Patents

Literature

39 results about "Pulse energy density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

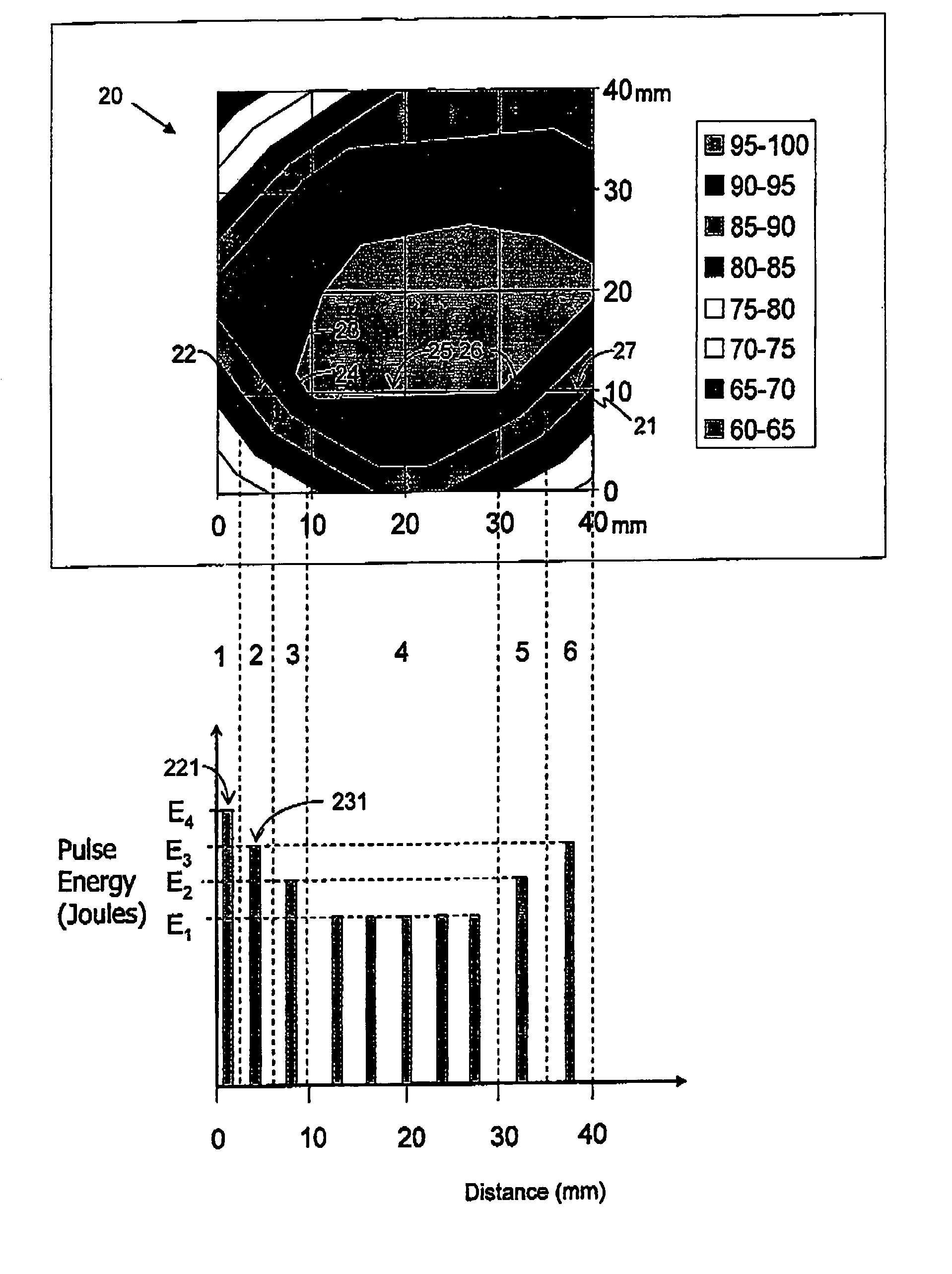

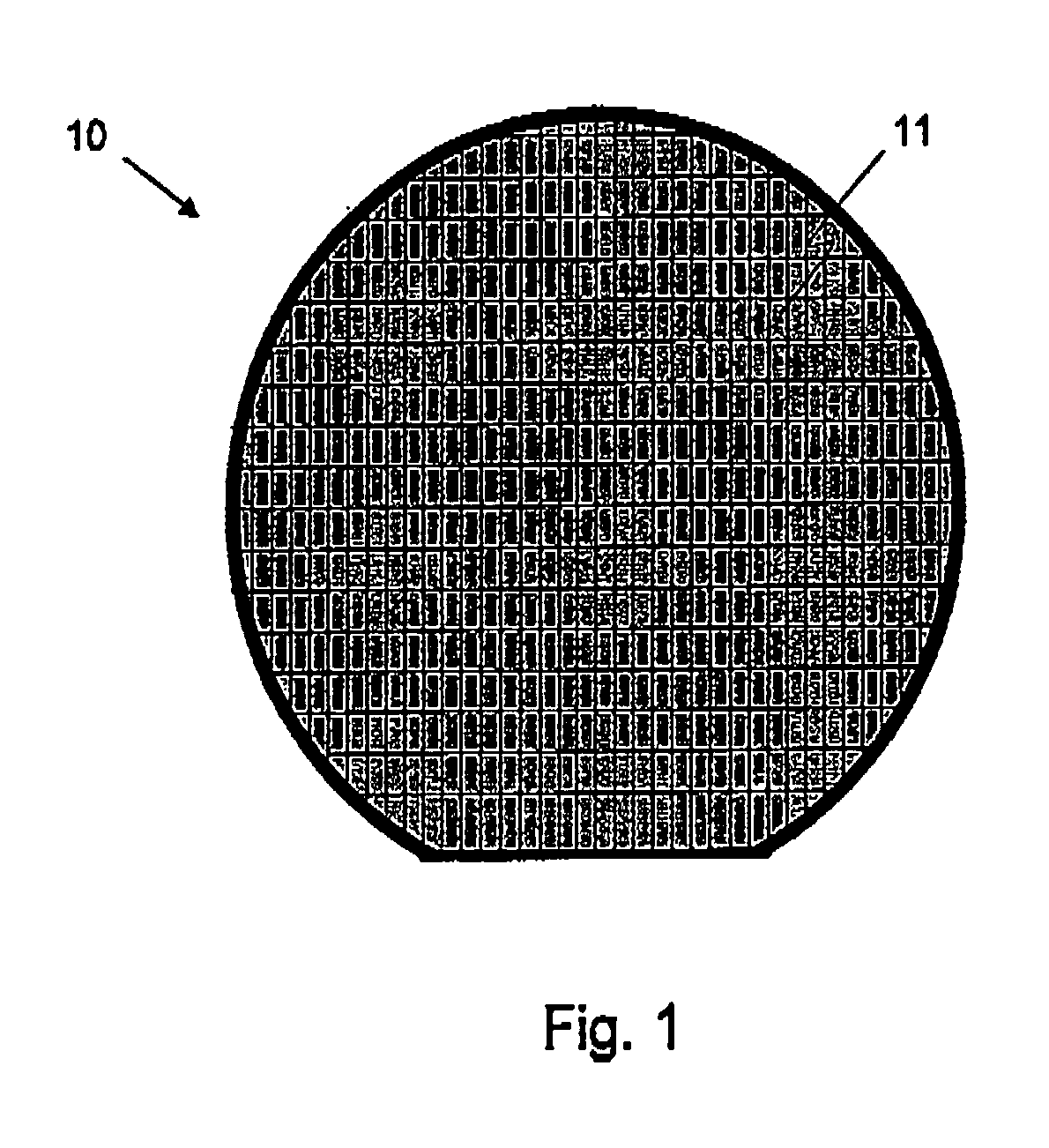

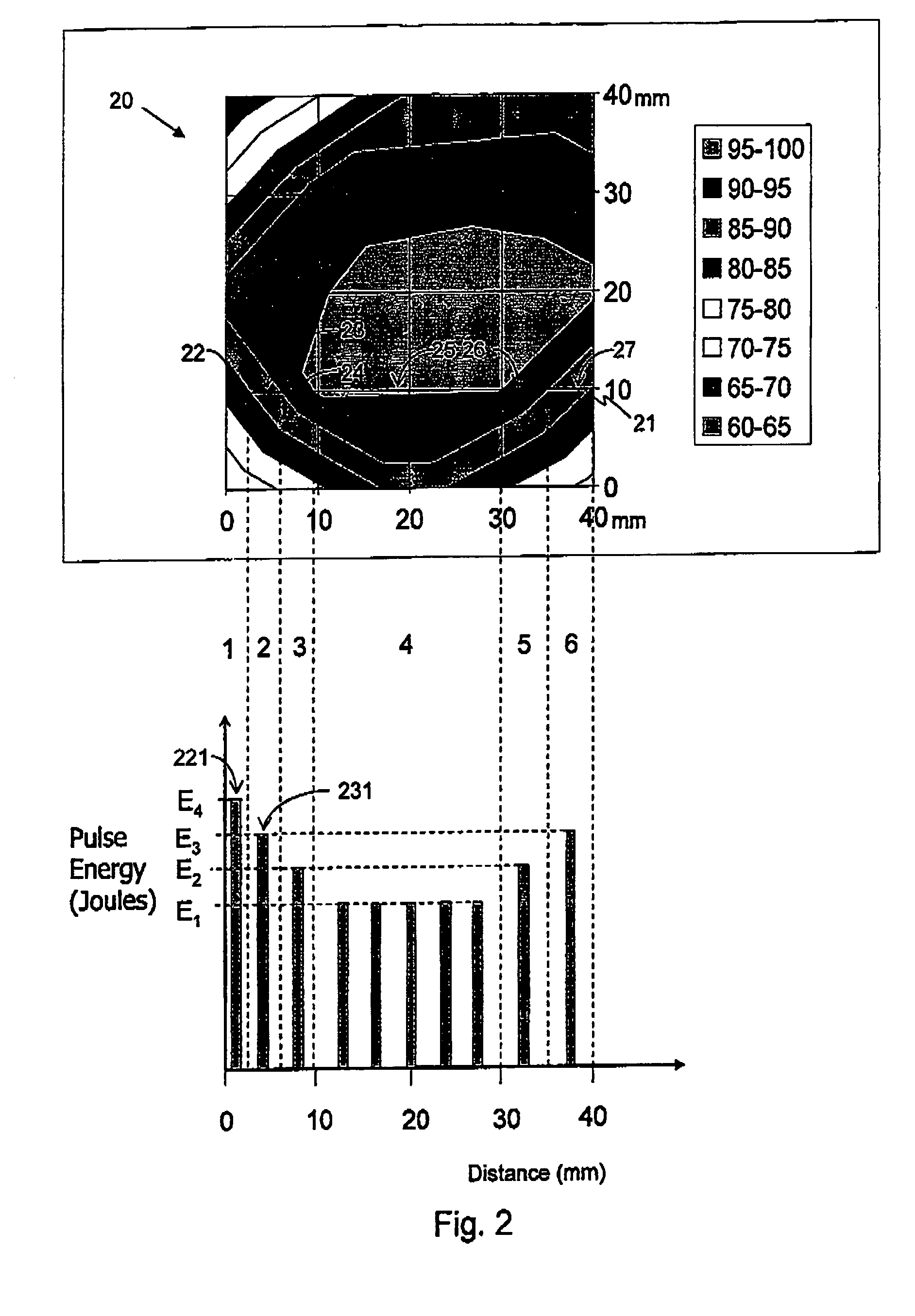

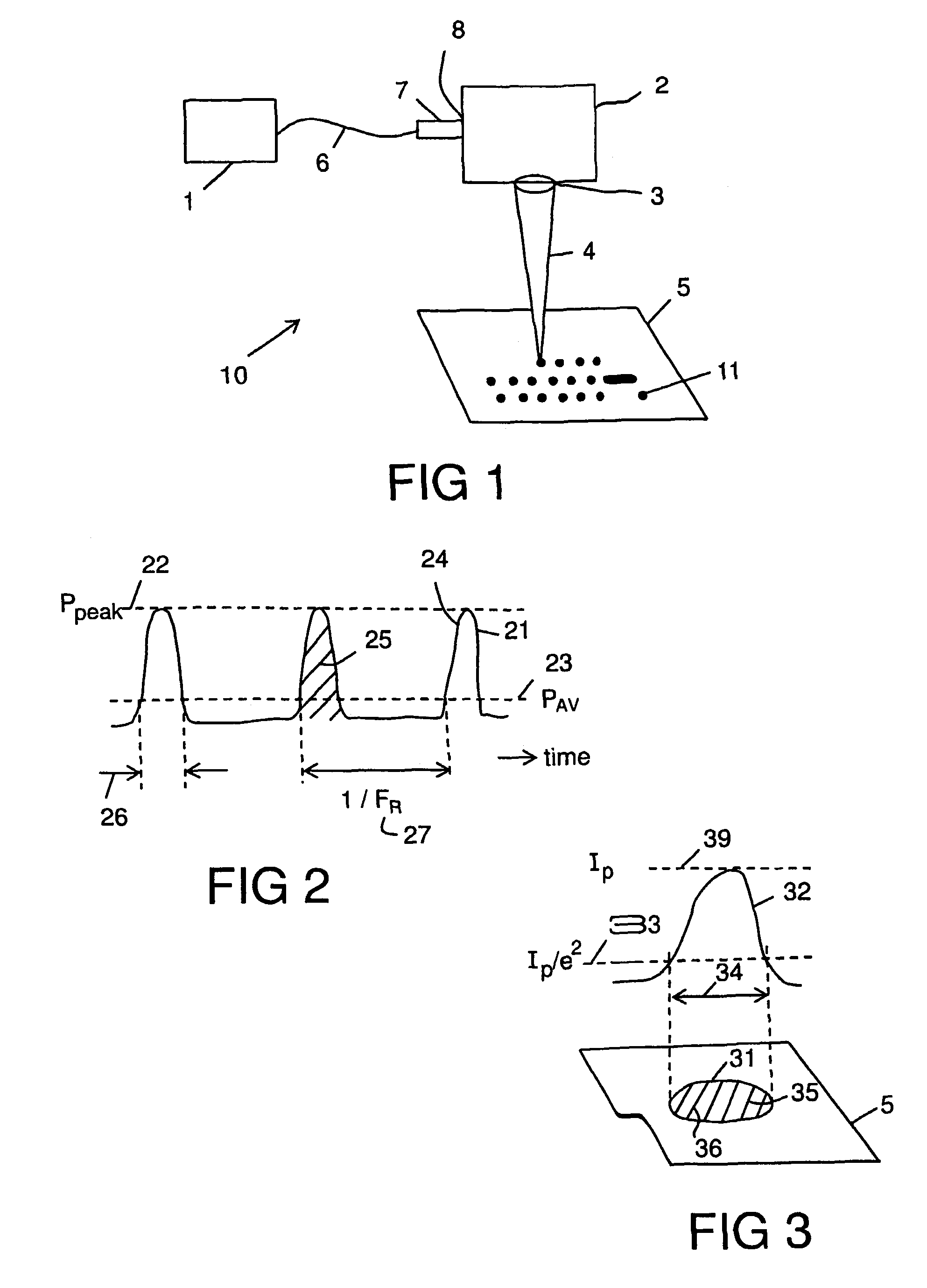

