Component different-surface-parallel-hole form and position deviation visual measuring method and device

A form-position deviation and visual measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of complex measurement steps, easily damaged parts and measurement equipment, time-consuming measurement process, etc., to achieve fast measurement process, reduce Measuring costs, the effect of improving product productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

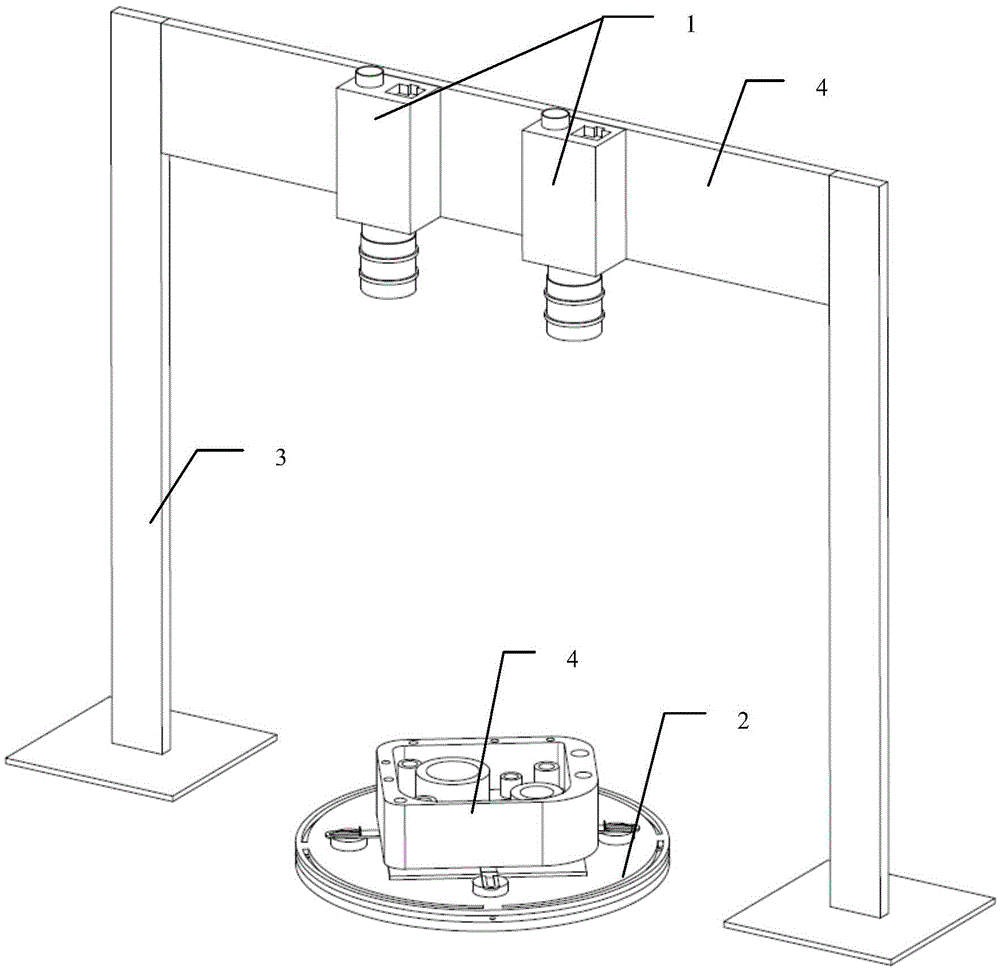

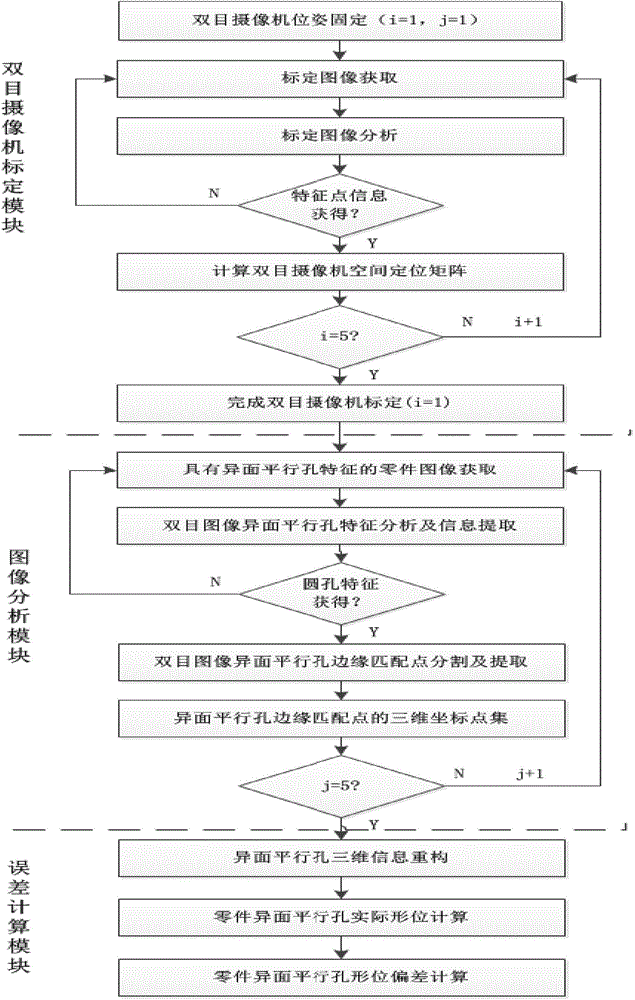

[0055] refer to figure 1 and figure 2 , in order to capture multiple images of the measured part 4 in different poses, and to ensure the relative stability of the position information of the