Emptying cartridge, method for emptying chamfers filled with rod-shaped objects and device for bringing together mass flows, in particular for an emptying cartridge

A product and material flow technology, which is applied in the field of at least two vertical and rod-shaped product collection areas that control the product material flow in the emptying box, achieves the effects of simple structure, easy implementation and improved functional reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

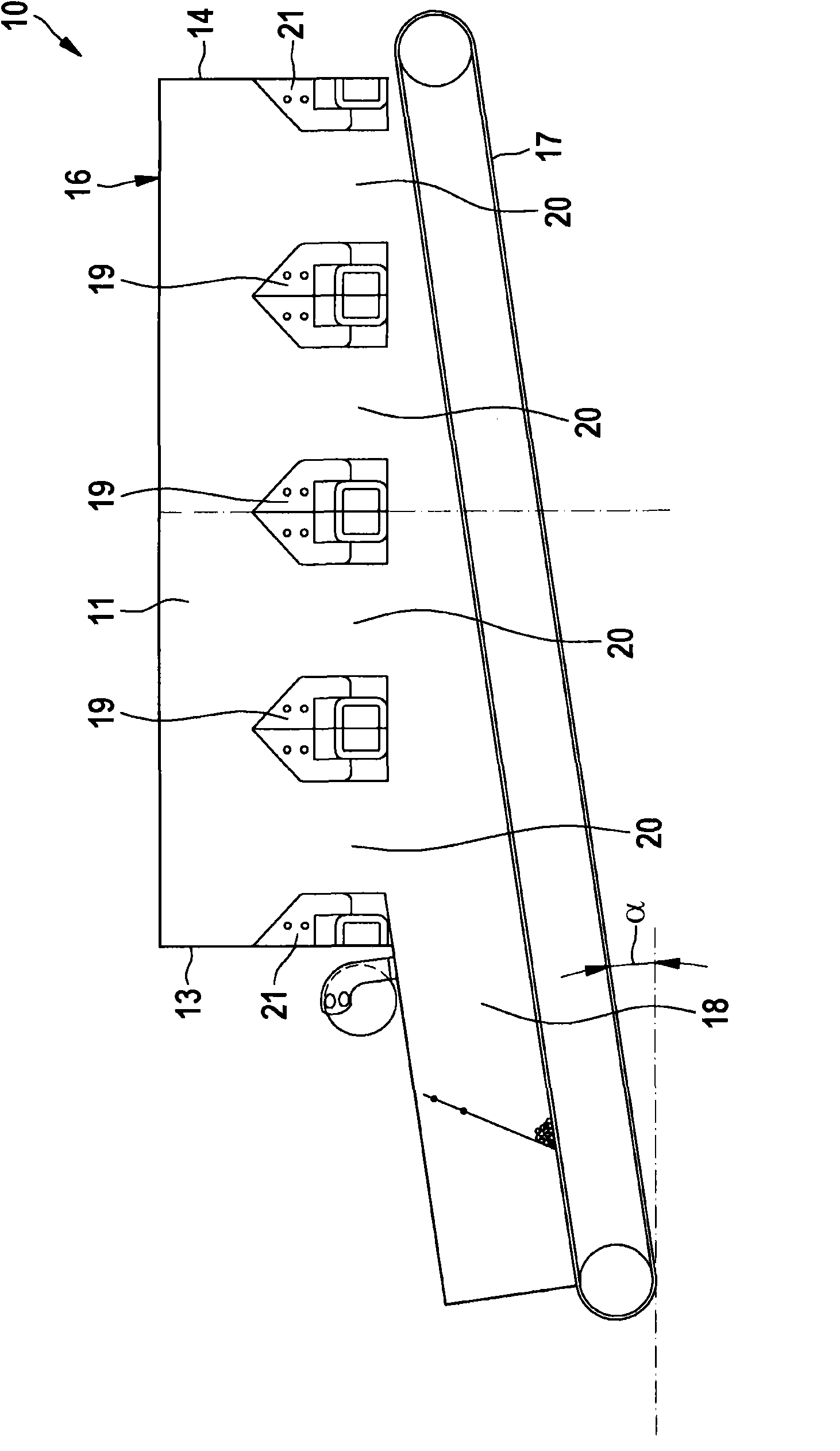