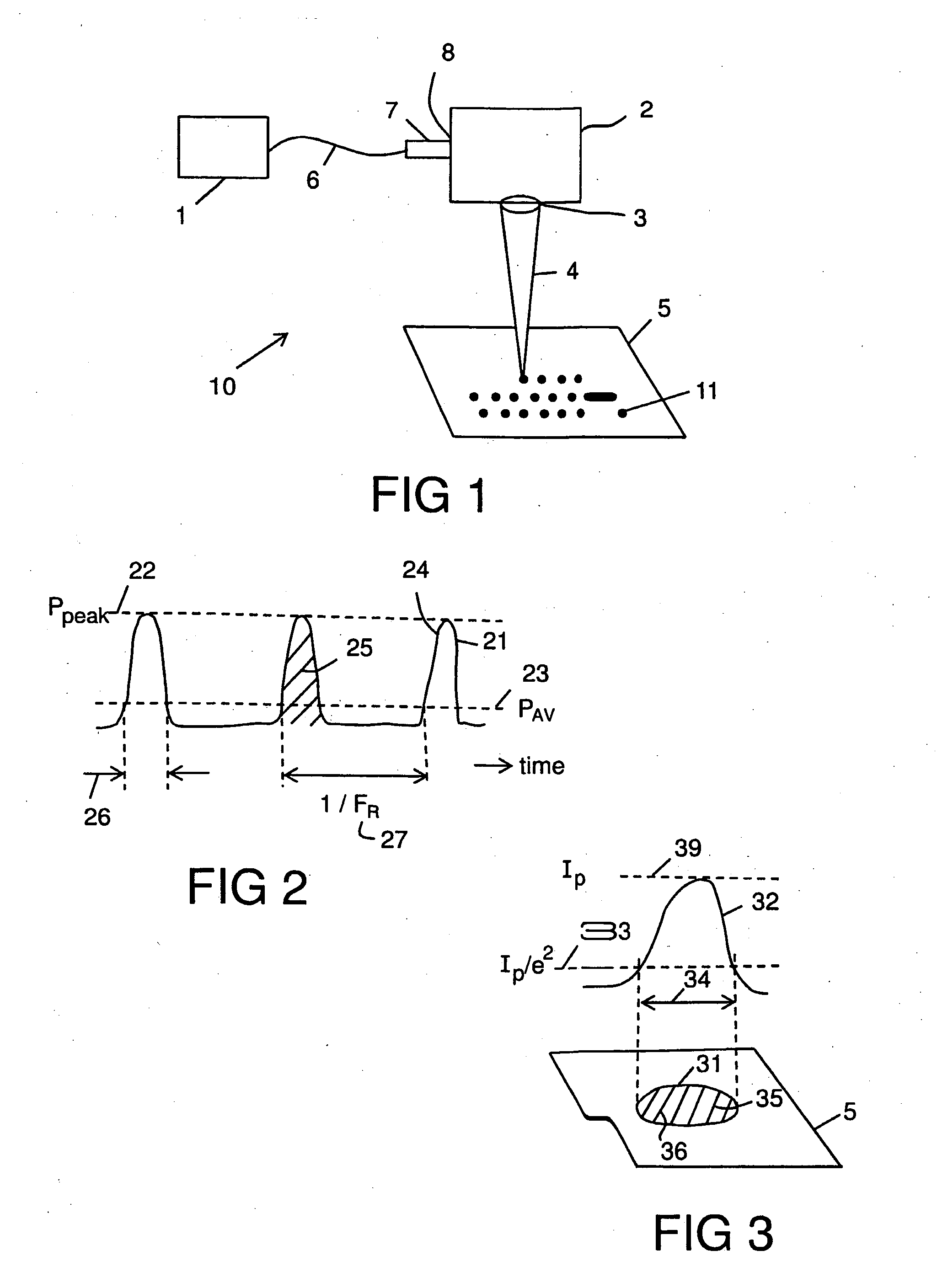

Program-controlled dicing of a substrate using a pulsed laser

InactiveUS7776720B2Facilitate dicing of the substrateControl damageSemiconductor/solid-state device manufacturingPrinted circuit manufactureChemical reactionPulse rate

