Method for threading in a thread

A threading and yarn technology, applied in the threading field, can solve the problems of unwinding performance influence, unfavorable complexity, etc., and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

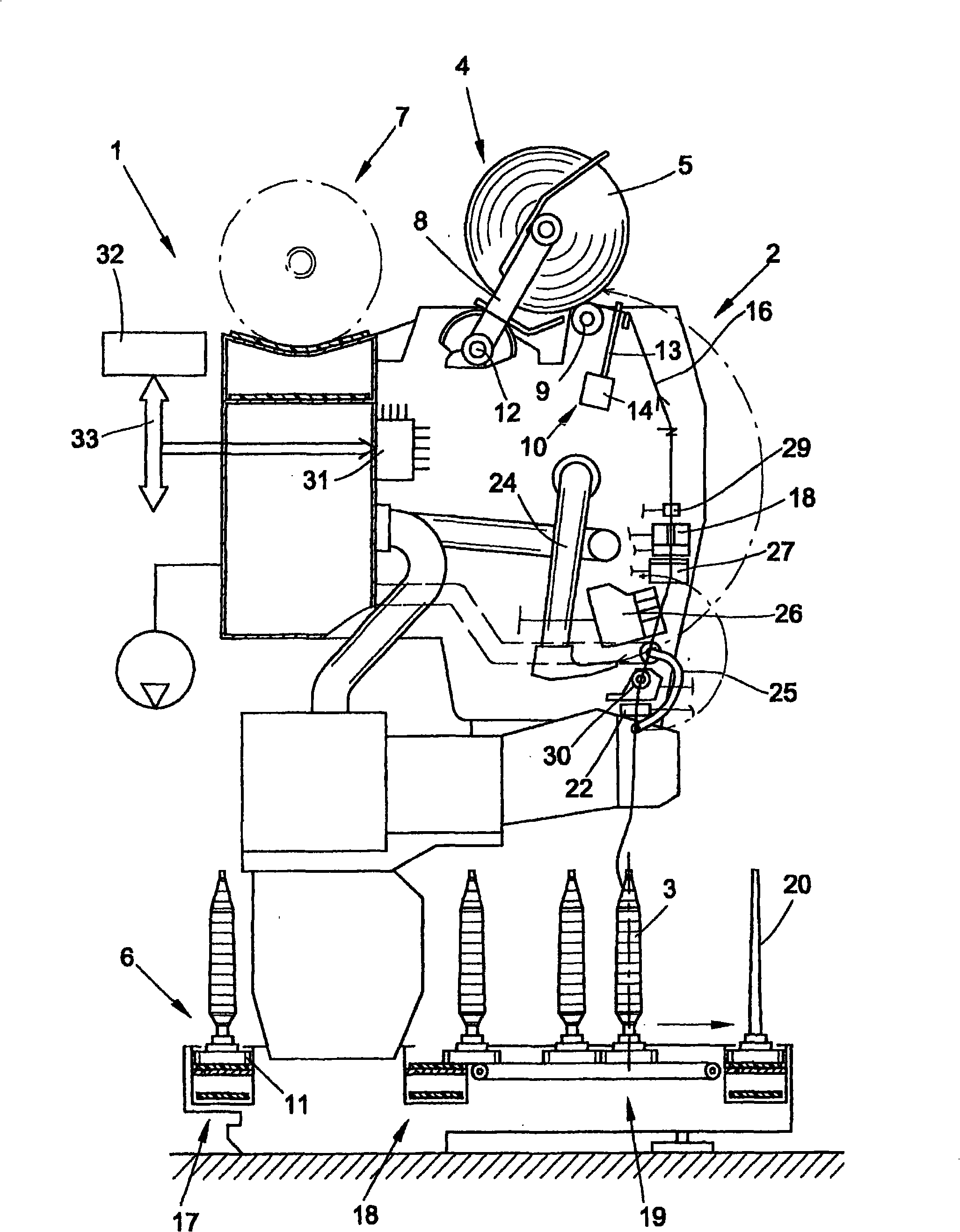

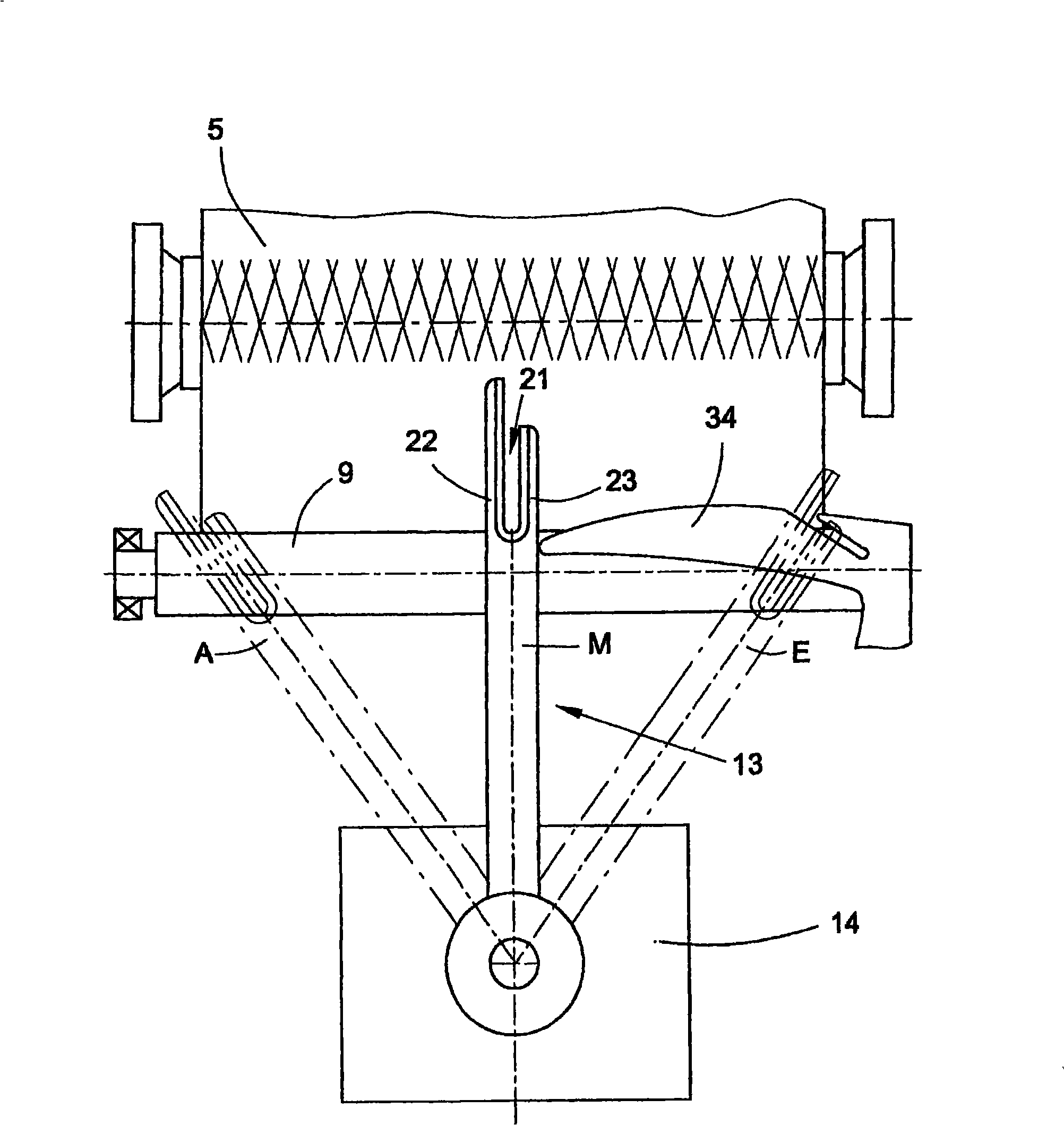

[0023] figure 1 A side view of station 2 of a textile machine for producing cross-wound bobbins is schematically shown. In this example, the textile machine is a so-called automatic cross-winding textile machine 1 . Since this type of textile machine is known, it will not be described in detail. On the station 2 of the automatic cross-winding textile machine 1, the worsted bobbins 3 produced on the spinning frame are rewound so as to form large volume of cross-wound bobbins 5 .

[0024] As soon as they are completed, the cross-wound bobbins 5 are transferred in the longitudinal direction of the machine to the cross-wound bobbin conveyor 7 by means of an automatically operating service unit (not shown), preferably a so-called cross-wound bobbin changer, and conveyed to the bobbin loading station or similar at the end of the machine. Automatic cross-winding textile machines 1 of this type usually also have a supply device in the form of a bobbin and bobbin delivery system 6 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com