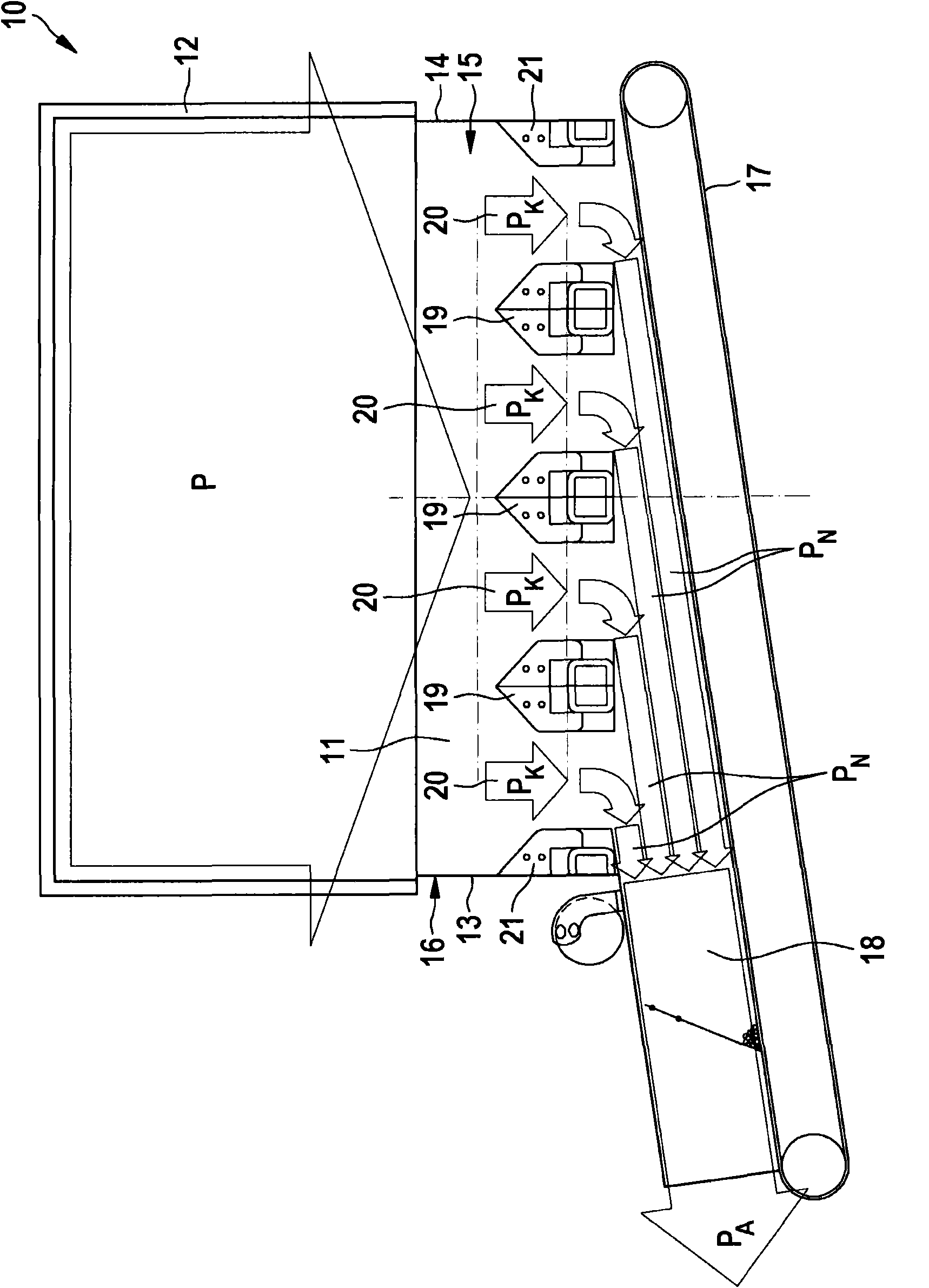

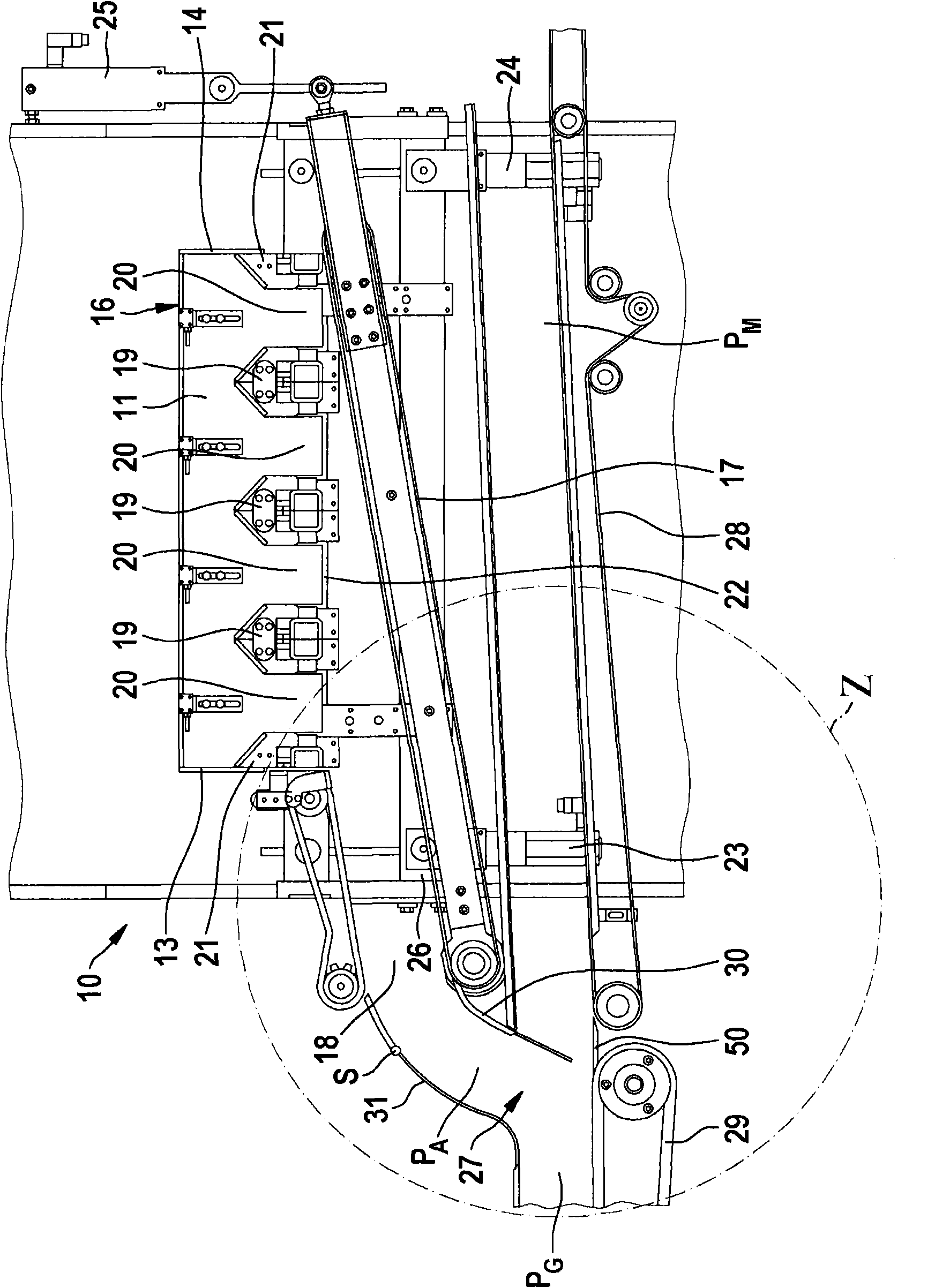

[0020] The emptying box shown in the picture is used to empty containers on the hopper station filled with rod-shaped products, but it can also be used as a stand-alone unit.

[0021] The first embodiment of the emptying box 10 comprises a collection area 11 for flowing product from a container 12, such as a hopper or trough hopper. The collection area 11 is bounded on all sides. This means that the collection area 11 is bounded by two side walls 13 , 14 , a front wall 15 (omitted from the figures for greater clarity) and a rear wall 16 . In the upward direction of the container 12 , the collection area is designed to be open, but can optionally be closed with a suitable closure element. The collection area 11 is bounded downwards by a transfer element 17 . The conveying element 17 is spaced apart from the collection area 11, so that the conveying element 17 forms a channel 18 in which the product is conveyed. Inside the collection zone 11 at least one flow control element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com