Roving machine with reel change mechanism

A technology of roving frame and bobbin rail, which is applied in textile and papermaking, thin material processing, conveying filamentous materials, etc. bootstrap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

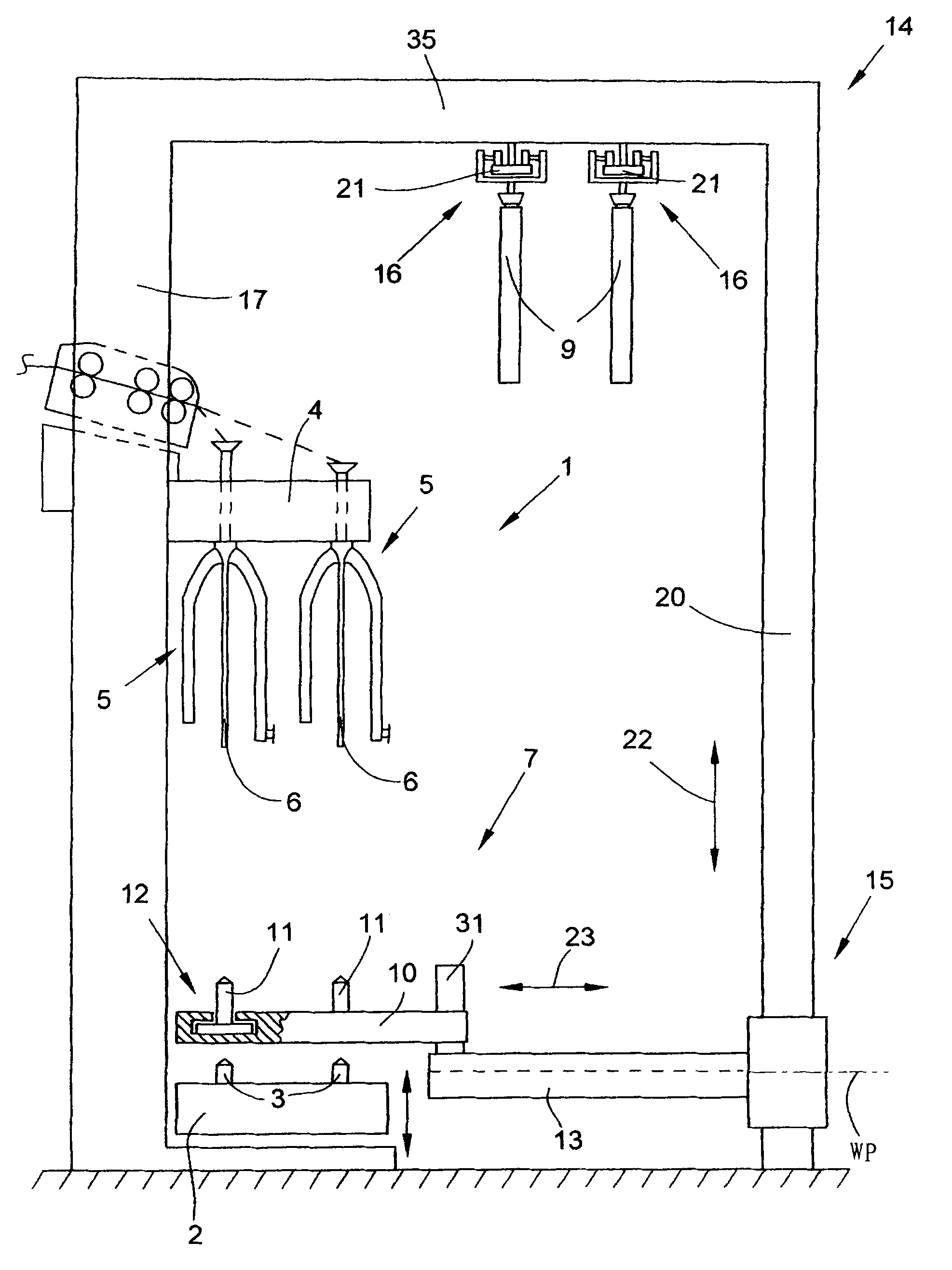

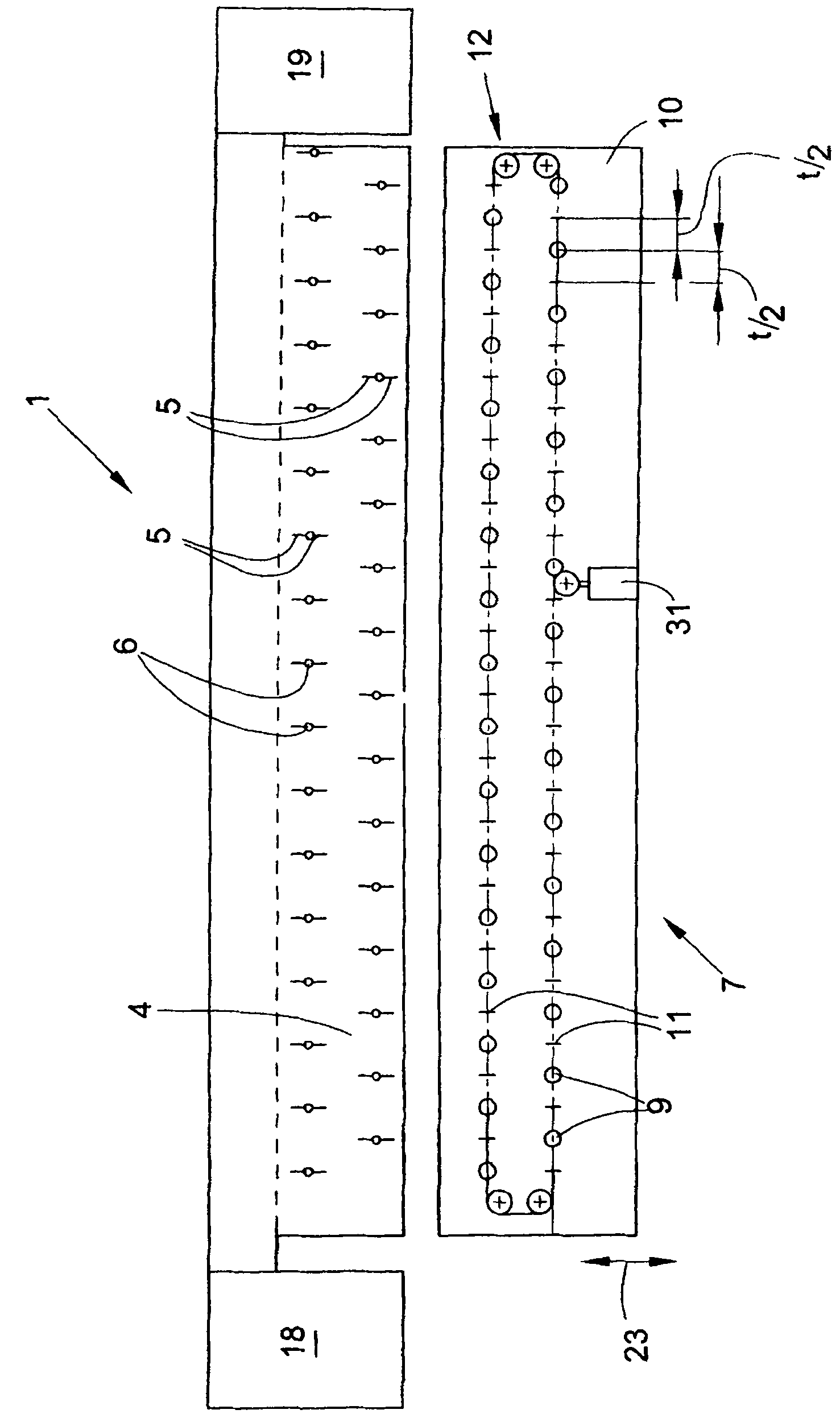

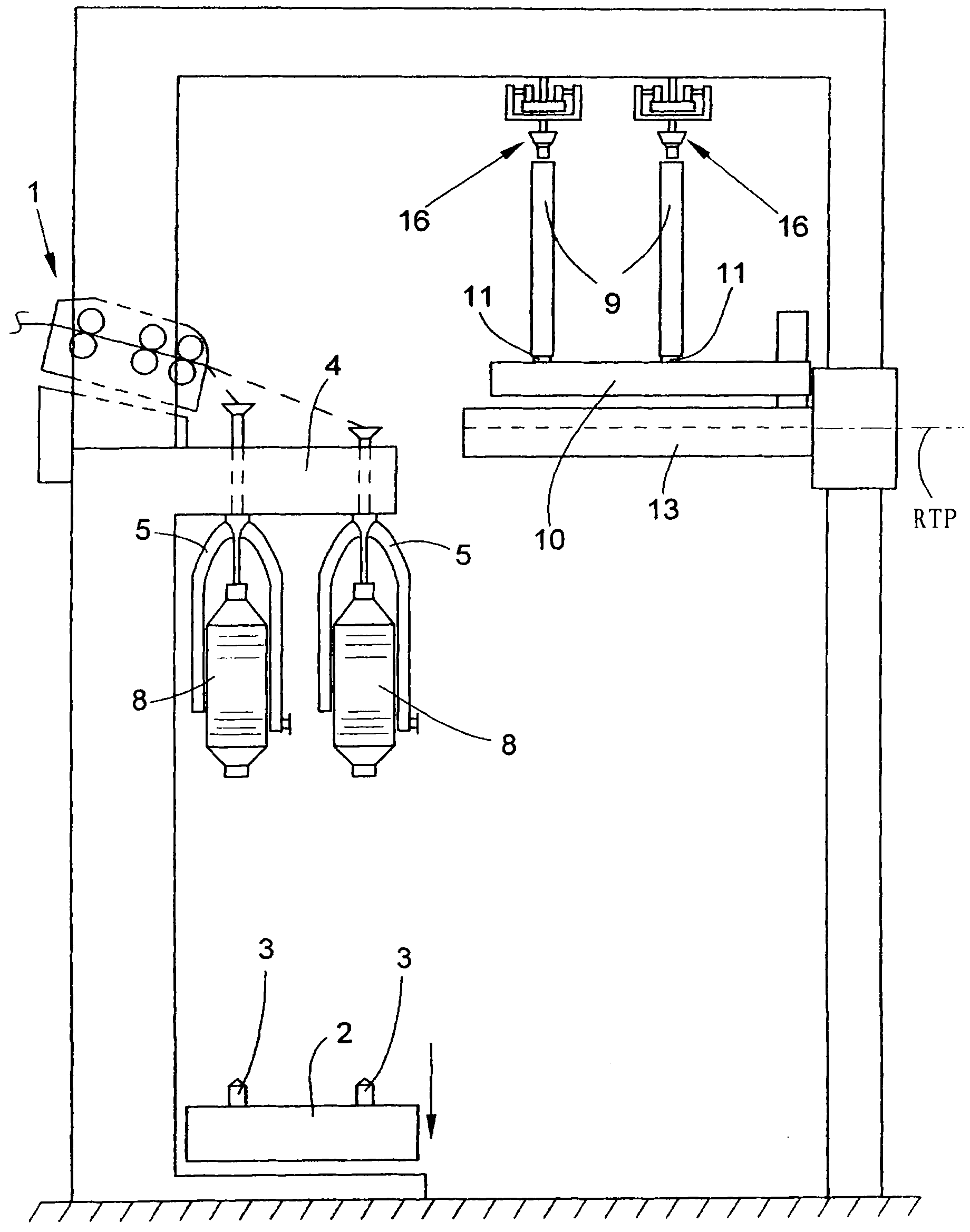

[0024] figure 1 A roving frame 1 is shown in , which has a bobbin rail 2 mounted displaceably in the vertical direction and a fixedly arranged flyer rail 4 between end frames 18 , 19 . The flyers 5 of the flyer rail 4 each have a relatively long central spindle 6 , while the bobbin holders 3 arranged in the region of the bobbin rail 2 are relatively short. A frame structure 14 spans the roving frame 1 , on which the can changer 7 according to the invention is guided in a vertically displaceable manner. as from figure 1 It can be seen that the frame structure 14 is configured as a gantry structure, in other words, the frame structure 14 has a rear support column 17, a front support column 20 and a horizontal frame 35, in the region of the horizontal frame 35 there are provided for Rail member 21 of suspended carrier 16 . The base element 13 of the can changing mechanism 7 is hinged on at least two front support columns 20 , for example via slide guides 15 , so that the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com