Vane-type compressor

A compressor and vane-type technology, which is applied in the field of compressors, can solve the problems of increasing the number of parts and cost, and achieve the effect of preventing the increase of the number of parts, preventing the increase of cost, and reliable reciprocating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

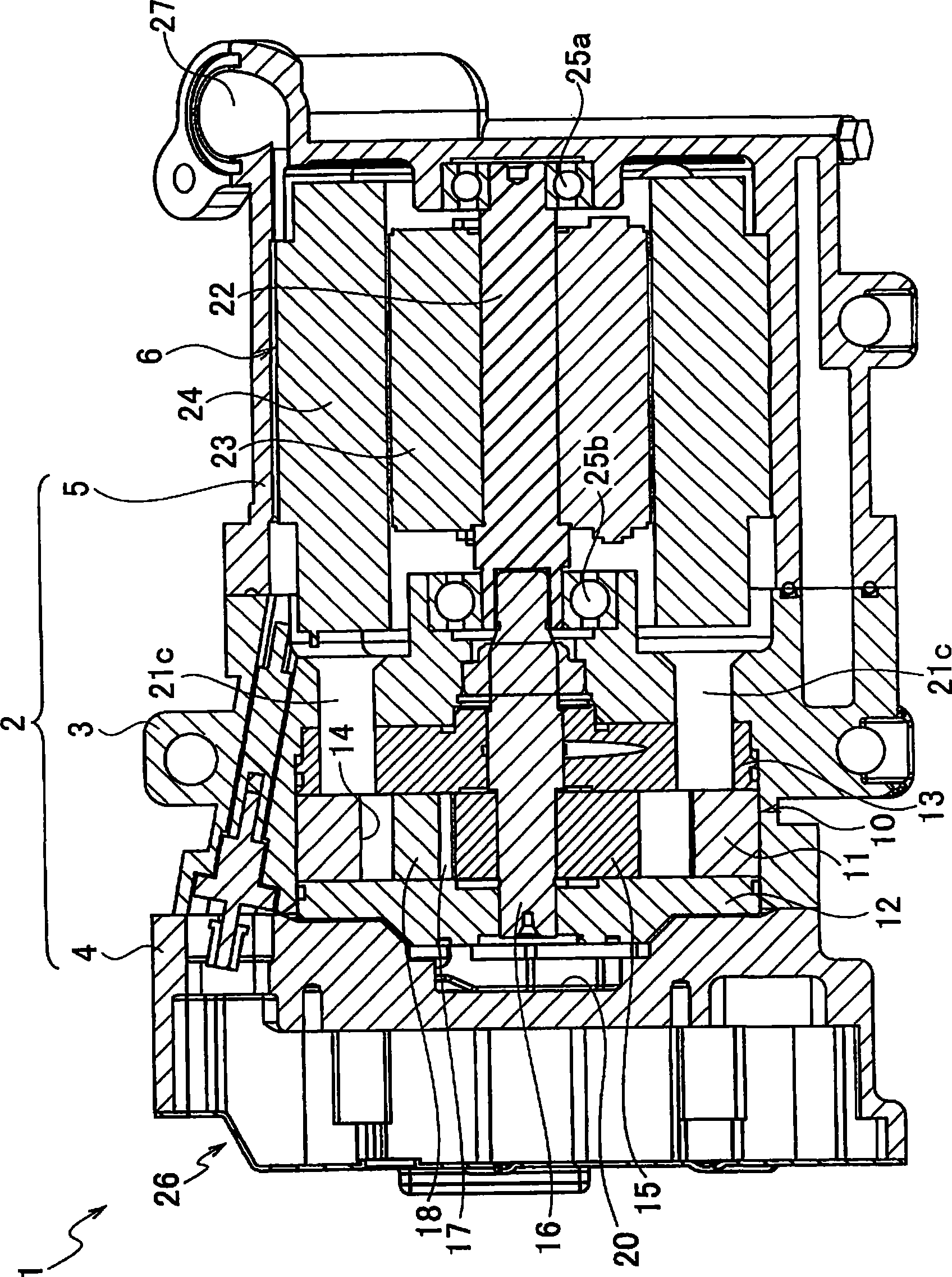

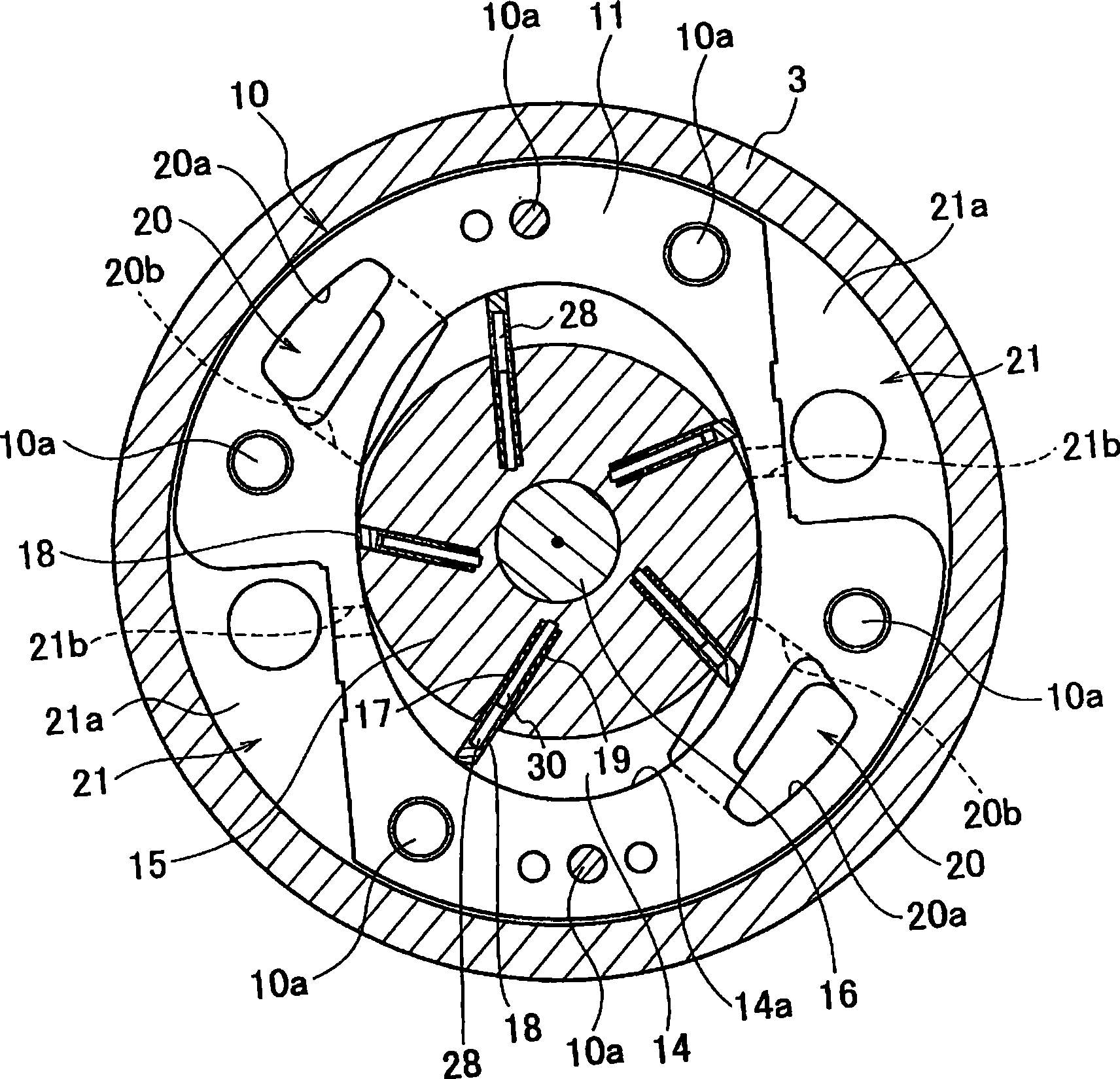

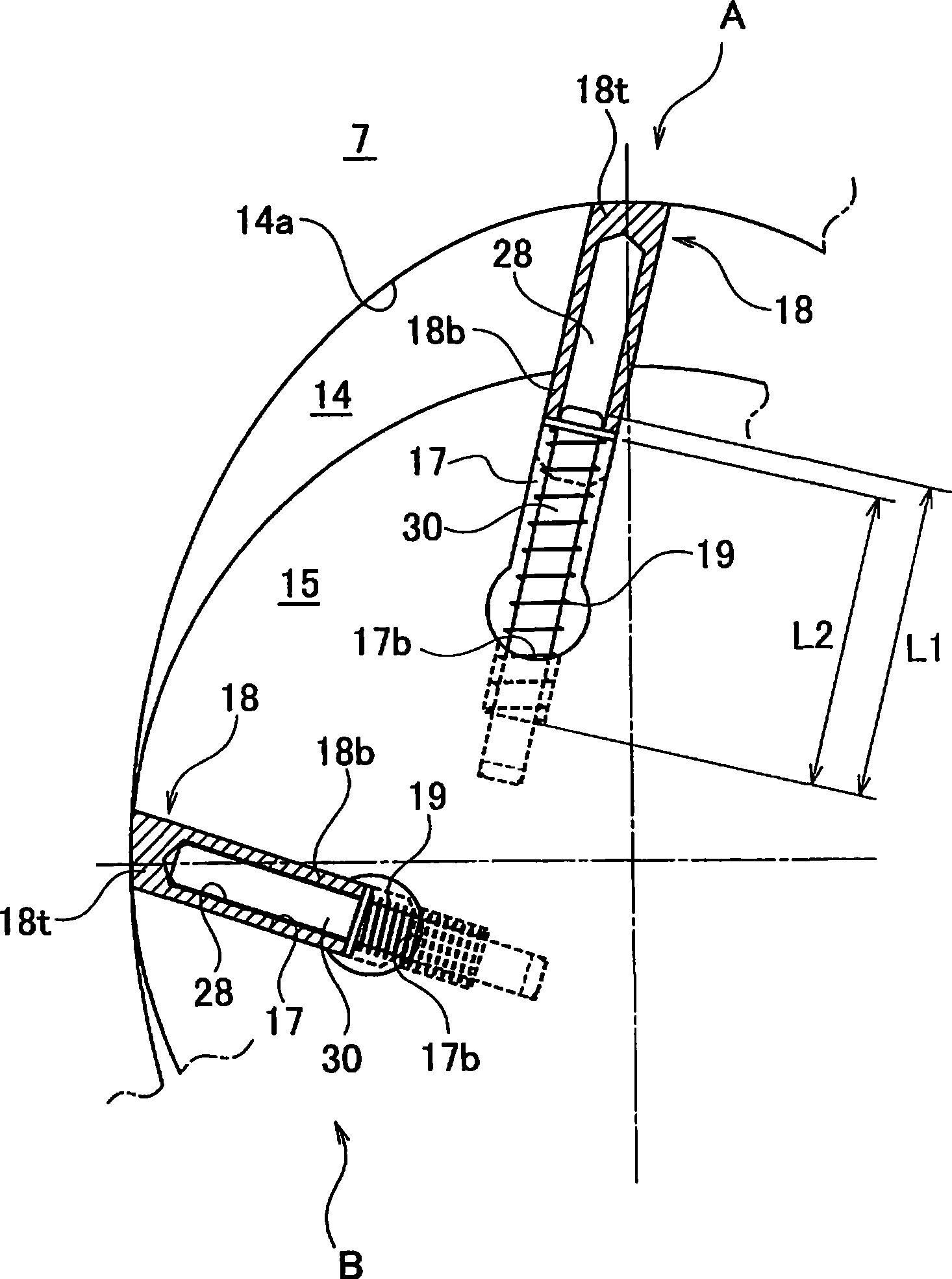

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, refer to Figure 1 ~ Figure 3 The first embodiment will be described.

[0055] Such as figure 1 As shown, the compressor 1 has a housing 2 . The housing 2 is composed of a substantially cylindrical compressor housing 3 , a front housing 4 disposed at one open end of the compressor housing 3 , and a motor housing 5 disposed at the other open end of the compressor housing 3 . The compressor casing 3, the front casing 4, and the motor casing 5 are all made of aluminum alloy.

[0056] The compression unit 10 is accommodated in the compressor housing 3 . The compression unit 10 includes a cylinder block 11 , a front cylinder block 12 and a rear cylinder block 13 respectively arranged on two sides of the cylinder block 11 . These cylinder blocks 11, 12, 13 use bolts 10a (refer to figure 2 ) are fastened together. Compression chambers 14 are formed in the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com