Conduit

A wire protection tube and wire harness technology, applied in the field of wire protection tubes, can solve problems such as broken wires and inability to ensure electrical connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] One embodiment of the present invention will be described in detail with reference to the following drawings.

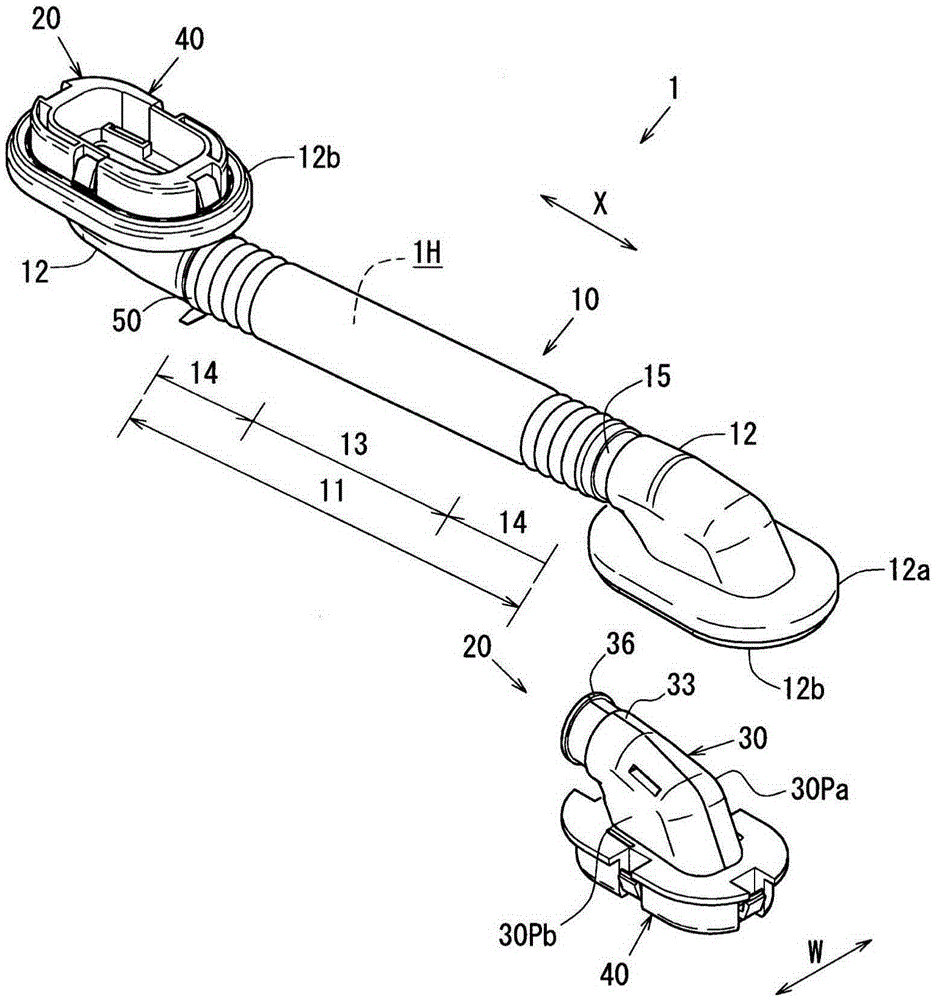

[0050] Such as Figure 1 to Figure 8 As shown, the grommet 1 of this embodiment is composed of a tubular grommet main body 10 and internal components 20 provided at both ends of the grommet main body 10, wherein the tubular grommet main body 10 has a The insertion hole 1H through which the wire harness WH is inserted.