measured part 4 during the measurement process, the preferred embodiment of the present invention firstly provides a shape deviation The visual measuring device comprises a camera and a part fixing table 2, wherein the camera is a binocular camera 1, and is vertically installed on the beam 4 of the camera bracket 3, and the parts fixing table 2 is a rotatable fixing table, And horizontally arranged under the binocular camera 1, the binocular camera 1 is parallel in space and its optical axis is perpendicular to the end surface of the part fixing table 2.

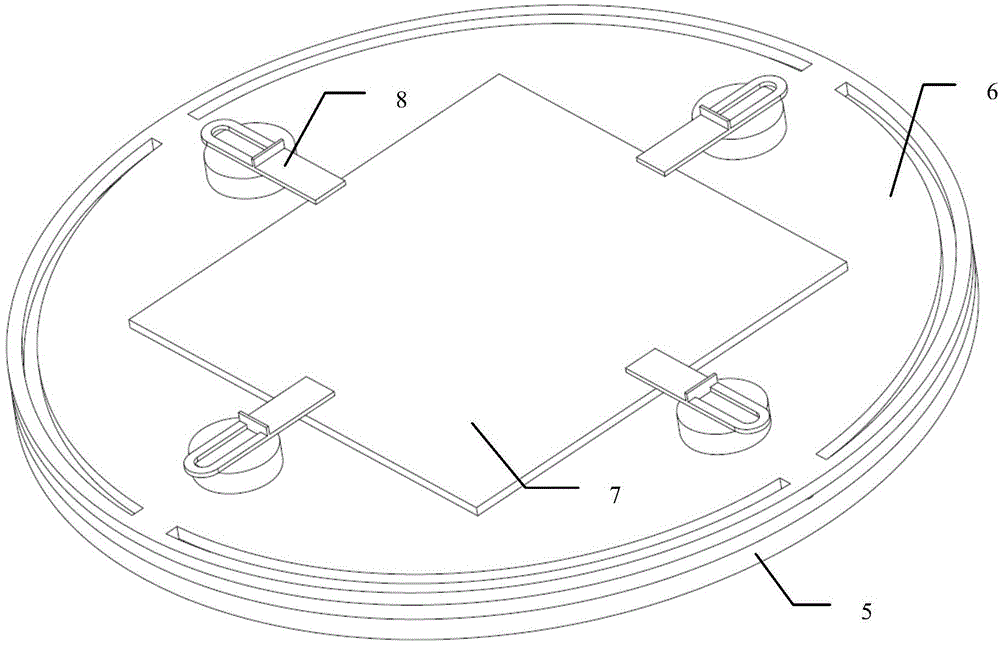

[0056] The part fixing table 2 includes a bottom fixed disc 5 and an upper rotatable disc 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com