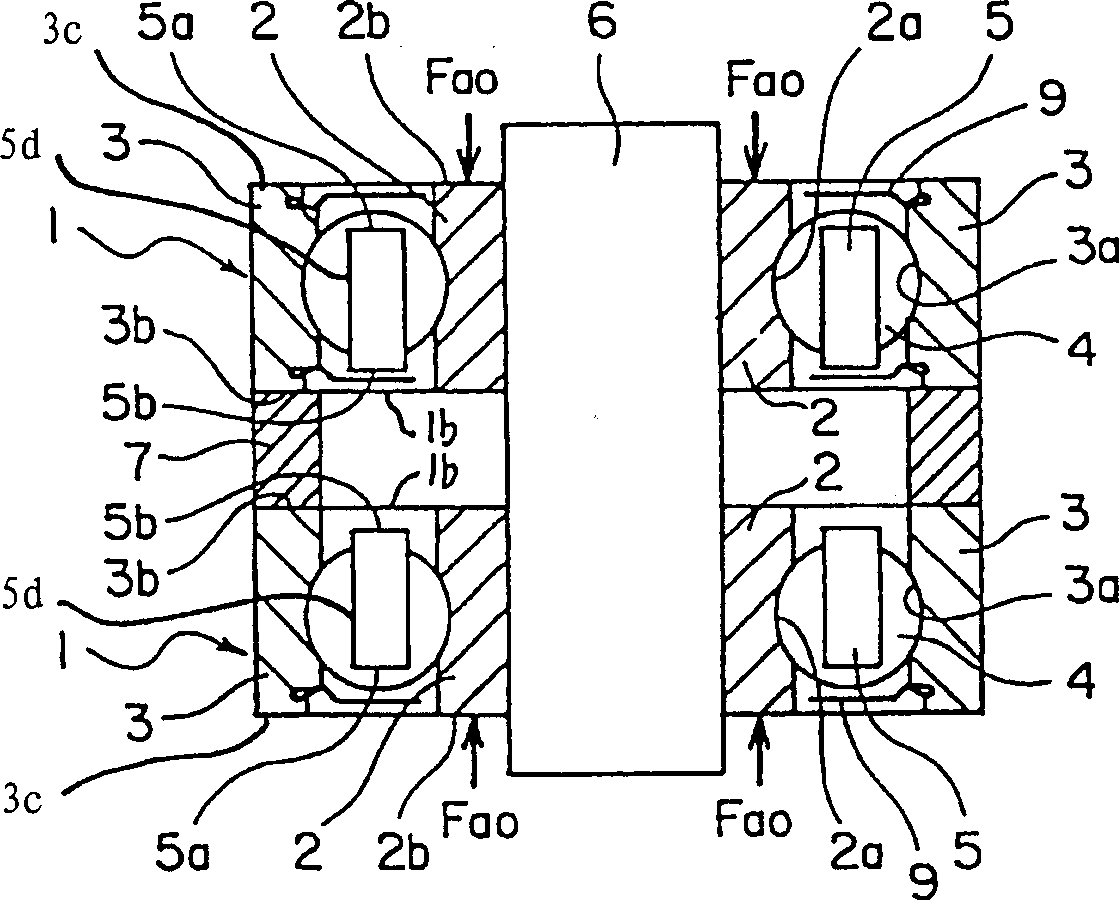

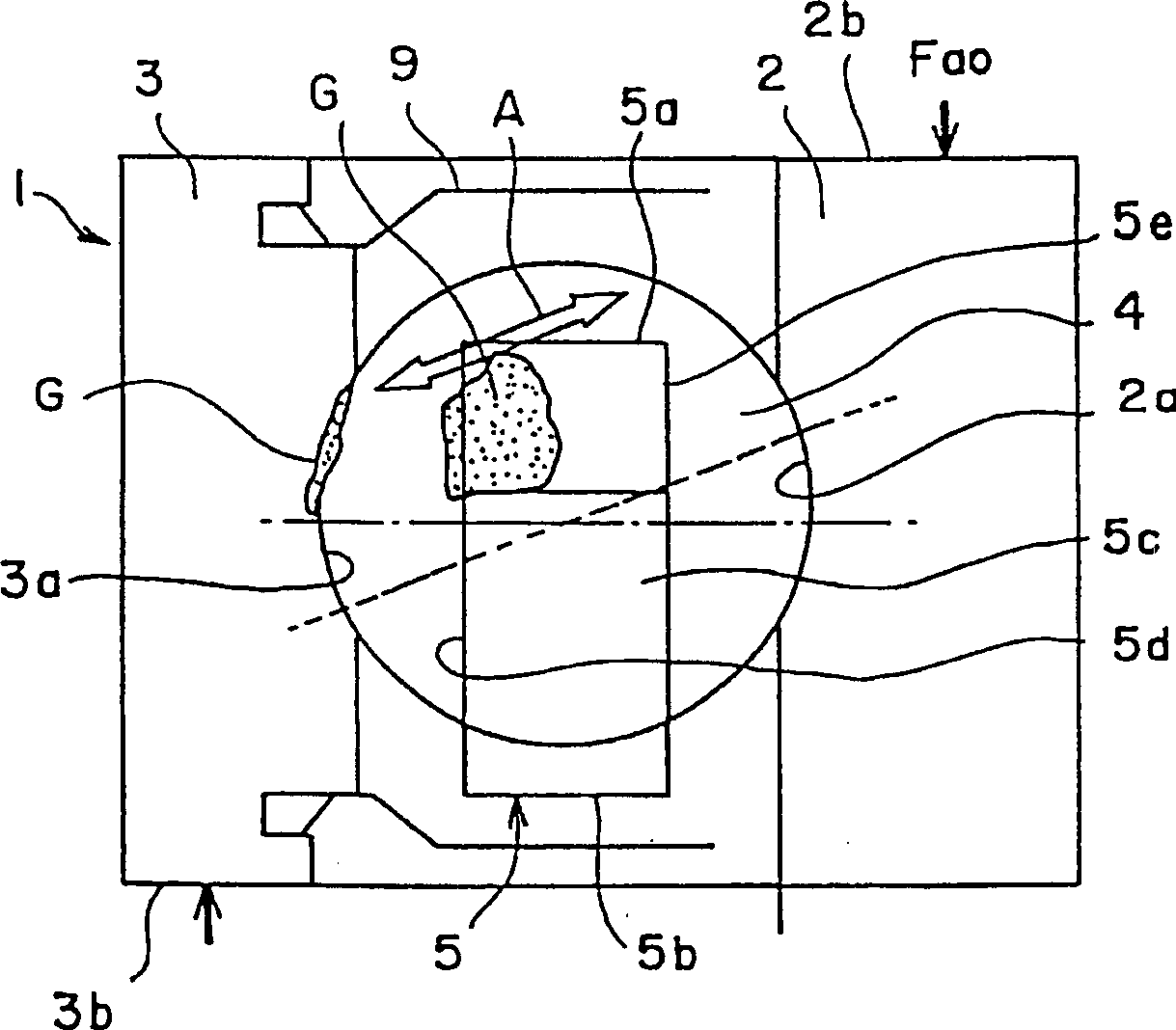

[0125] here, figure 1 A first embodiment of a bearing arrangement according to the invention is shown. This bearing device includes two rolling bearings 1 and 1, wherein the two rolling bearings 1 and 1 are respectively fixed to the outer circumference of the shaft 6 with the inner rings 2 and 2 of the two rolling bearings and the preload (axial load) is applied to the two rolling bearings combined in the above manner. Also, in this embodiment, a description of the structure will be given using two bearings as a pair, however, the present invention is not limited to such a combination of two bearings.

[0126] The rolling bearing 1 is a ball bearing, which includes an inner ring having an inner raceway 2a formed on its outer periphery, an outer ring having an outer raceway 3a formed on its outer periphery, a plurality of rolling rollers inserted between the inner raceway 2a and the outer raceway 3a elements 4, and crowned cages 5 for holding the rolling elements 4 at regula...