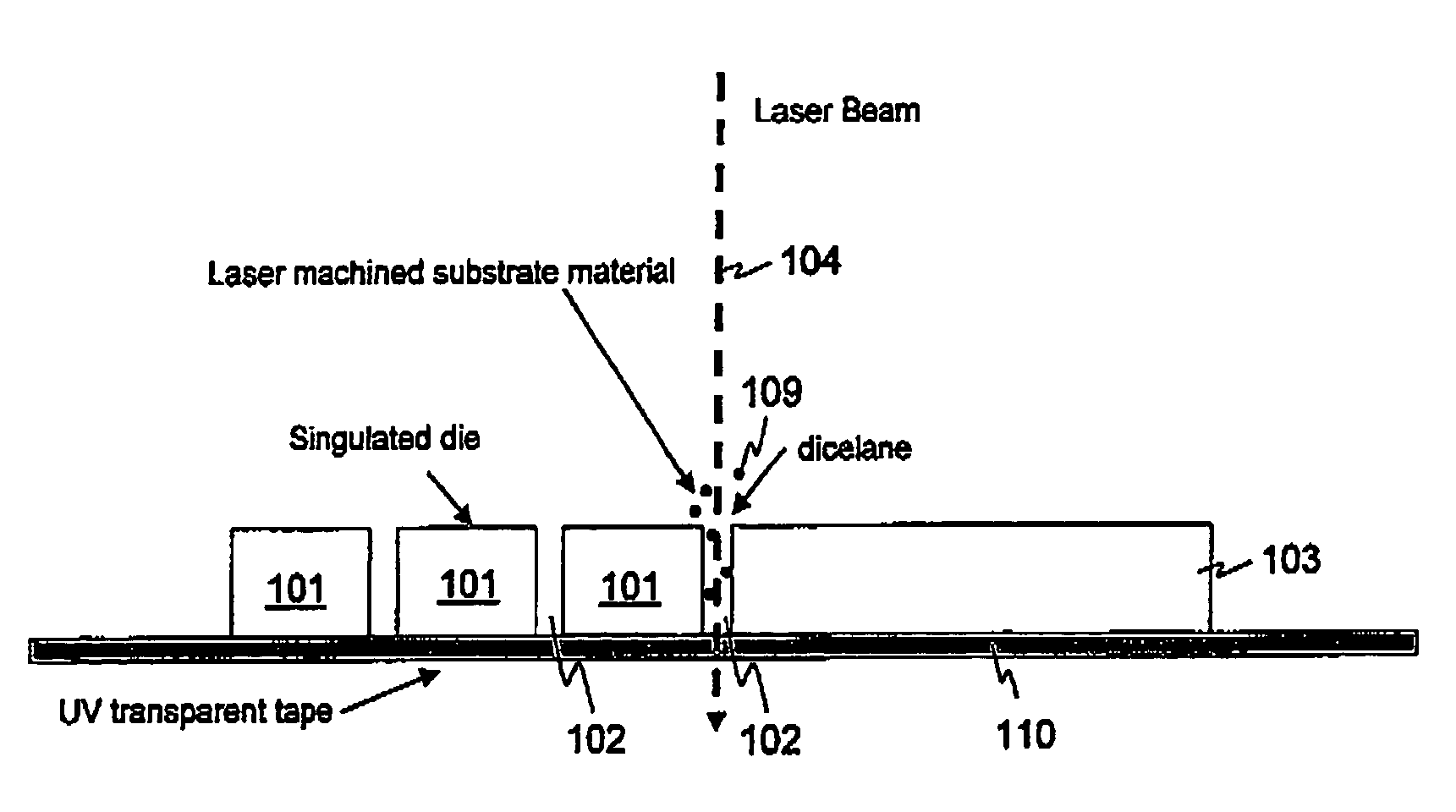

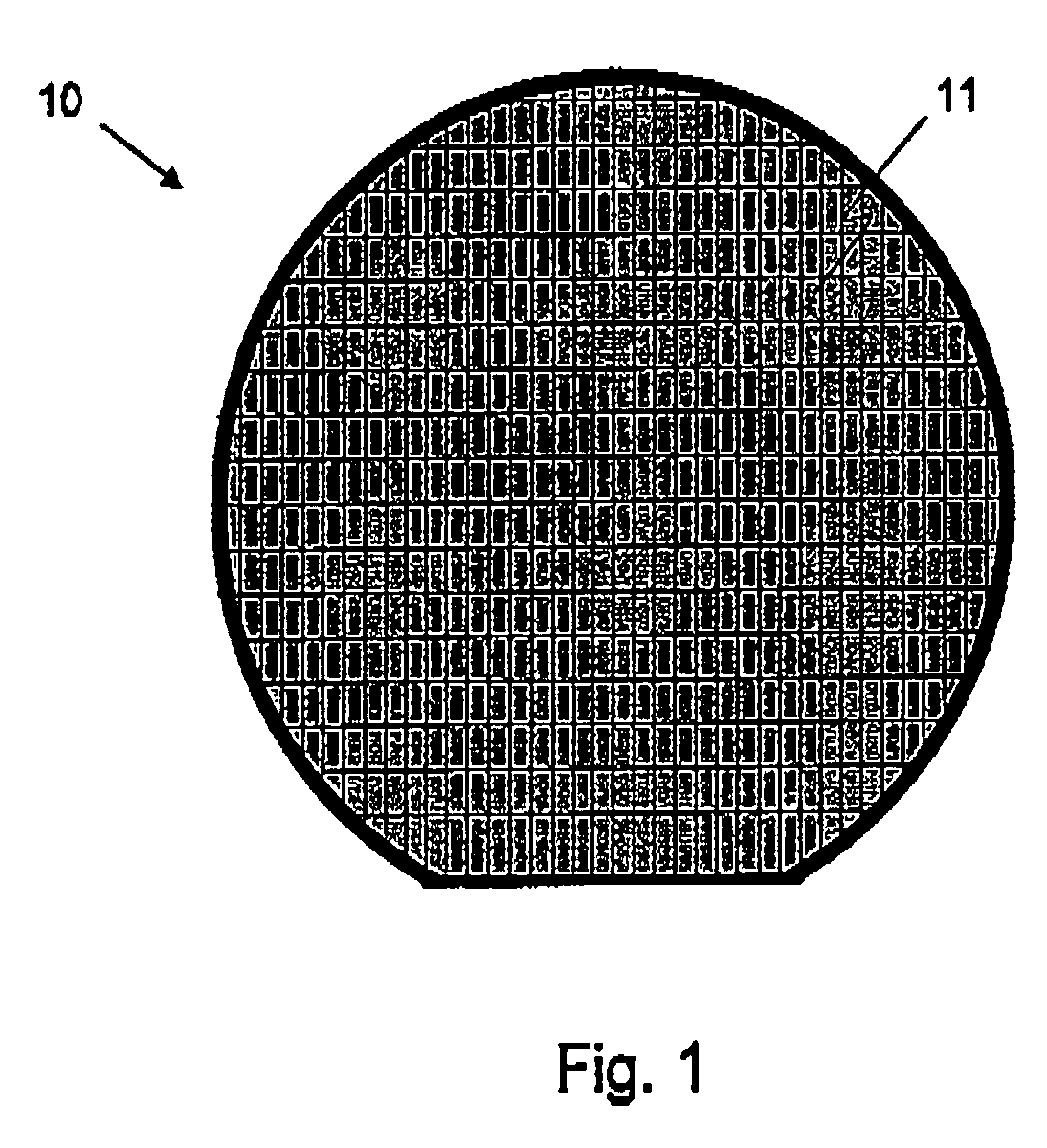

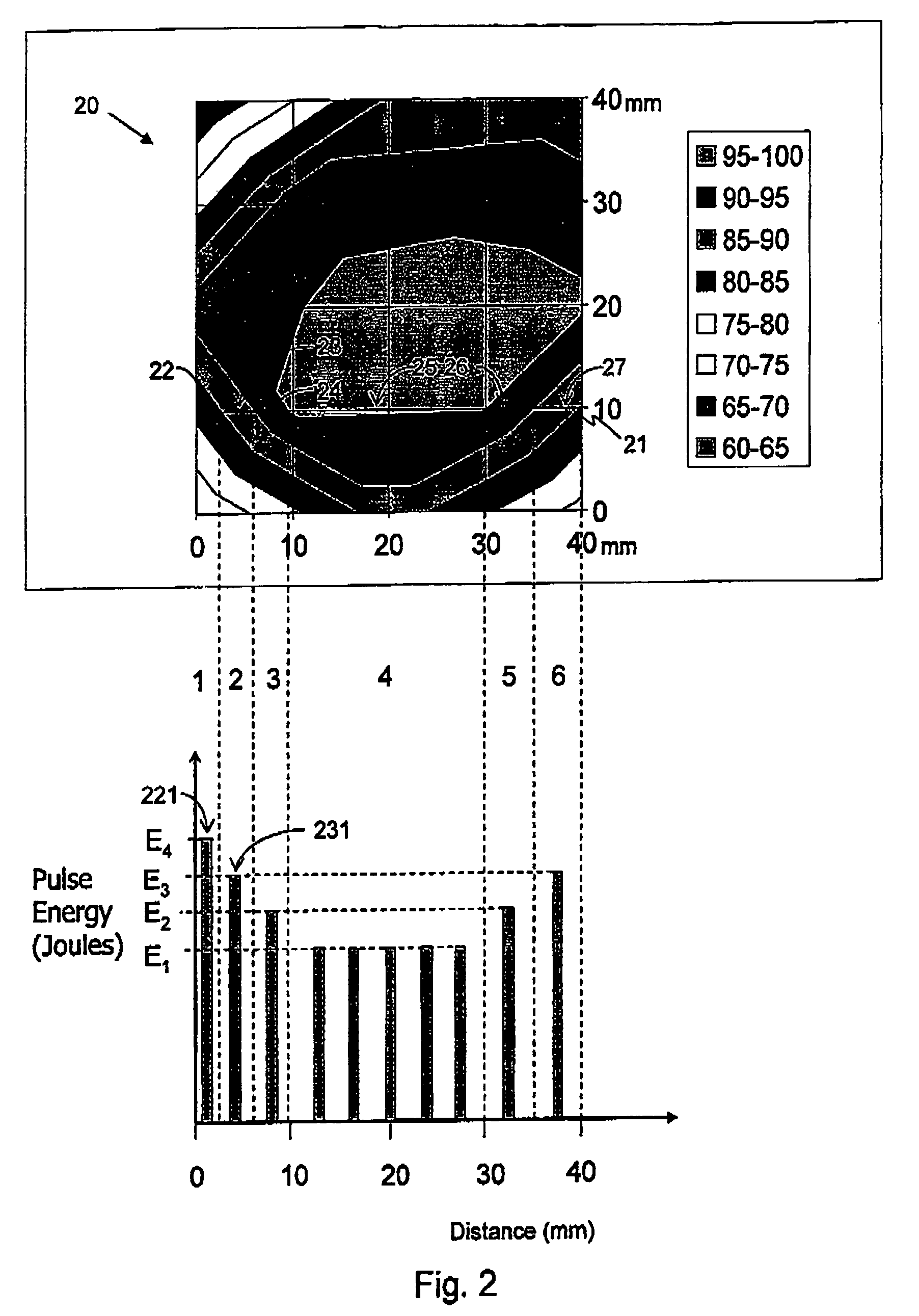

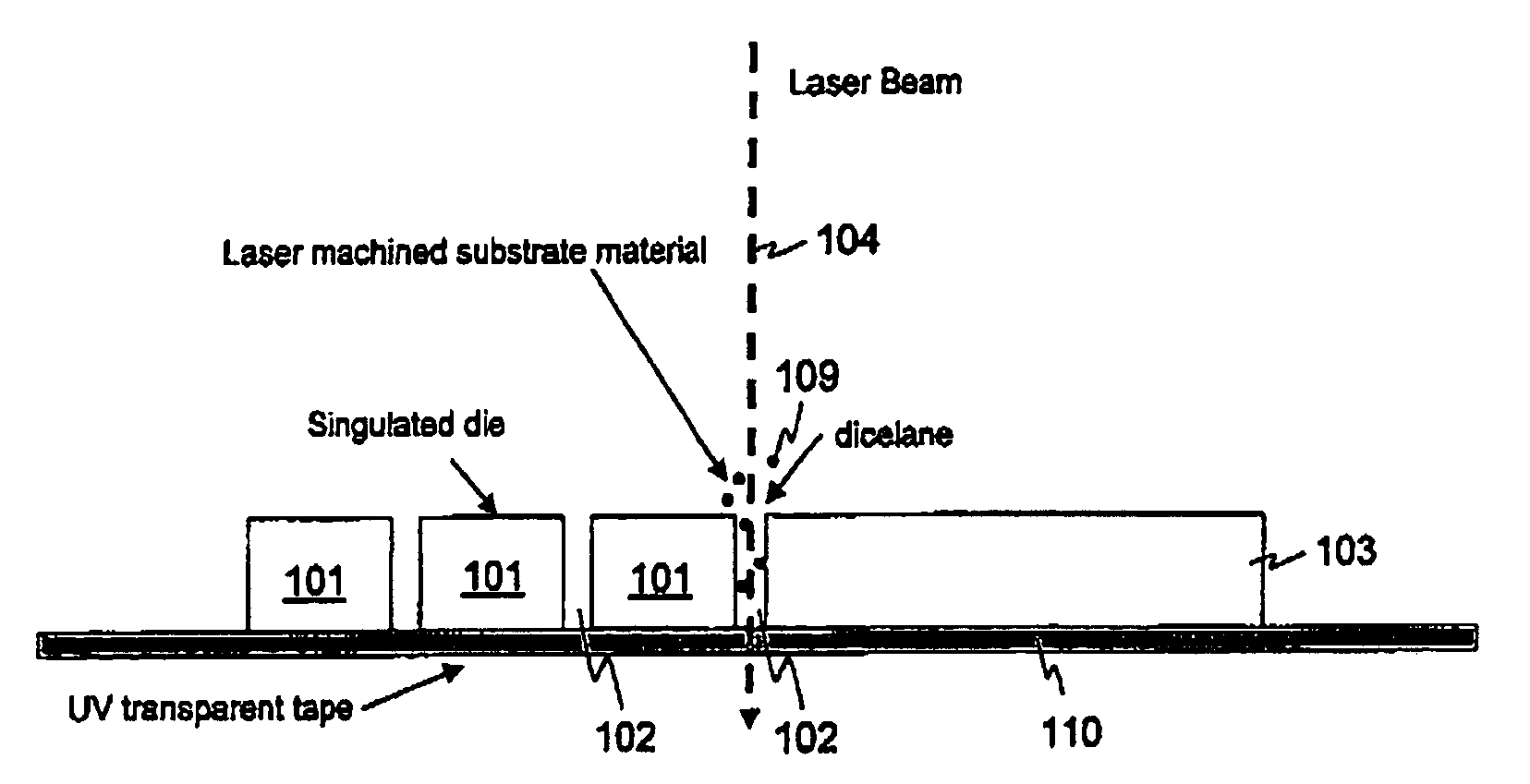

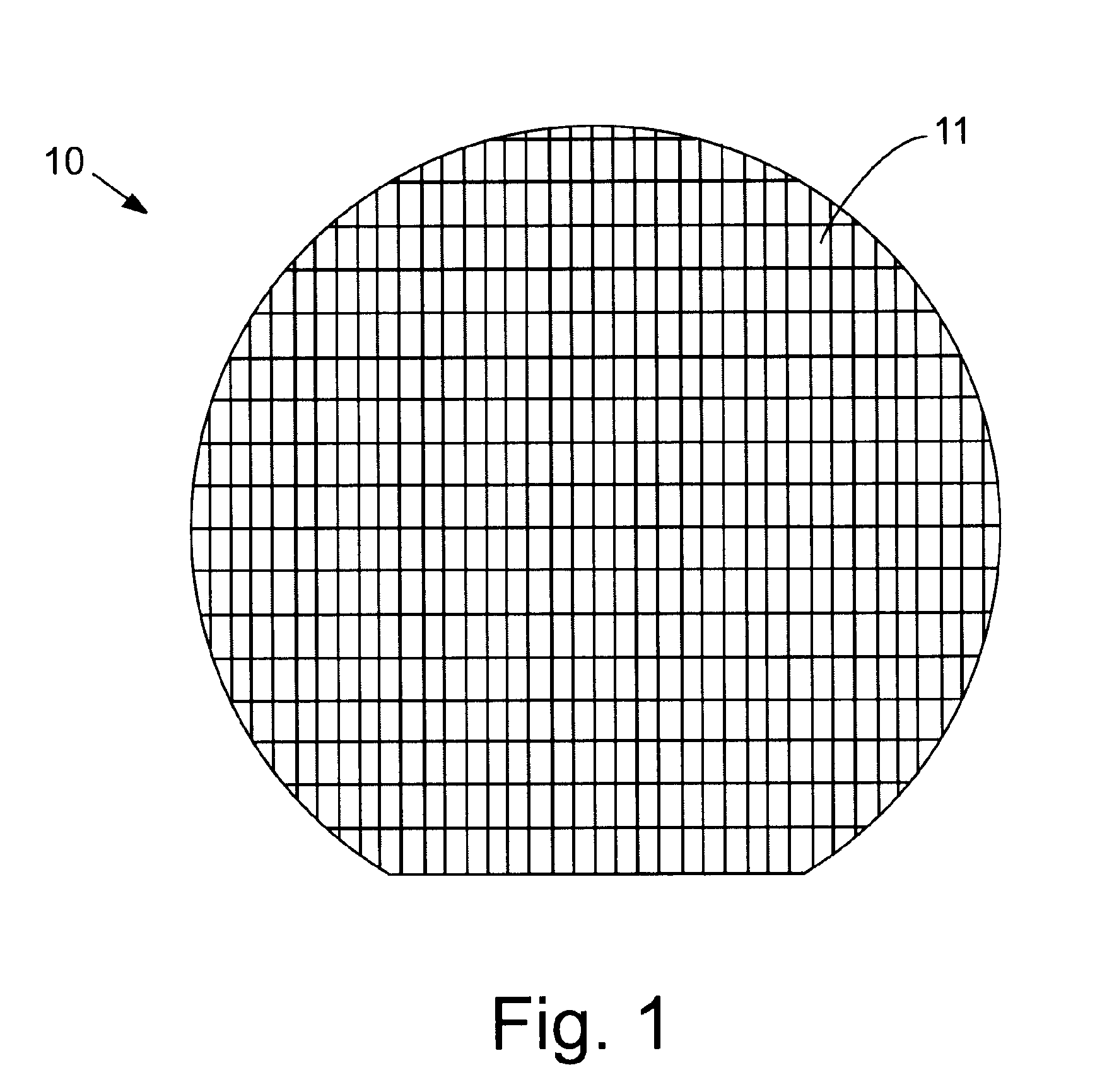

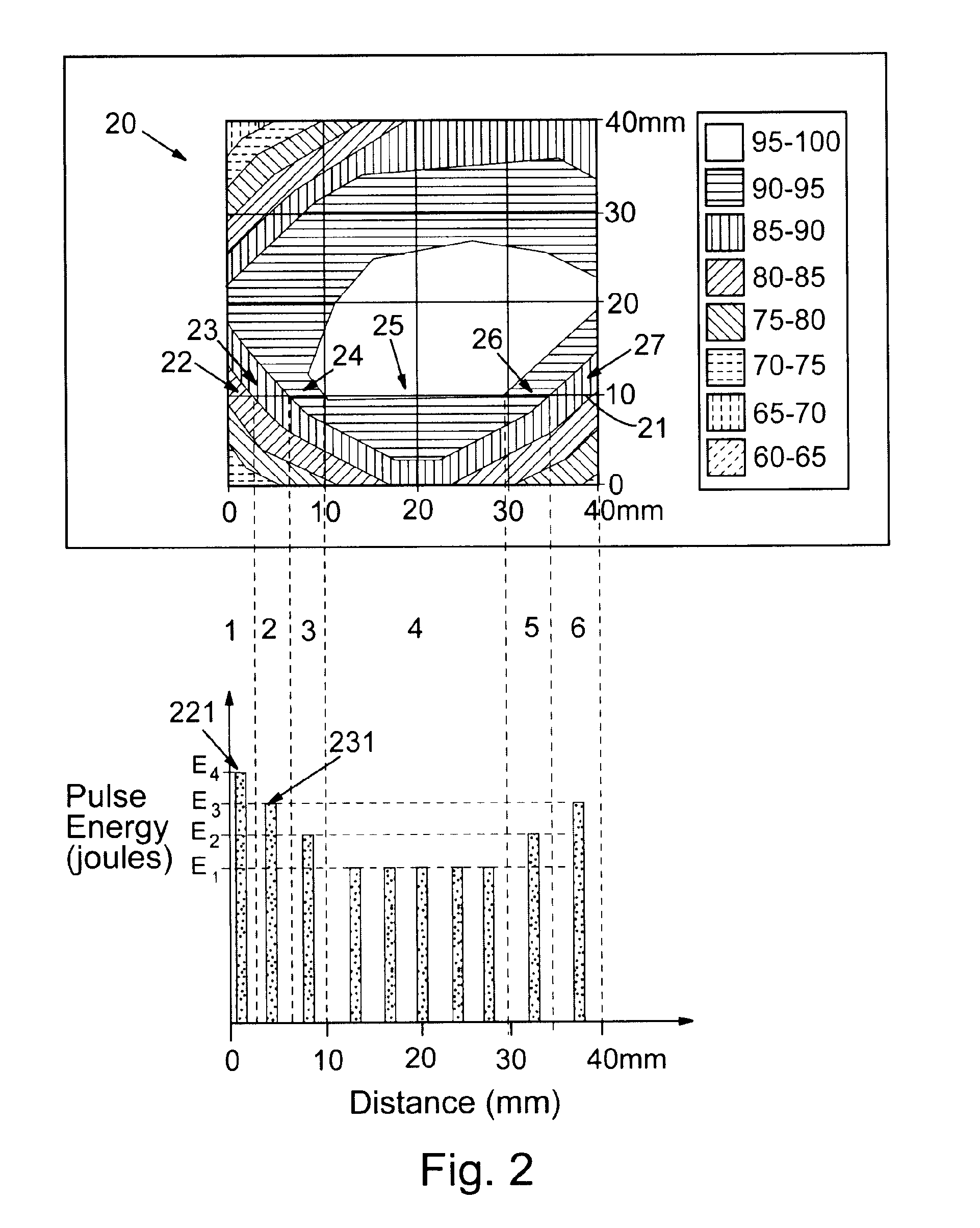

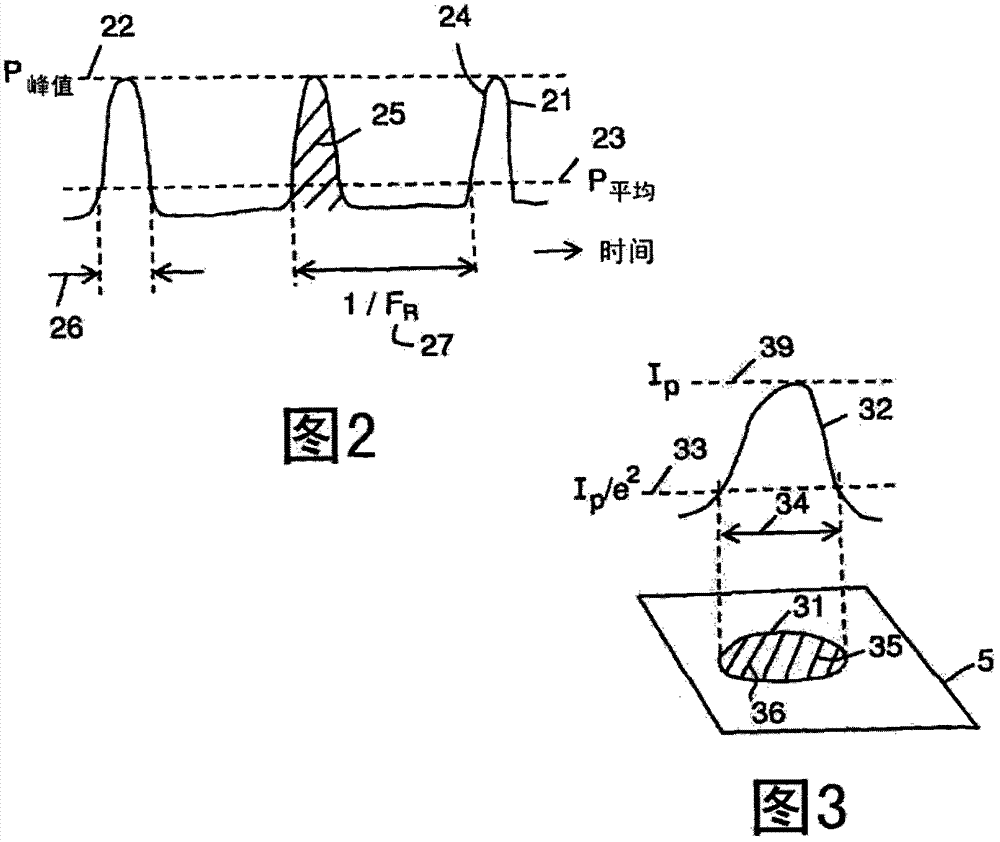

A substrate is diced using a program-controlled pulsed laser beam apparatus having an associated memory for storing a laser cutting strategy file. The file contains selected combinations of pulse rate Deltat, pulse energy density E and pulse spatial overlap to machine a single layer or different types of material in different layers of the substrate while restricting damage to the layers and maximising machining rate to produce die having predetermined die strength and yield. The file also contains data relating to the number of scans necessary using a selected combination to cut through a corresponding layer. The substrate is diced using the selected combinations. Gas handling equipment for inert or active gas may be provided for preventing or inducing chemical reactions at the substrate prior to, during or after dicing.

