Gas cylinder, in particular high-pressure gas cylinder

A high-pressure cylinder and cylinder technology, applied in fluid pressure actuating devices, engine seals, springs, etc., can solve problems such as difficulty in air pressure sealing, and achieve the effect of preventing gas loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

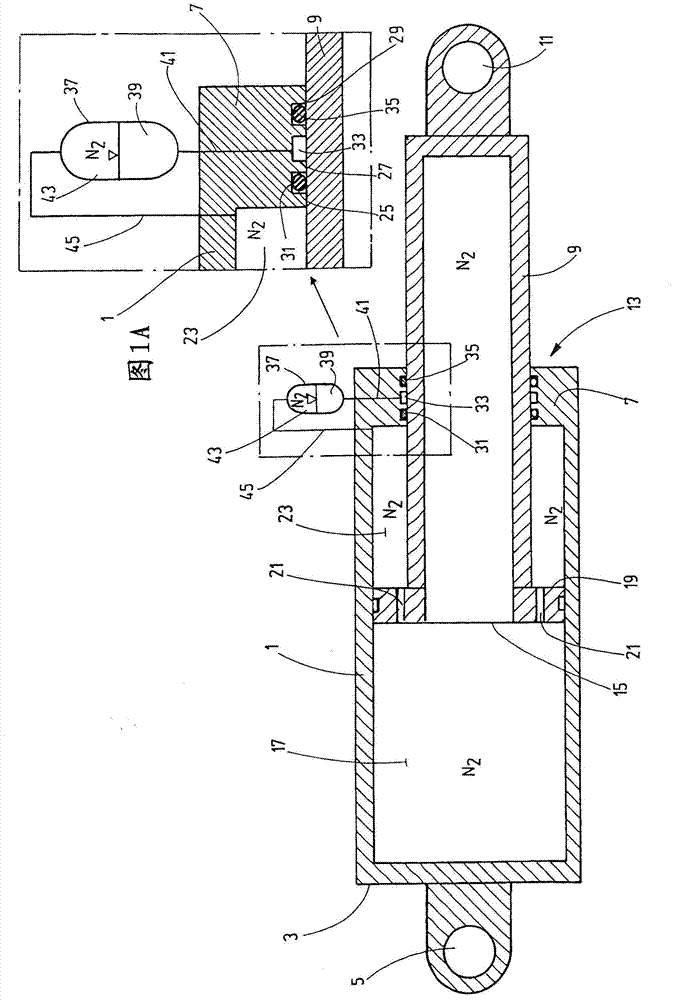

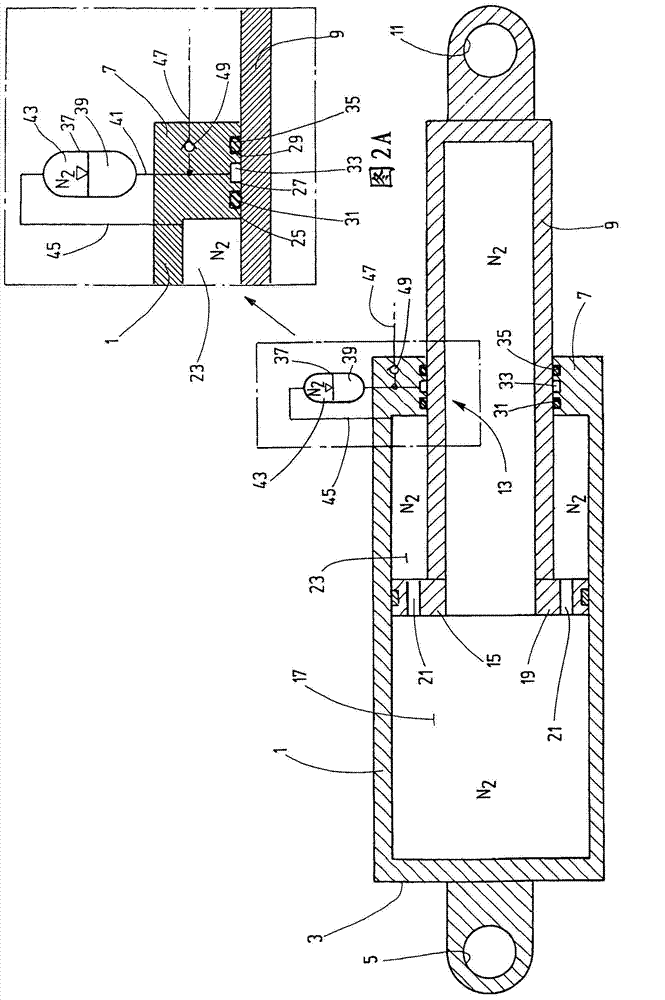

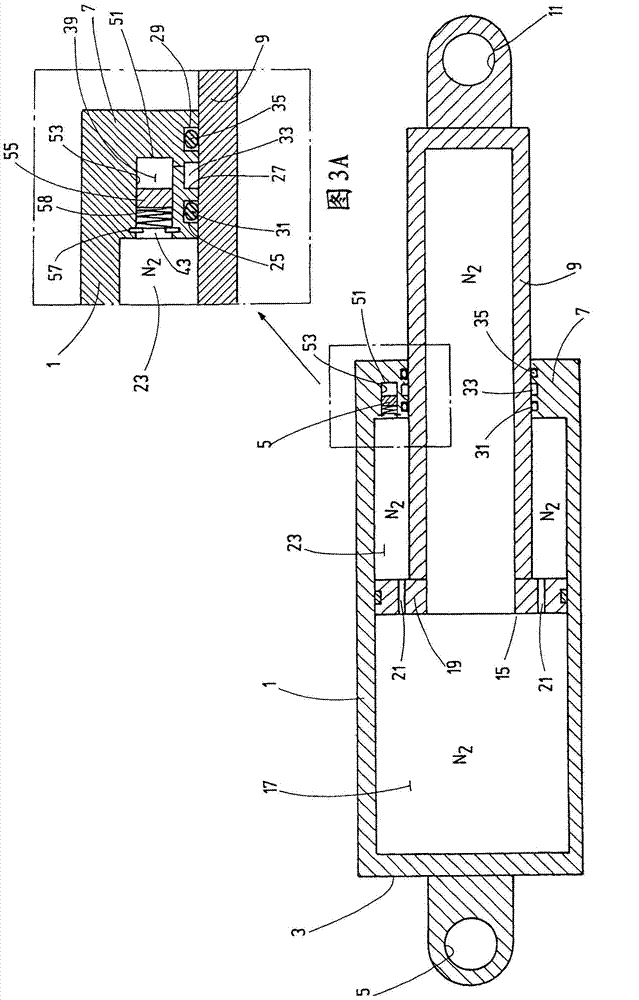

[0034] exist figure 1 The exemplary embodiment shown in has a cylinder liner 1 with a bearing bore 5 at its closed end 3 . At the opposite end, the cylinder liner 1 has a cylinder end cover part 7 which forms a sealed guide passage for a piston rod 9 on whose outer end a bearing is provided Hole 11. The sealing of the piston rod 9 relative to the end cap part 7 takes place by means of a sealing device 13 . The piston rod 9 has the shape of a cylindrical hollow body, thus forming a tube which is open at its inner end 15 towards the pressure chamber 17 of the cylinder liner 1 . The pressure chamber 17 is filled (via a filling connection not shown) with a working gas at high pressure, for example N2. On the open end 15 of the piston rod 9 there is a piston-shaped guide element 19 which is guided on the inner wall of the cylinder liner 1 during the movement of the piston rod 9 . Channels 21 are provided in the guide part 19 , each channel communicating the pressure chamber 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com