no. 2 example

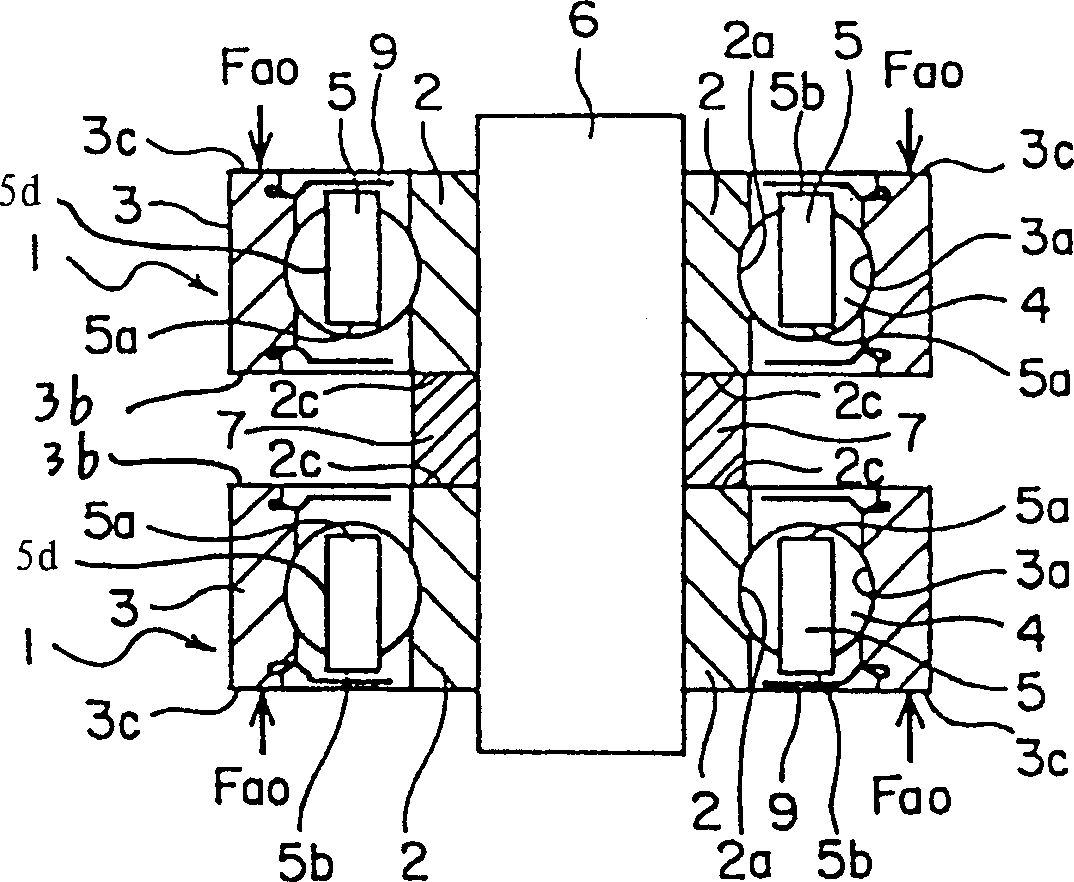

[0134] Now, image 3 A second embodiment of a bearing arrangement according to the invention is shown.

[0135] This embodiment differs from the first embodiment in that the sheath opening sides 5a and 5a of the cages 5 and 5 of the two rolling bearings 1 and 1 are arranged opposite to each other and in that the preload is applied not only to the On the end faces 2c and 2c of the inner rings 2 and 2 on the side 5a and 5a, and on the end faces 3c and 3c of the outer rings 3 and 3 on the opposite side 5b and 5b of the cage sheath opening, therefore, the inner ring 2. The outer ring 3 , the rolling elements 4 , and the cage 5 are not limited to any particular one, but any structure may be adopted, and therefore, by adopting the first embodiment, a detailed description thereof is omitted here.

[0136] According to this embodiment, between the inner rings 2 and 2 of the rolling bearings 1 and 1, a spacer 7 is inserted, and the preload Fao is applied to the outer rings 3 and 3 fro...

no. 3 example

[0140] Now, Figure 4 A fourth embodiment of a bearing arrangement according to the invention is shown.

[0141] The bearing device according to the present embodiment includes a housing 10 whose inner periphery is formed with double rows of raceways 10a and 10a; One raceway 10a is opposed; a separately formed inner ring 2 which can be fixed to another part of the outer circumference of the shaft 6 so that its raceway 2a is opposed to the other raceway 10a of the housing 10; and a plurality of rolling elements (Balls) 4... and 4..., which are installed between one raceway 10a of the housing 10 and the raceway 6a of the shaft 6 and the other raceway 10a of the housing 10 and Between the raceways 2a of the inner ring 2.

[0142] And in this example, if Figure 4 As shown, the left side of the shaft 6 is fixed, while the right side end face 2b of the separately formed inner ring 2 on the right side is pushed, thereby applying a preload Fao. Therefore, this type of preload pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com