Location loading material testing machine

A material testing machine and loading system technology, applied in the direction of analyzing materials, applying stable tension/pressure to test material strength, measuring devices, etc., can solve the problems of large floor area, expensive equipment use and maintenance costs, etc., to achieve occupancy The effect of small space, simple and clear equipment principle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

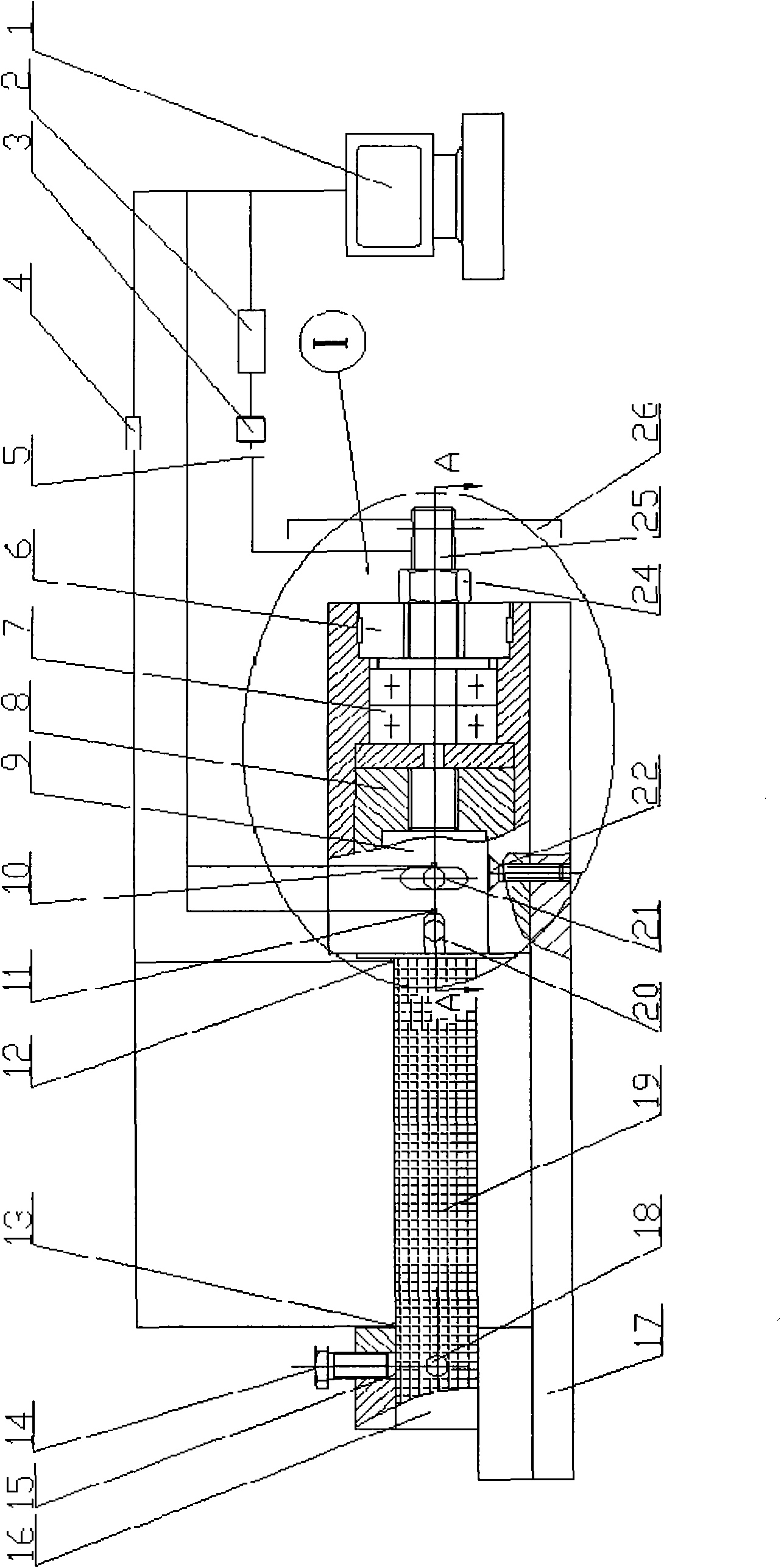

