Automatic winder

An automatic winder and bobbin technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problem of inability to quickly perform the wiring process using the connector, and achieves omitting the guiding parts, Improved effect of wiring work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

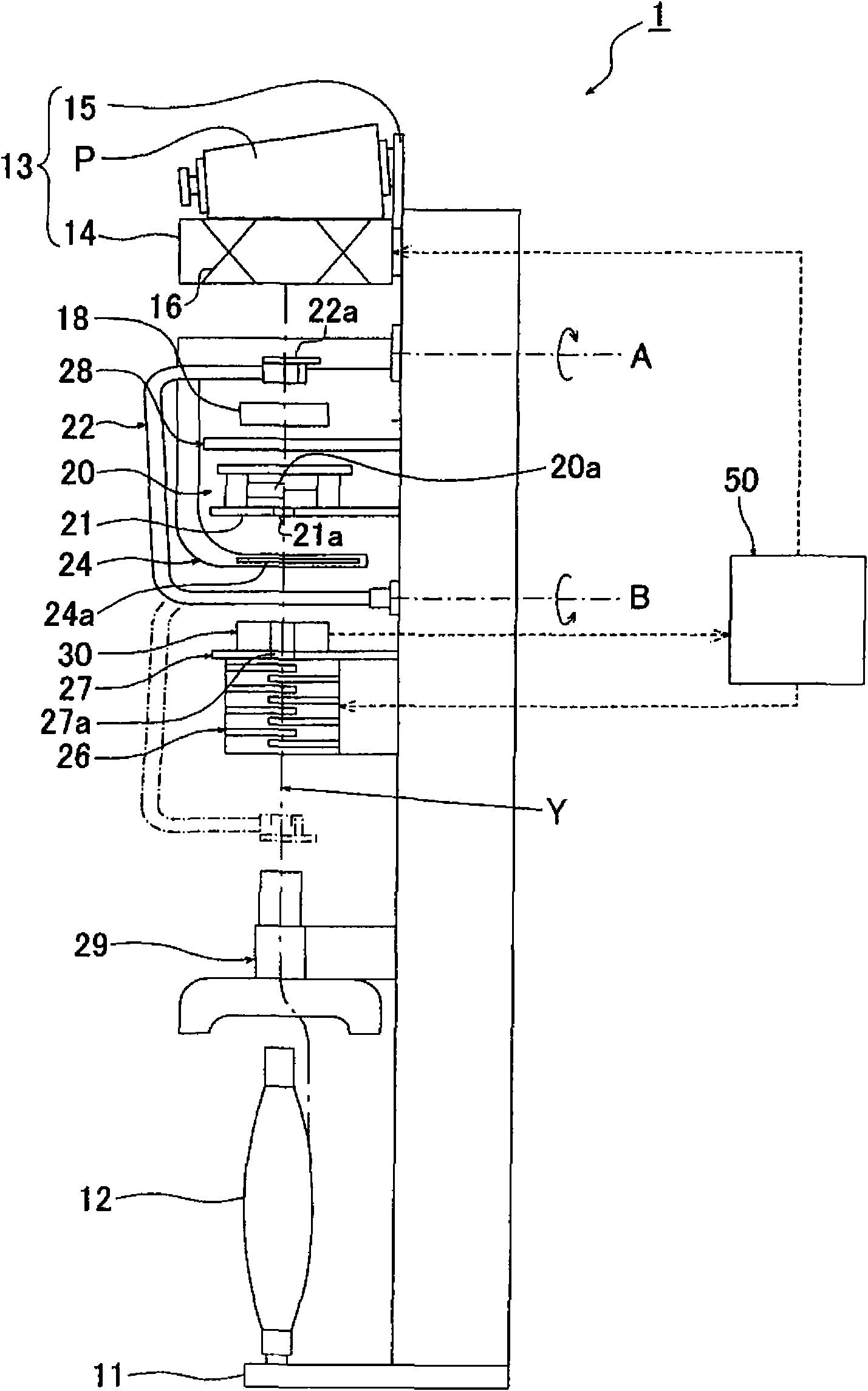

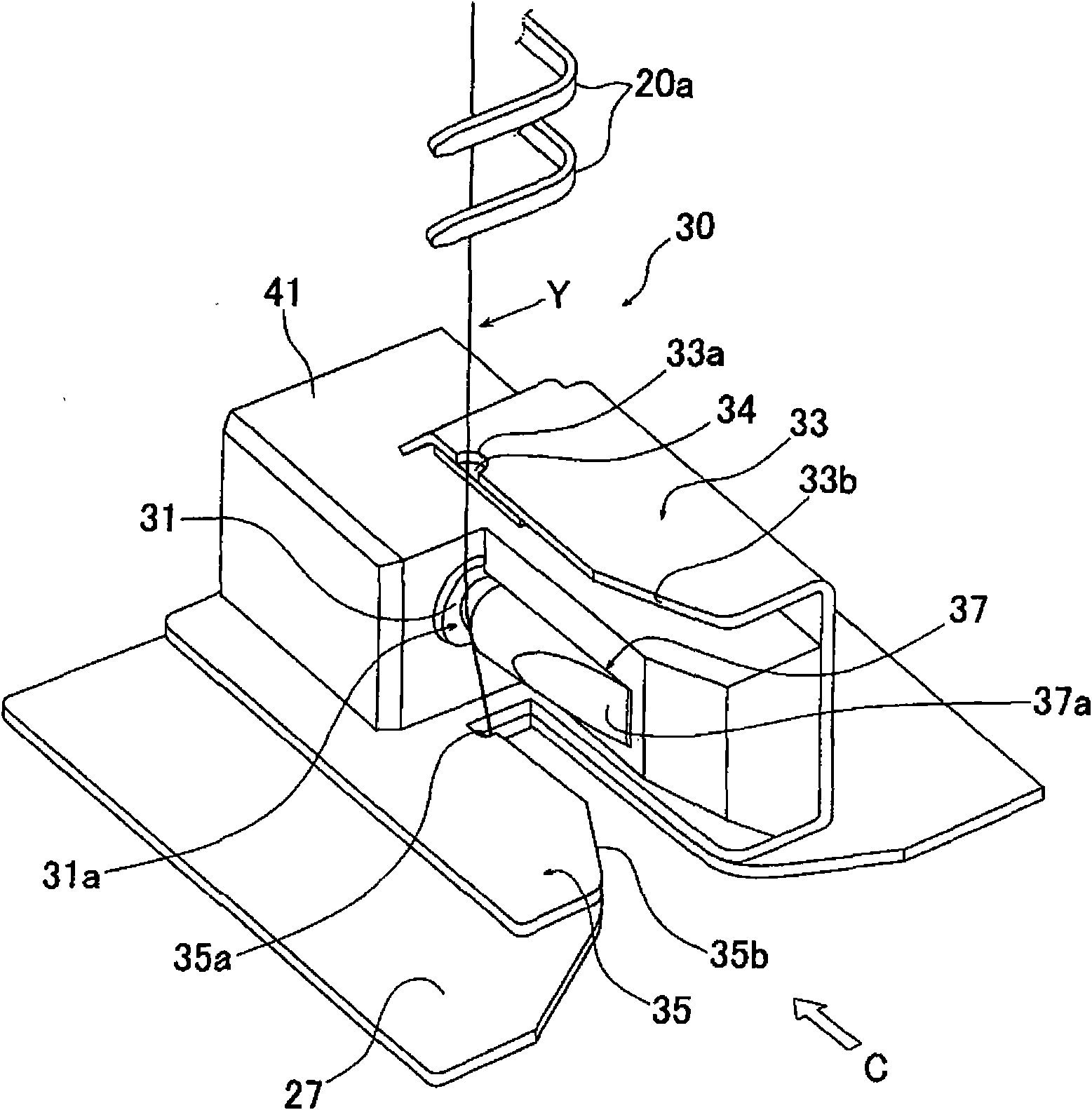

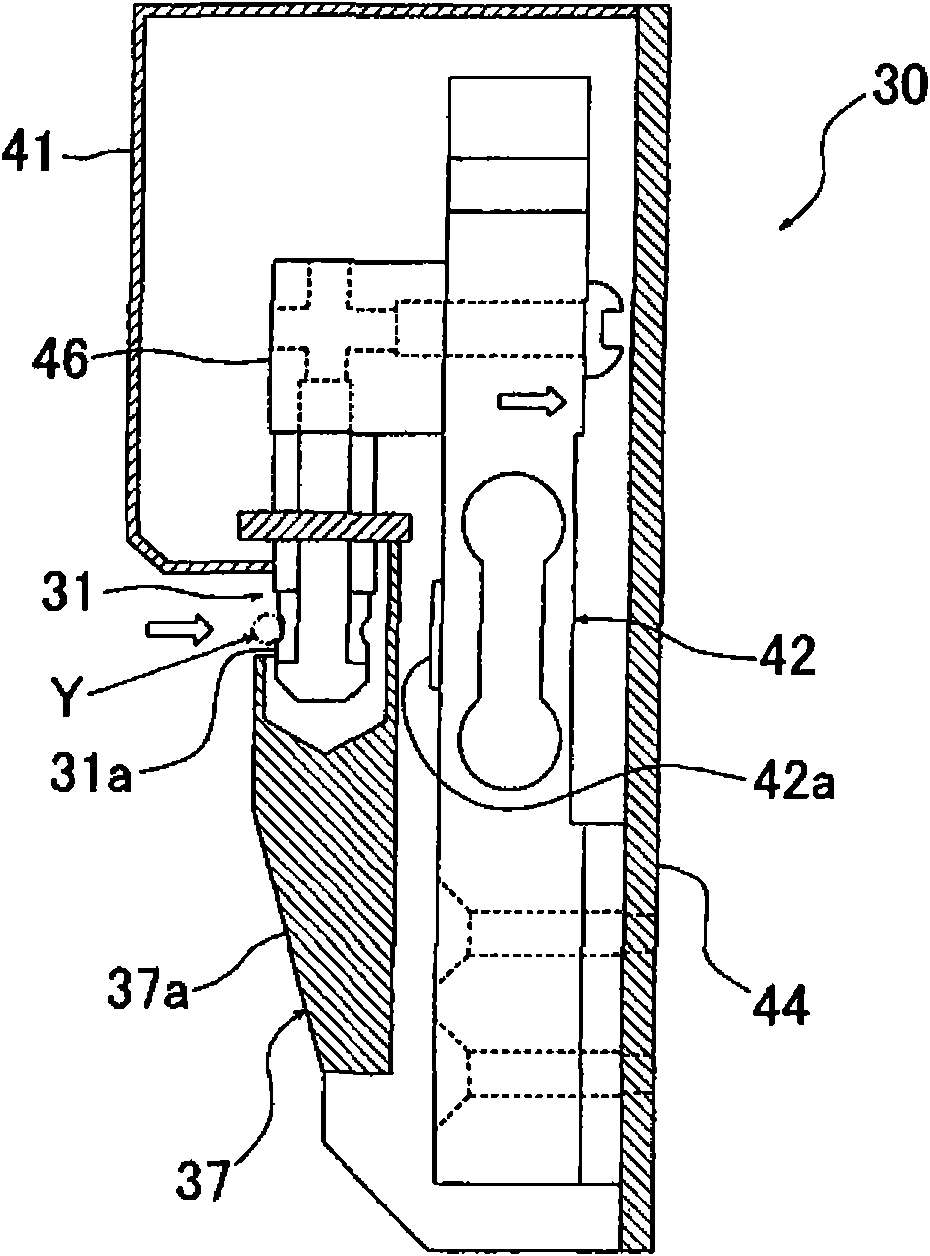

[0017] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. figure 1 It is a schematic diagram which shows the winding unit 1 of the automatic winder which concerns on one Embodiment of this invention. The winding unit 1 is equipped with a yarn supplying bobbin 12 inserted upright in the yarn supplying section 11 in the lower part, and a winding device 13 is provided in the upper part, and the winding device 13 is used to wind the yarn unwound from the yarn supplying bobbin 12. Wrap around bobbin P. Winding device 13 has: traverse drum 14 and support 15, wherein, traverse drum 14 utilizes the driving force of motor (not shown) to rotate, and support 15 then makes bobbin P contact with traverse drum 14 with appropriate contact pressure and The bobbin P is rotatably supported in this state. Traversing grooves 16 are formed on the peripheral surface of the traversing drum 14 . In this winding device 13, by r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com