Workstation of a textile machine

A technology of textile machines and workstations, which is applied in the direction of thin material handling, delivery of filamentous materials, transportation and packaging, etc., which can solve the problem of large air consumption and achieve the effect of reliable guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

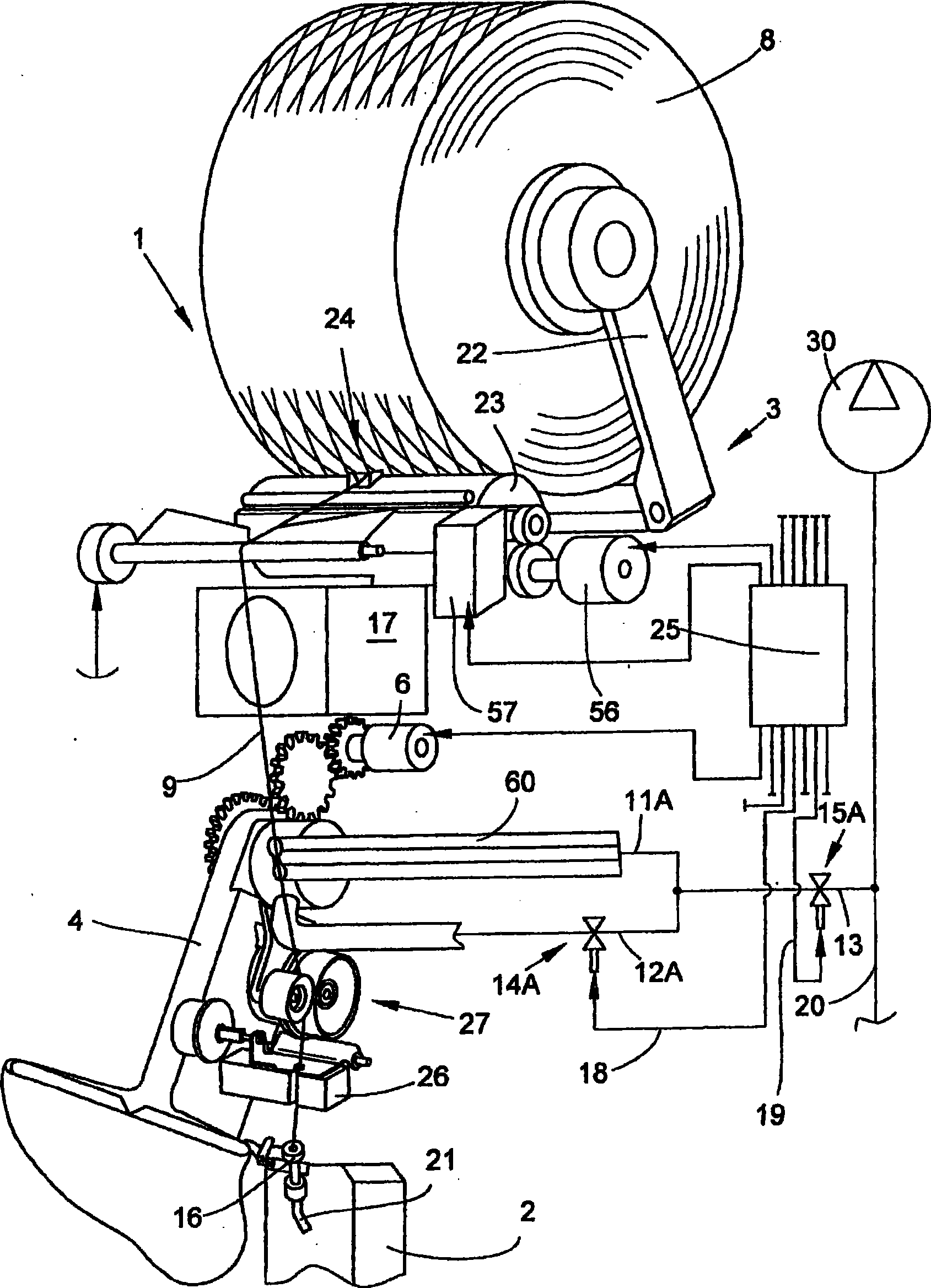

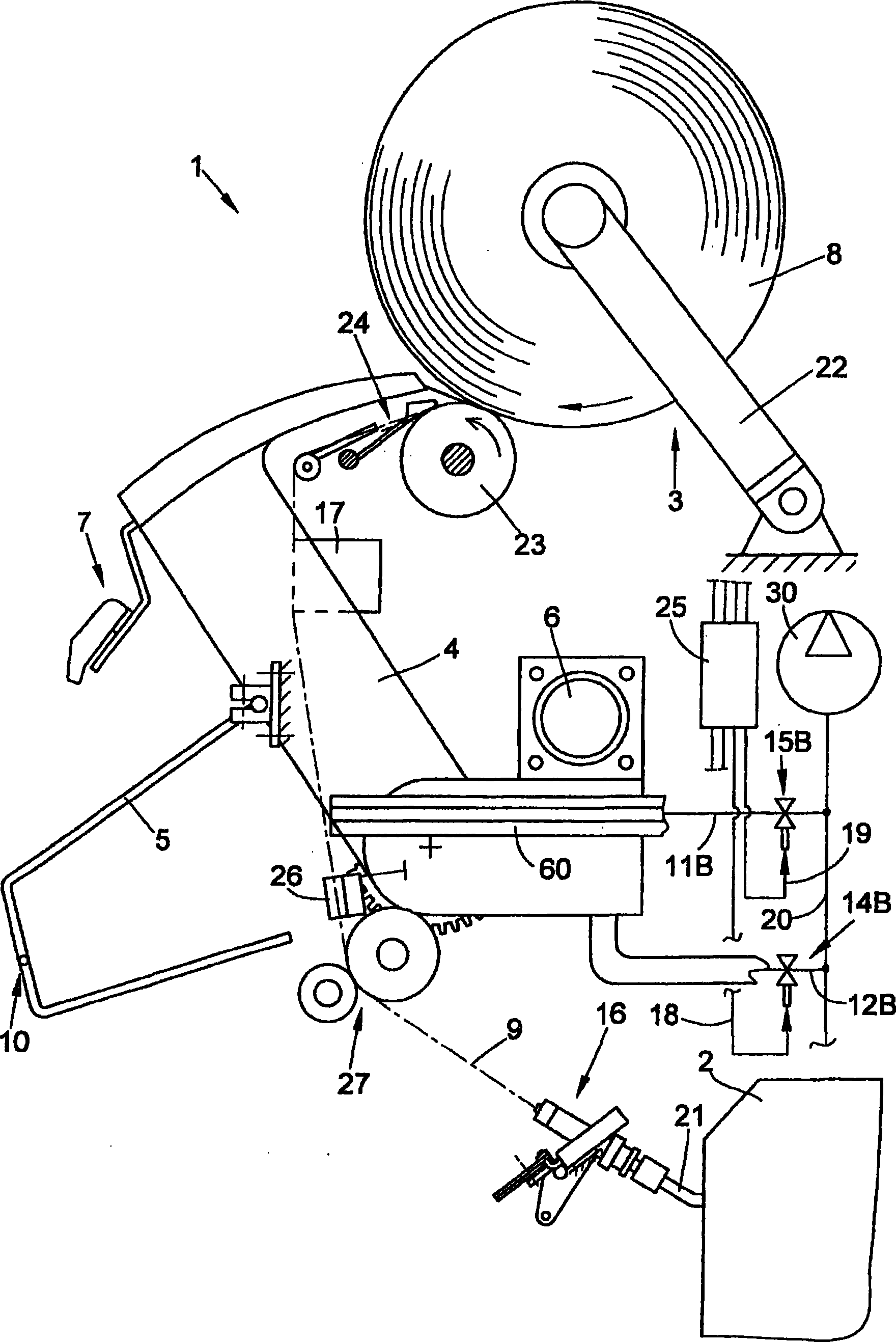

[0018] figure 1 A fully equipped station 1 of an open-end rotor spinning machine is shown in perspective, in which the first embodiment according to the invention is used. As is known (and is therefore only shown schematically), such a station 1 essentially comprises an open-end spinning device 2 and a winding device 3 .

[0019] The splicing mechanism 16 is arranged in the region of the so-called yarn take-off tube 21 of the open-end spinning device 2 , which is obtained from the cross-wound yarn by the suction nozzle 4 after the yarn is broken or after a controlled cut by the yarn clearer. The yarn 9 returned by the bobbin 8 and the end of the thread is prepared for spinning-in.

[0020] In addition, a yarn withdrawal device 27 is provided, which not only takes care of pulling the textile yarn 9 from the open-end spinning device 2 during normal spinning operation, but also takes care of feeding the ready yarn 9 in a predetermined amount during spinning-in. The way is sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com