Owner:XSIL TECH

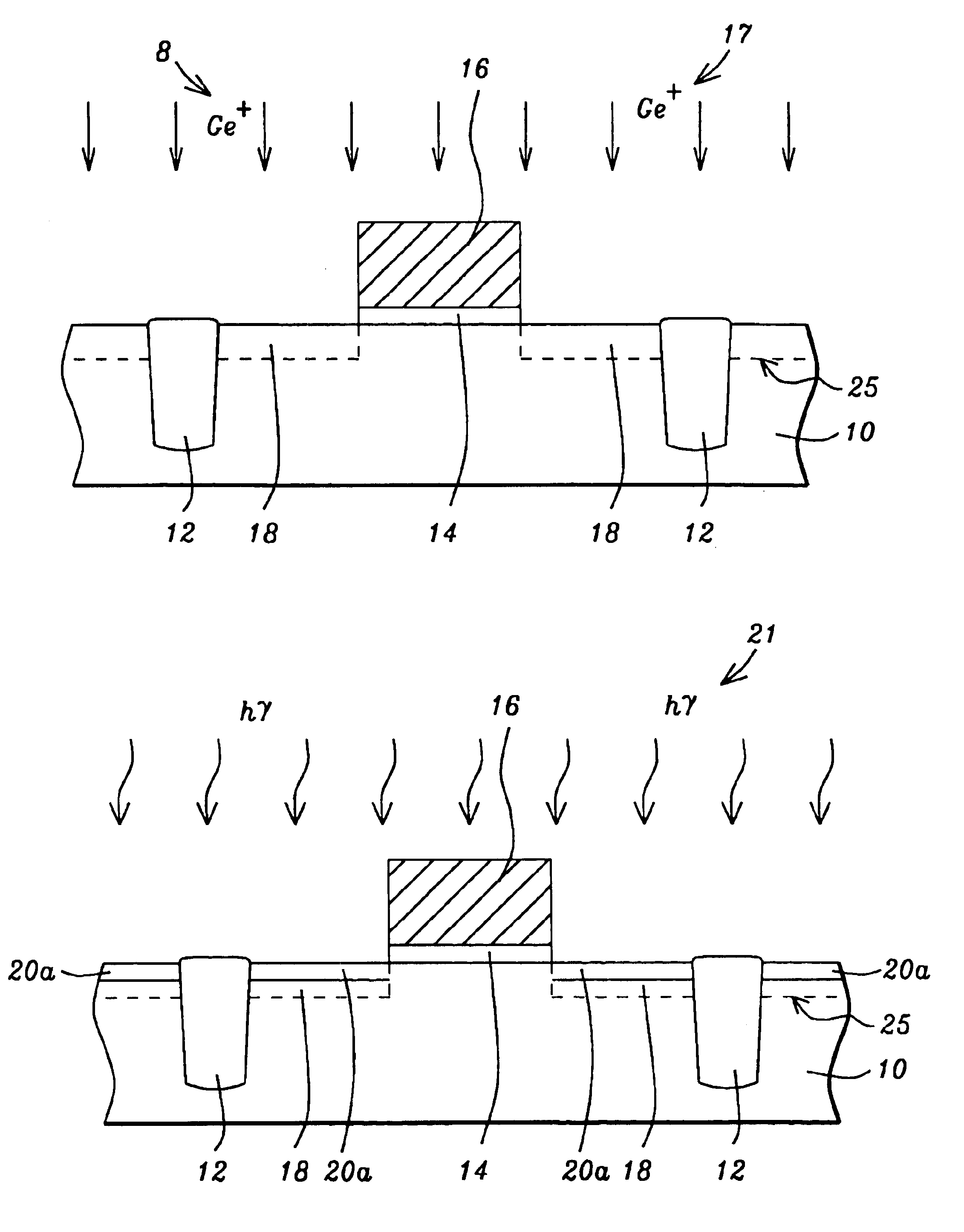

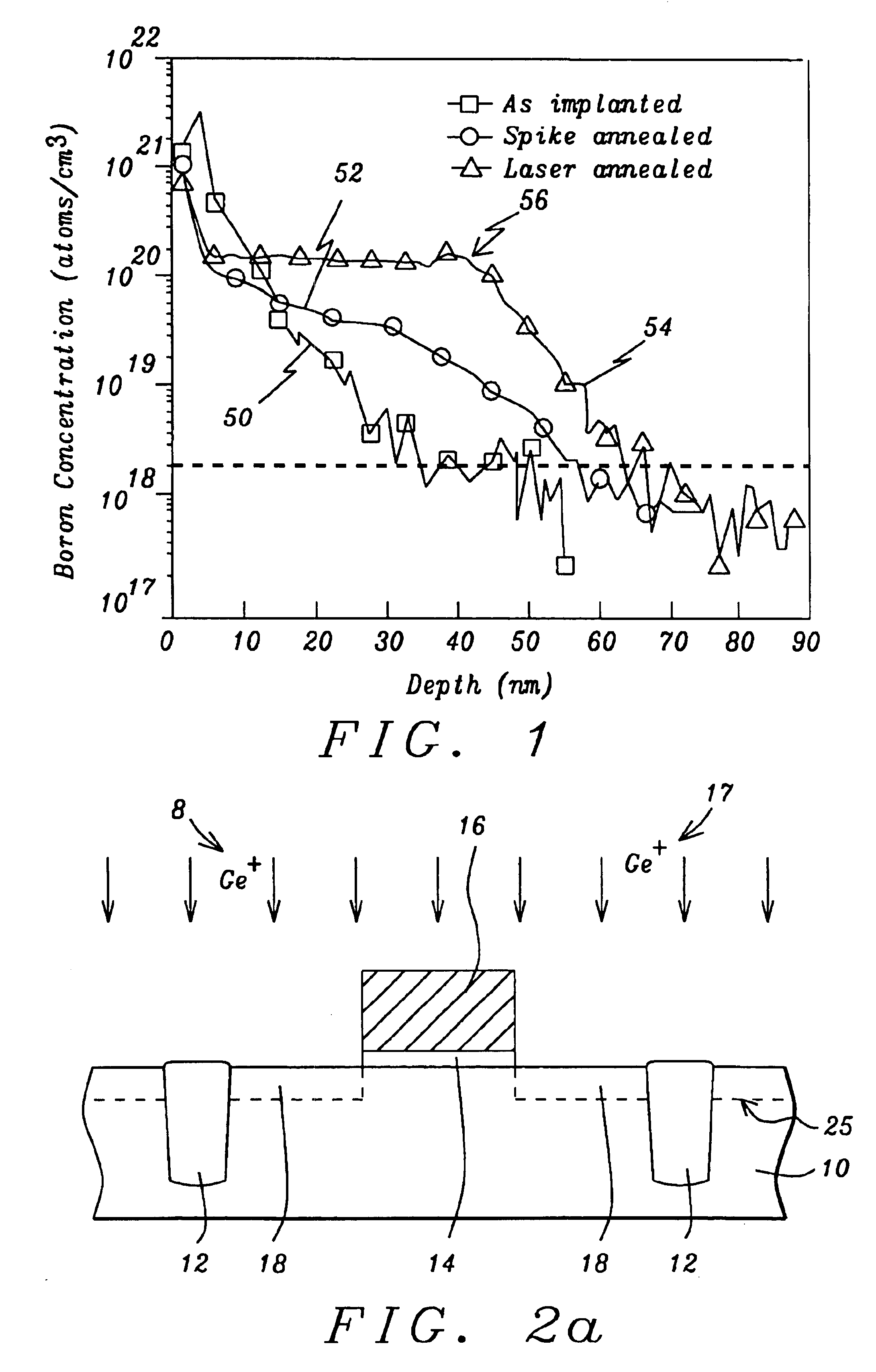

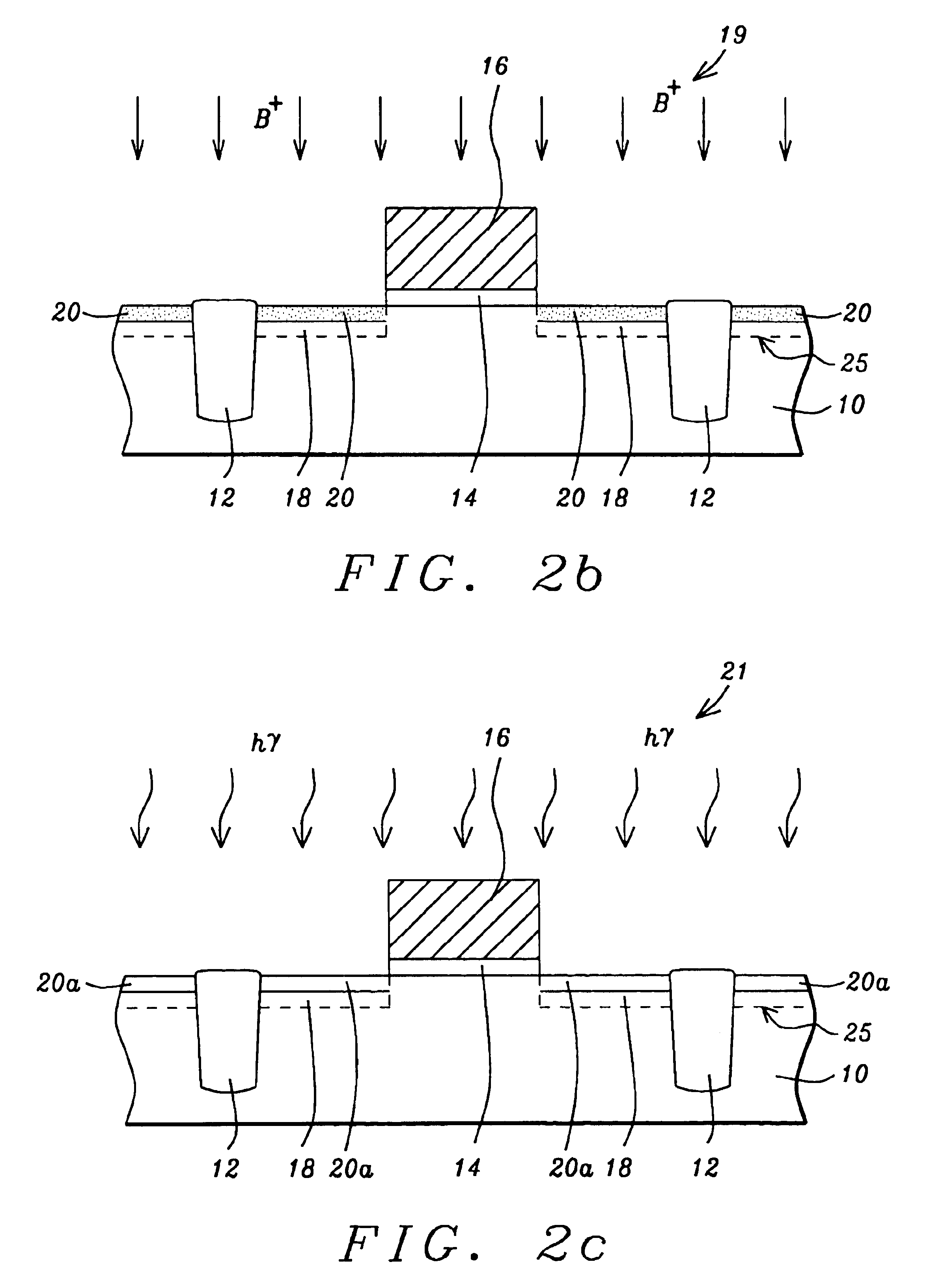

Method of multiple pulse laser annealing to activate ultra-shallow junctions

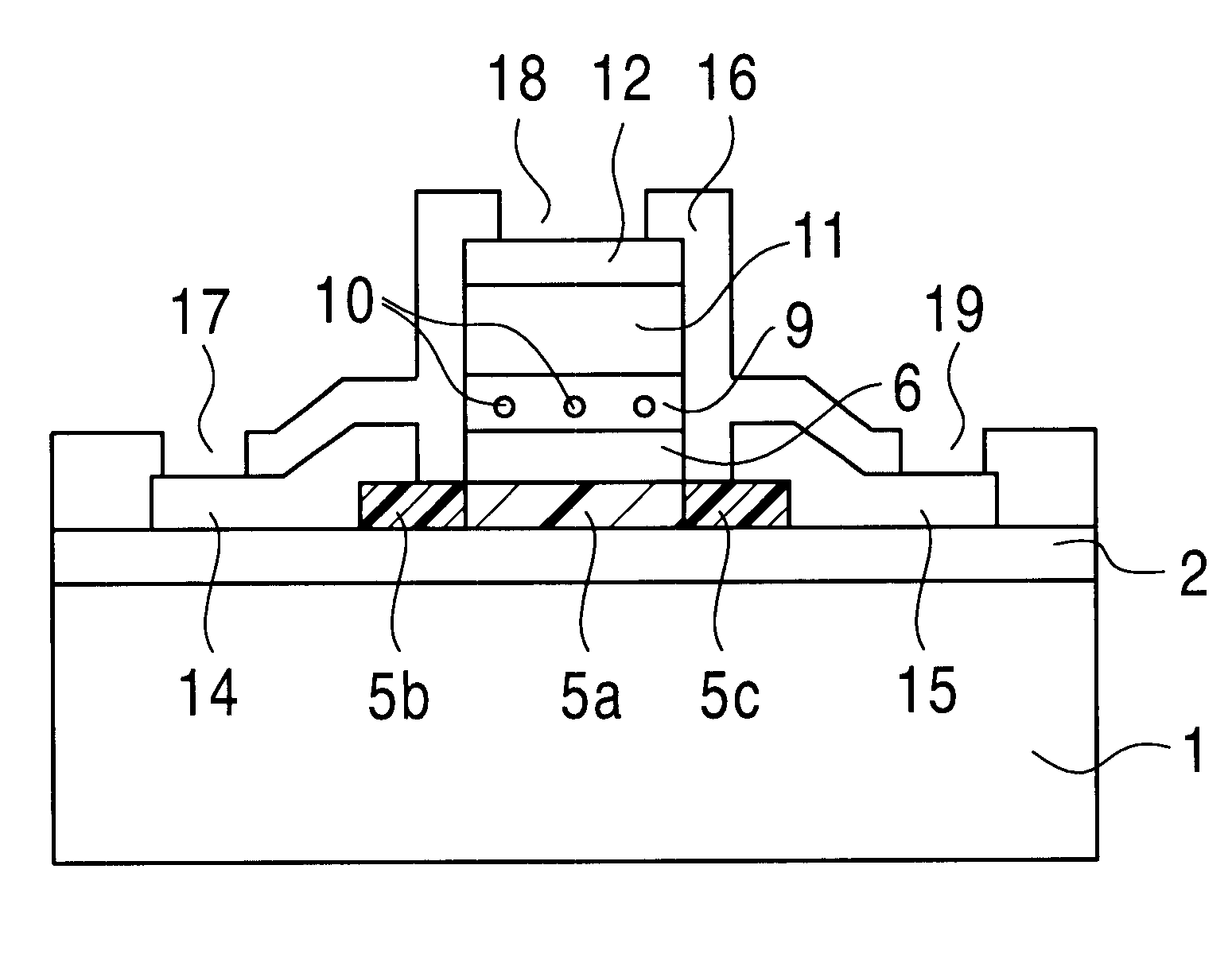

A method for forming a highly activated ultra shallow ion implanted semiconductive elements for use in sub-tenth micron MOSFET technology is described. A key feature of the method is the ability to activate the implanted impurity to a highly active state without permitting the dopant to diffuse further to deepen the junction. A selected single crystalline silicon active region is first amorphized by implanting a heavy ion such as silicon or germanium. A semiconductive impurity for example boron is then implanted and activated by pulsed laser annealing whereby the pulse fluence, frequency, and duration are chosen to maintain the amorphized region just below it's melting temperature. It is found that just below the melting temperature there is sufficient local ion mobility to secure the dopant into active positions within the silicon matrix to achieve a high degree of activation with essentially no change in concentration profile. The selection of the proper laser annealing parameters is optimized by observation of the reduction of sheet resistance and concentration profile as measured on a test site. Application of the method is applied to forming a MOS FET and a CMOS device. The additional processing steps required by the invention are applied simultaneously to both n-channel and p-channel devices of the CMOS device pair.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