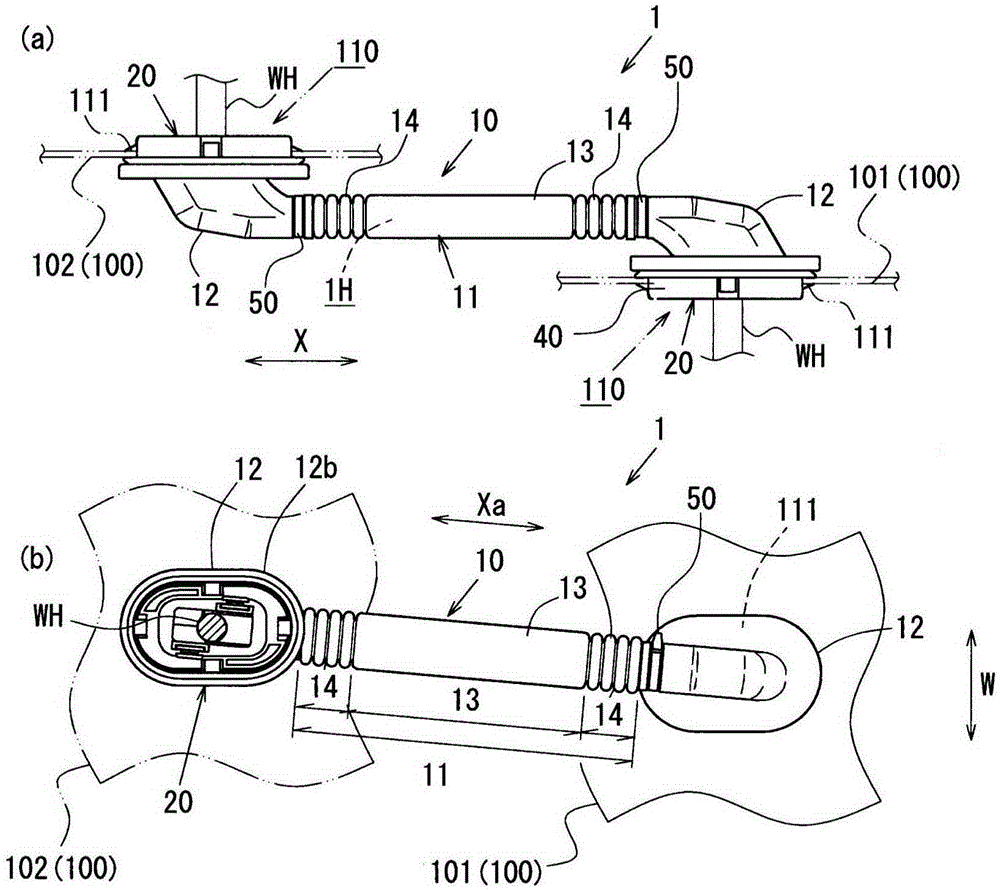

[0051] also, figure 1 An exploded perspective view of the grommet 1 showing a state where the inner member 20 on one end side of the grommet main body 10 is separated, figure 2 (a) shows a front view of the grommet 1 with both ends attached to the partition wall 100, figure 2 (b) is a top view of the grommet 1 in this state.

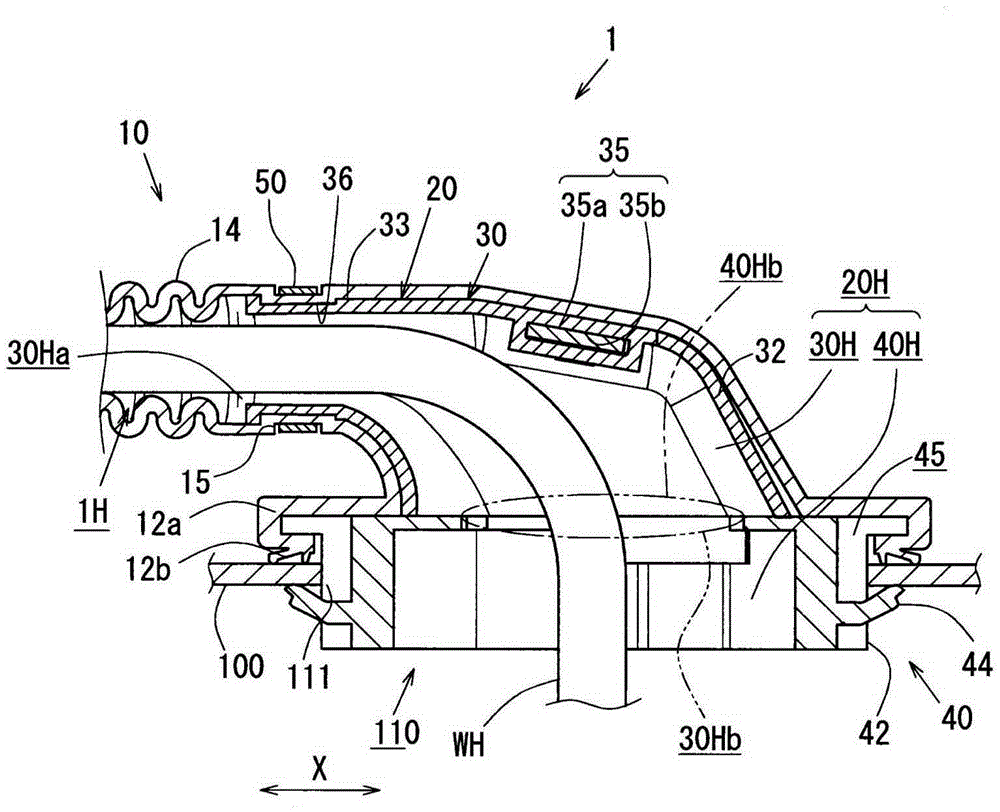

[0052] image 3 An enlarged longitudinal sectional view showing an intermediate portion in the width direction W at an end portion of the grommet 1 in a used state, Figure 4 It shows the perspective view which lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com