Construction method using long-distance preset concealed pipe to sleeve lead

A construction method and a technology of pre-piercing lead wires, which are applied in the direction of cable installation, cable laying equipment, cable installation devices, etc., can solve the problems of difficult construction, high cost, high price, etc., and achieve reliable threading, low construction cost, and easy construction The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

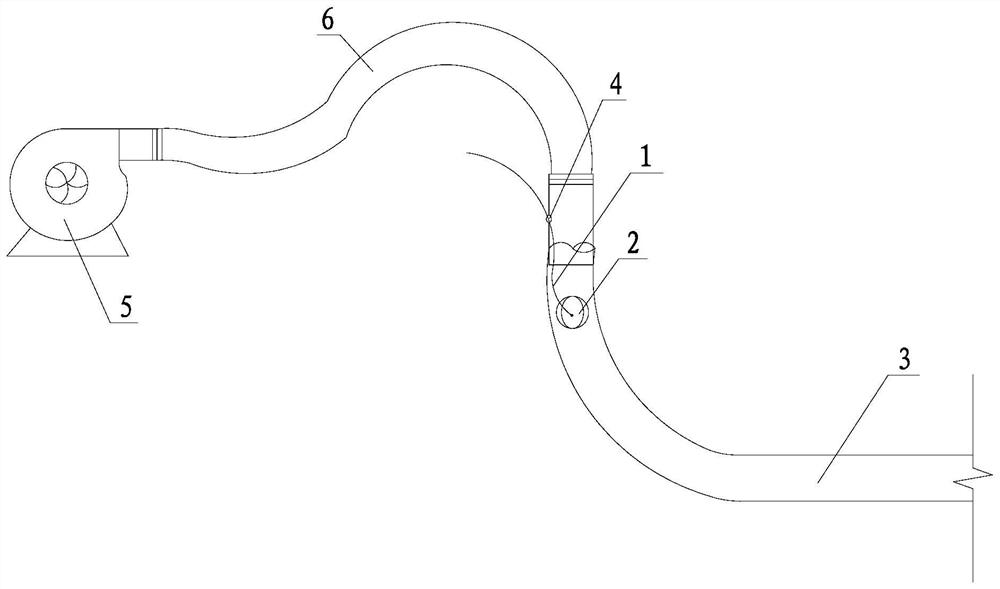

[0025] The technical solution adopted in this application to solve technical problems is:

[0026] 1. The construction method of this application mainly includes a lightweight plastic ball hollow ball one grade smaller than the diameter of the embedded pipe, a high-strength flexible lead wire, a blower, and an air supply sleeve;

[0027] 2. Pass the high-strength flexible lead wire through the hollow ball of the light plastic ball, connect it with the sphere, and put the connected sphere into a section of the pipe to be threaded;

[0028] 3. Connect the air supply pipe to the wire pipe at the end of the ball, and reserve a small hole for the lead wire to enter;

[0029] 4. Connect the blower to the air supply pipe, start the blower, let the wind drive the plastic ball to move along the pre-buried pipe, and follow up to loosen the lead wire. After the plastic ball is blown out from the other section of the embedded pipe, the lead wire passes through the embedded pipe smoothly;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com