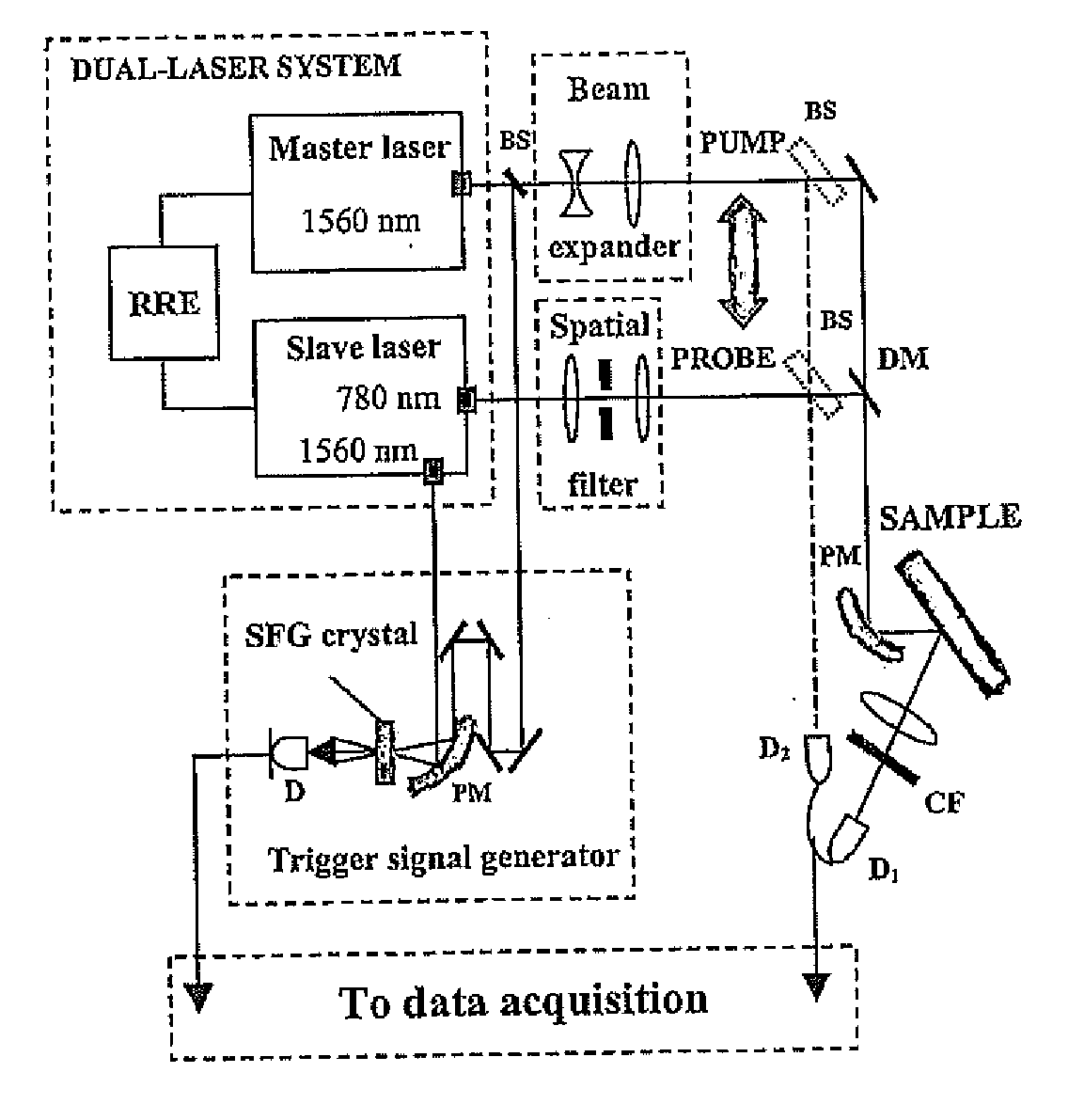

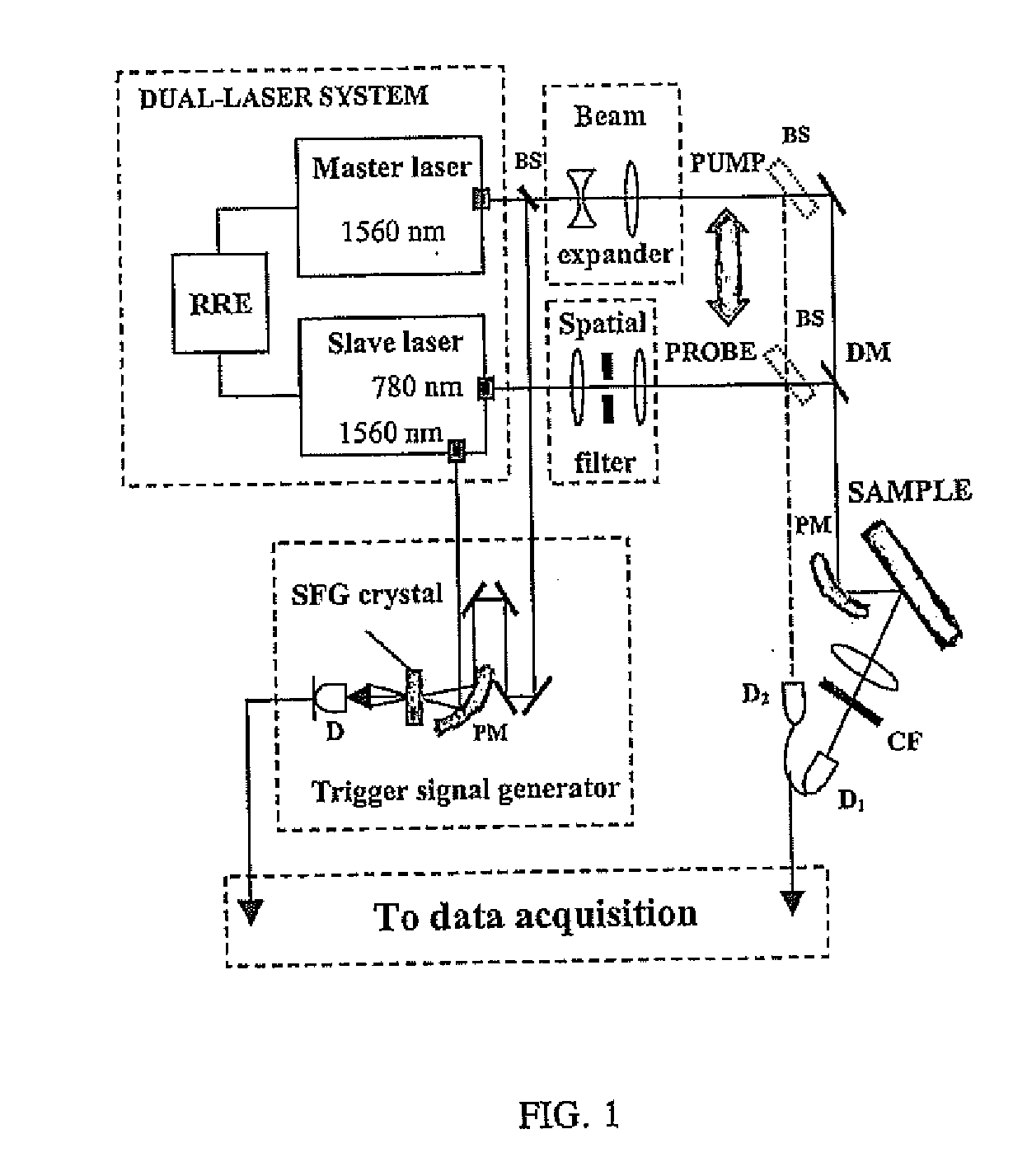

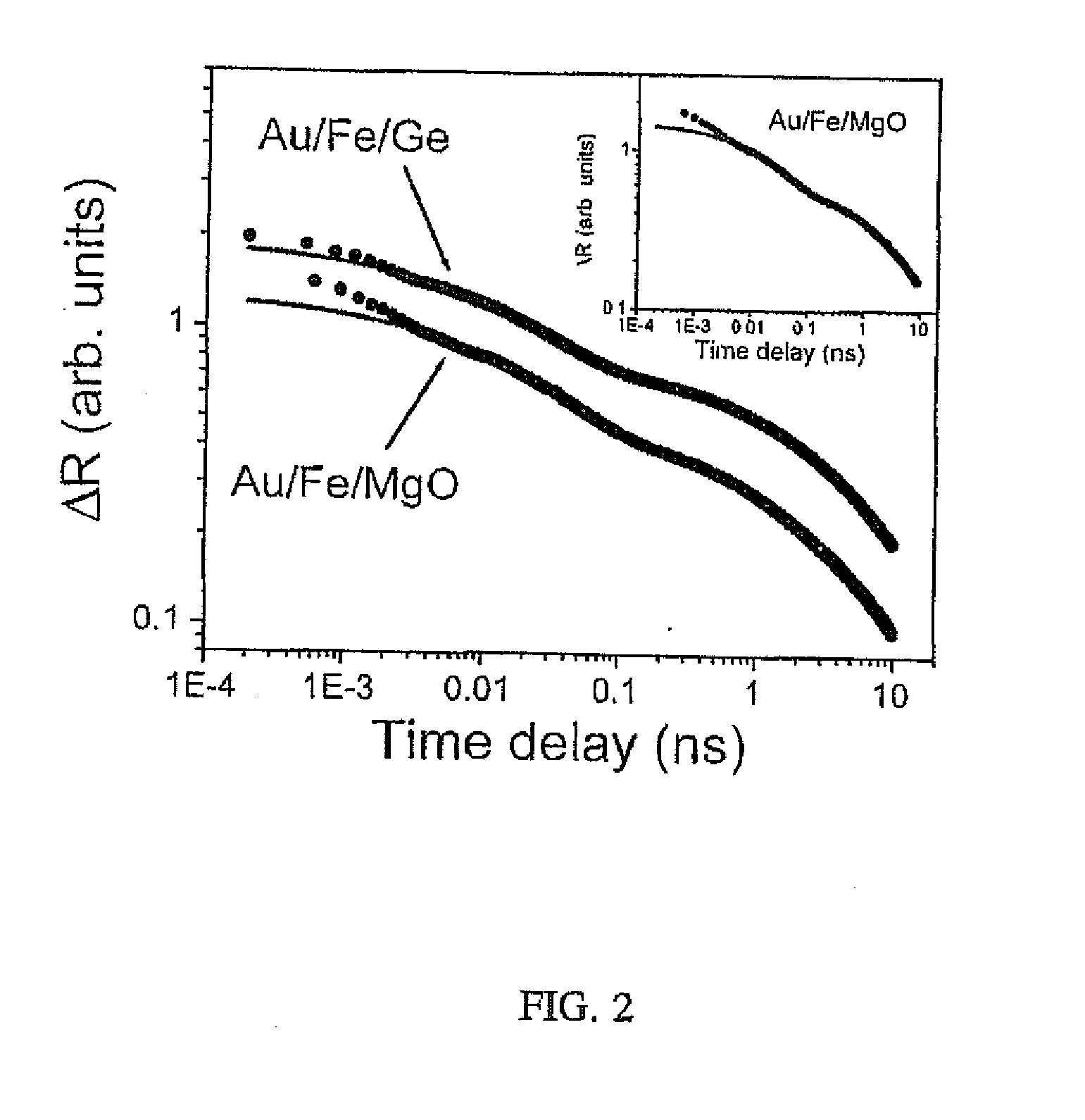

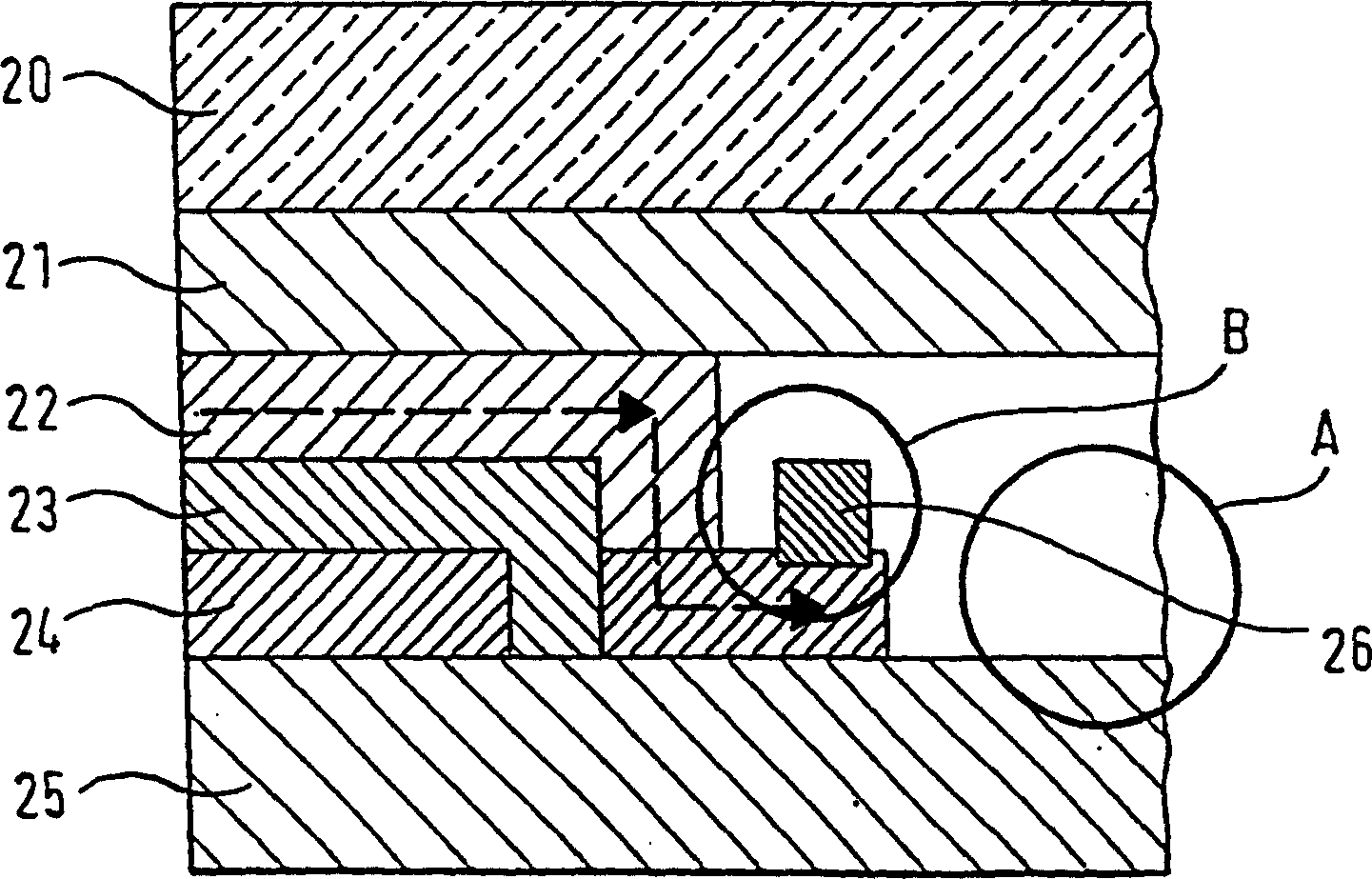

Method and system for measuring at least one property including a magnetic property of a material using pulsed laser sources

