Tensioning or guide rail having a continuous recessed sliding body

A technology for guiding rails and sliding bodies, applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of transmission chain manufacturing tolerances, elongation, etc., and achieve the effect of reducing noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

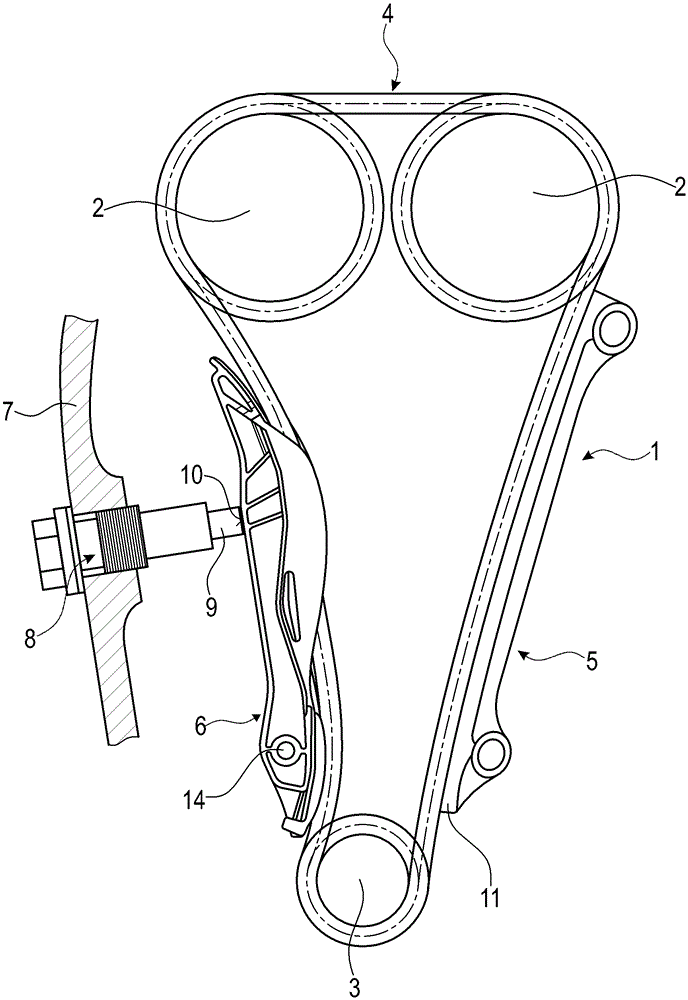

[0017] exist figure 1 A timing chain drive 1 for an internal combustion engine, shown schematically in , comprises two upper camshaft sprockets 2, a lower crankshaft sprocket 3, an endless drive or timing chain 4 wound around said sprockets, for timing A conventional guide rail 5 that guides the timing chain 4 in the tensioned span of the timing chain drive 1 and a pivotally arranged tensioner that presses against the timing chain 4 in the slack span of the timing chain drive 1 Track 6. The tensioning rail 6 is pressed against the timing chain 4 by a tensioning device 8 provided in the engine hood 7 . The tensioning device 8 is here preferably configured as a hydraulically operated chain tensioner, which is connected to the engine oil hydraulics, so that the tensioning piston 9 of the tensioning device 8 presses against the pivotally arranged tensioning rail 6 Press area 10. The conventionally designed guide rail 5 rests with its sliding contact surface of the sliding body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com