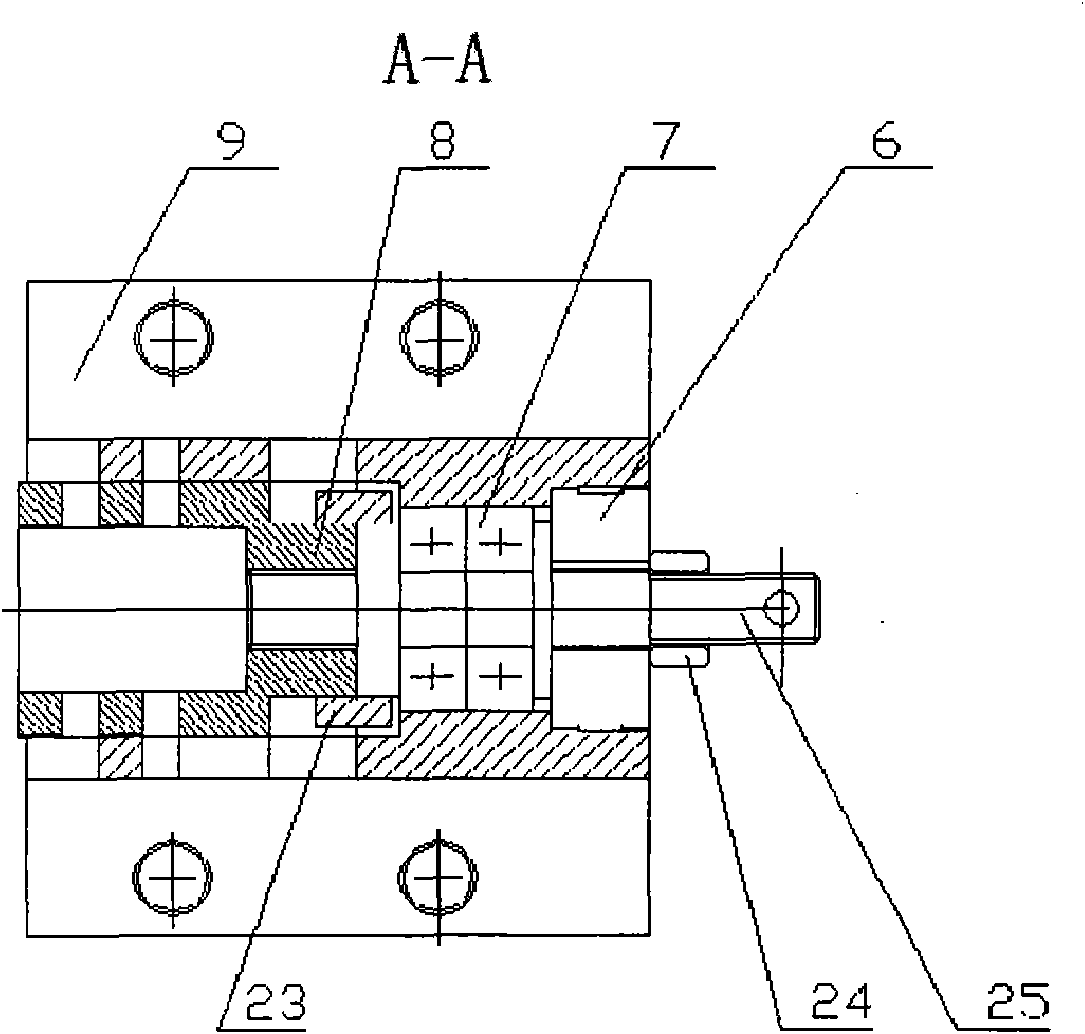

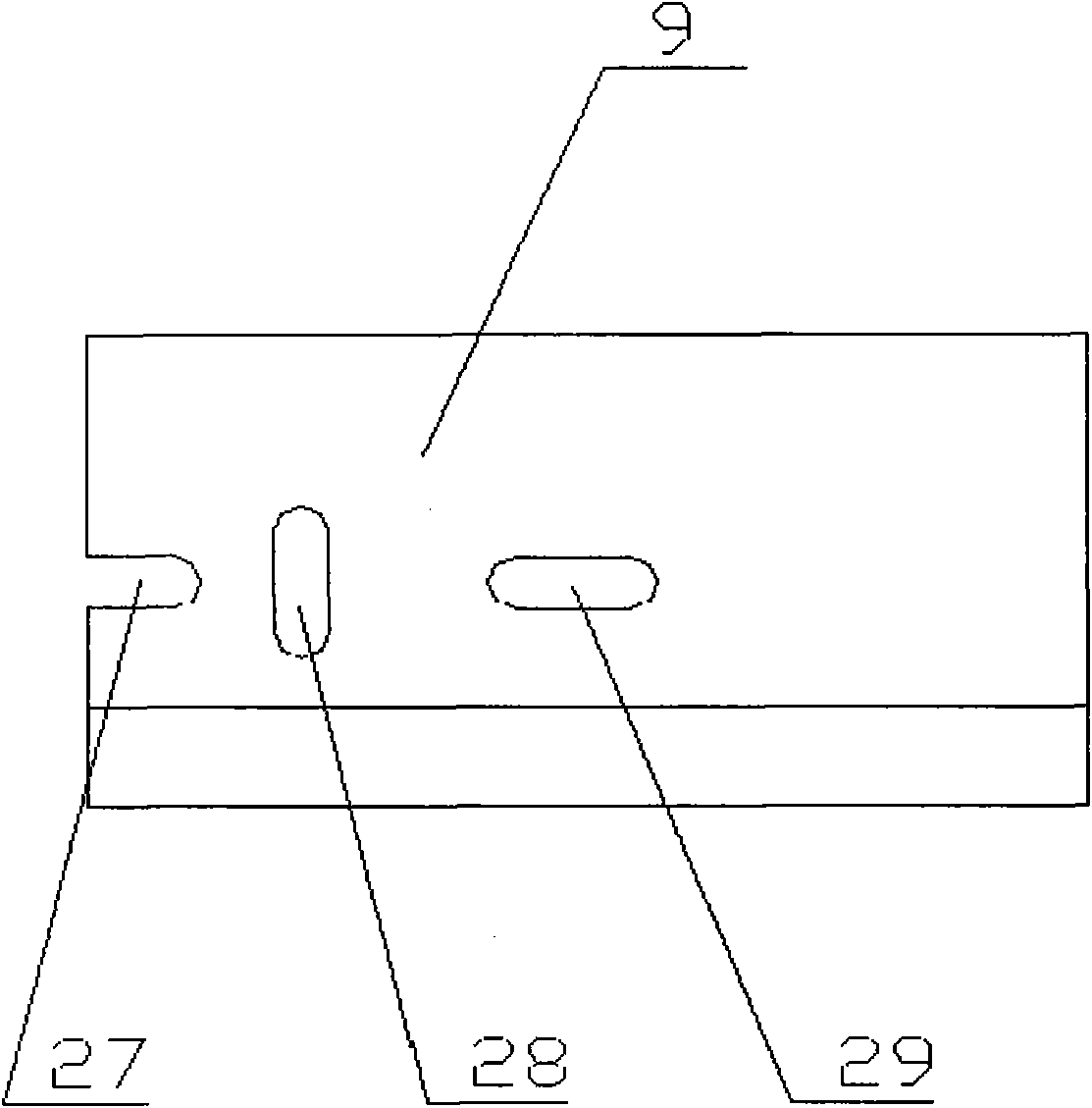

[0023] Said invention consists of figure 1 The overall structure diagram of the material testing machine, figure 2 Positioning and loading system (section top view), image 3 Locate the loading base (appearance front view), Figure 4 Front view of the flanged shaft and Figure 5 Flange shaft side view composition. The loading method is divided into automatic control loading and manual control loading.

[0024] The specific function realization mode of the patented material testing machine of the present invention is as follows:

[0025] 1. Control system: during automatic loading, input the required realization parameter value on the corresponding program interface of the industrial computer 1, and then the software sends a control signal to the motion control card 2, and the motion control card 2 drives the stepping motor after processing the control information 3 rotates, the stepper motor 3 drives the flange shaft 25 to rotate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com