Measuring instrument for flow resistance of porous sound absorption material

A porous sound absorption and material flow technology, applied in the direction of measuring devices, instruments, fluid dynamics tests, etc., can solve the problem of lack of reliable support and positioning structure for sample materials, inaccurate measurement results, poor reliability, reliability and economy, etc. problem, to achieve the effect of good reliability and economy, convenient displacement adjustment operation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

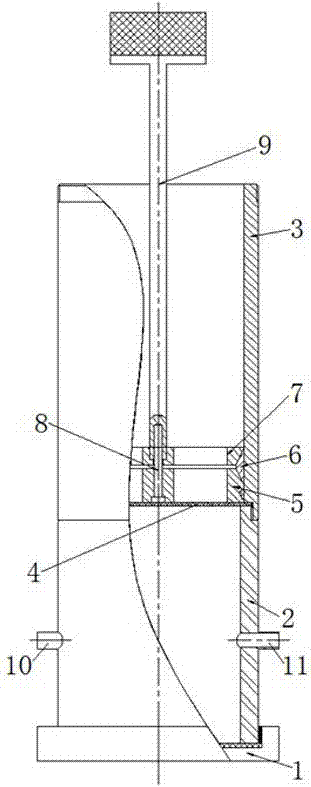

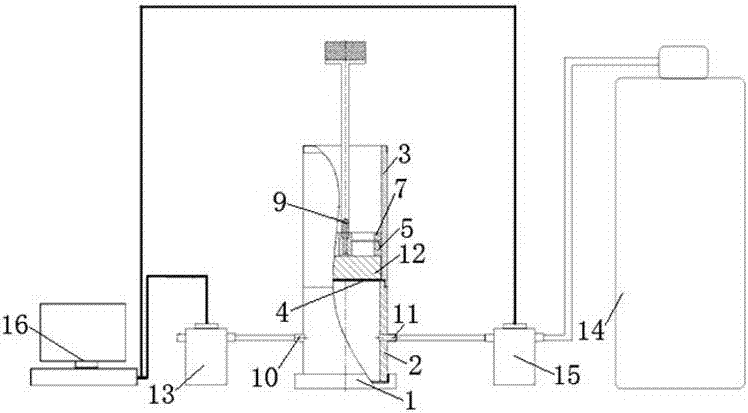

[0023] see figure 1 with figure 2 As shown, the present invention includes a sample cartridge, air pump assembly 14 and computer 16 .

[0024] Wherein, the sample cylinder is a blind hole structure with one end closed and the other open. Specifically, the sample cylinder is mainly composed of the front section 3 of the sample cylinder, the rear section 2 of the sample cylinder and the base 1 arranged in sequence in the axial direction. The front section 3 of the sample cylinder and the rear section 2 of the sample cylinder are respectively cylindrical structures with open ends, and the inner diameter of the rear section 2 of the sample cylinder is required to be smaller than the inner diameter of the front section 3 of the sample cylinder, and the range of the difference between the two inner diameters is 2 ~10mm, such as 3mm, 5mm, 7mm or 10mm, etc., the preferred range is 5-7mm; the outer wall of the front end of the rear section 2 of the sample cylinder has a threaded joi...

Embodiment 2

[0031] The invention includes a sample cartridge, an air pump assembly and a computer.

[0032] Wherein, the sample cylinder is a blind hole structure with one end closed and the other open. Specifically, the sample cylinder is mainly composed of a cylinder body and a base. The base is a blind hole structure whose inner diameter matches the outer diameter of the rear end of the cylinder. The inner wall of the front end of the base has a threaded joint; the outer wall of the rear end of the cylinder has a threaded joint. The rear ends are axially connected and combined through the corresponding and matching threaded joints, and a sealing gasket is provided between the inner bottom surface of the base and the rear end of the cylinder, so it can be seen that the end of the sample cylinder has a closed structure It is mainly composed of the corresponding end of the sample cylinder and the base blocked at the corresponding end of the sample cylinder. The inner wall of the middle ...

Embodiment 3

[0039] The other content of this embodiment is the same as that of Embodiment 1 or 2, except that the thickness measuring instrument is integrated on the inner surface of the rear tapered ring, and the signal line of the thickness measuring instrument is drawn out from the gas flow channel of the rear tapered ring .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com