ActiveUS20090212769A1Efficient and sensitiveUsing optical meansMagnetic field measurement using magneto-optic devicesLength wavePulse sequence

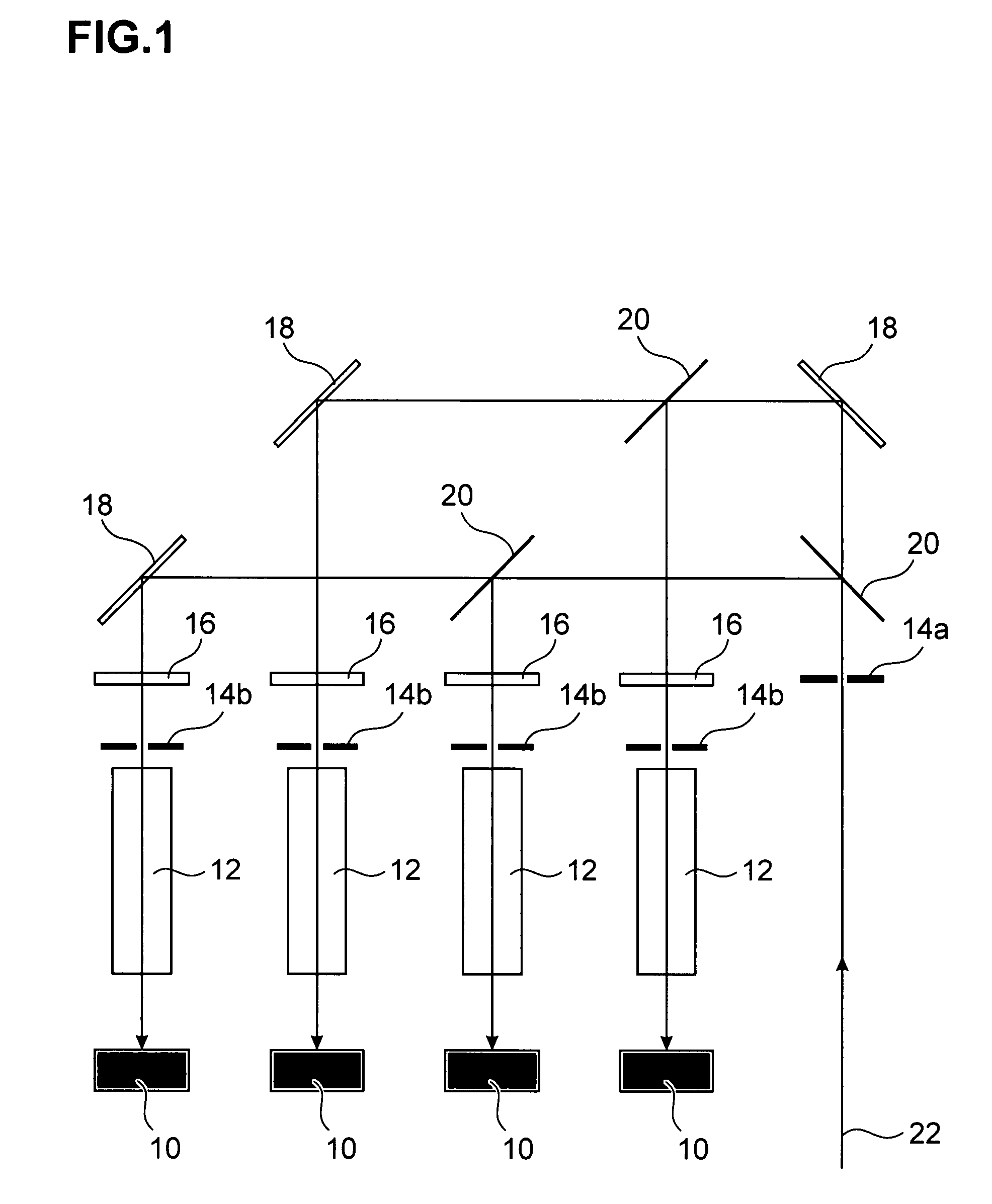

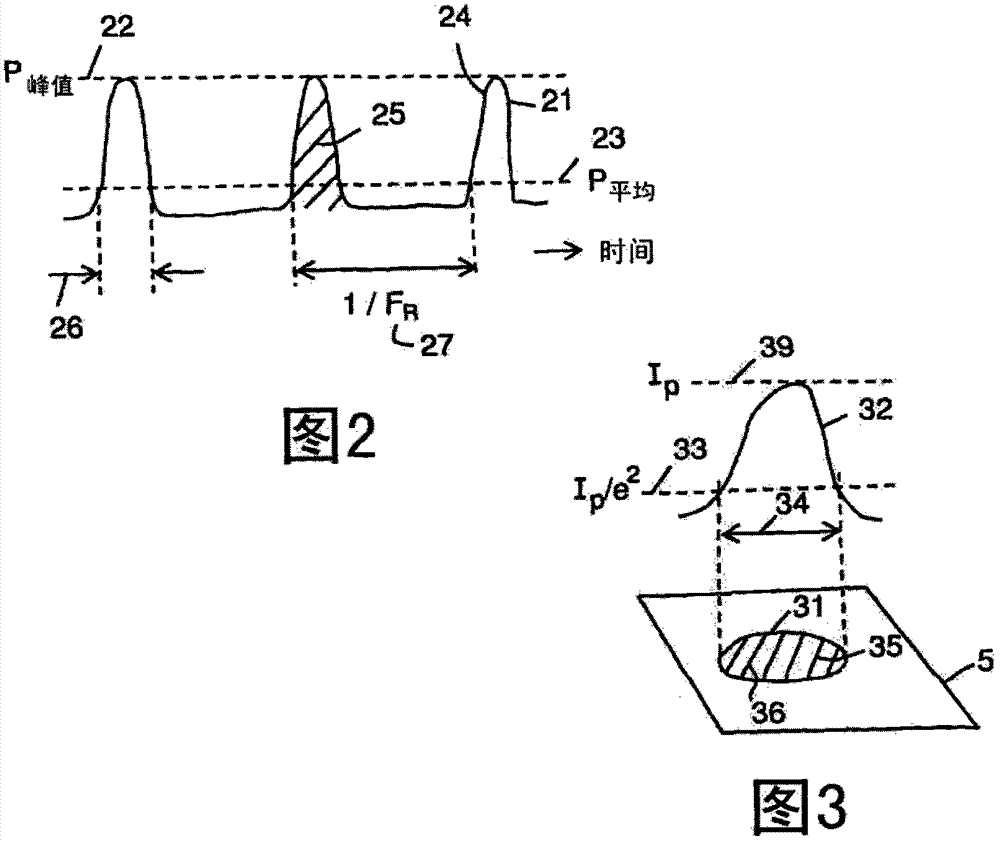

A method of measuring at least one property including a magnetic property of target material is provided. The method includes the step of generating a pump pulse train having one or more pump pulses at a repetition rate along a first propagation path, each pump pulse having a pulse energy density, a laser wavelength within a range of laser wavelengths, and a pulse duration The method further includes the step of irradiating the target material with at least a portion of the one or more pump pulses focused into at least one spot having a spot shape and size so as to cause transient perturbation in the target material. The method still further includes the step of generating at least one probe pulse train having one or more probe pulses at a repetition rate along a second propagation path, each probe pulse having a pulse energy density, a laser wavelength within a range of laser wavelengths, and a pulse duration. The method further includes the step of irradiating the target material with at least a portion of the one or more probe pulses focused into at least one spot having a spot shape and size to obtain one or more reflected probe pulses which are modulated based on the transient perturbation. The method still further includes the step of electronically controlling a time interval between a time at which the target material is irradiated by each of the focused pump pulses and a time at which the target material is irradiated by each of its corresponding focused probe pulses. The method further includes the step of detecting each modulated probe pulse to obtain one or more corresponding signals. The method still further includes the step of processing the one or more signals to obtain one or more measurement signals which represents the at least one property including the magnetic property of the target material.

Owner:RGT UNIV OF MICHIGAN

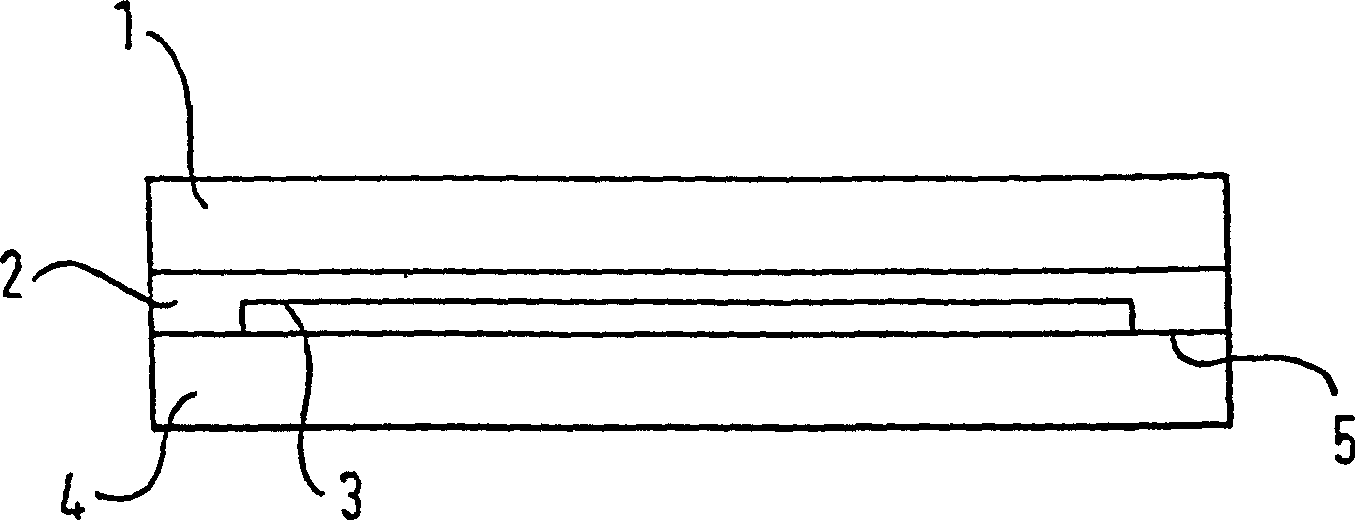

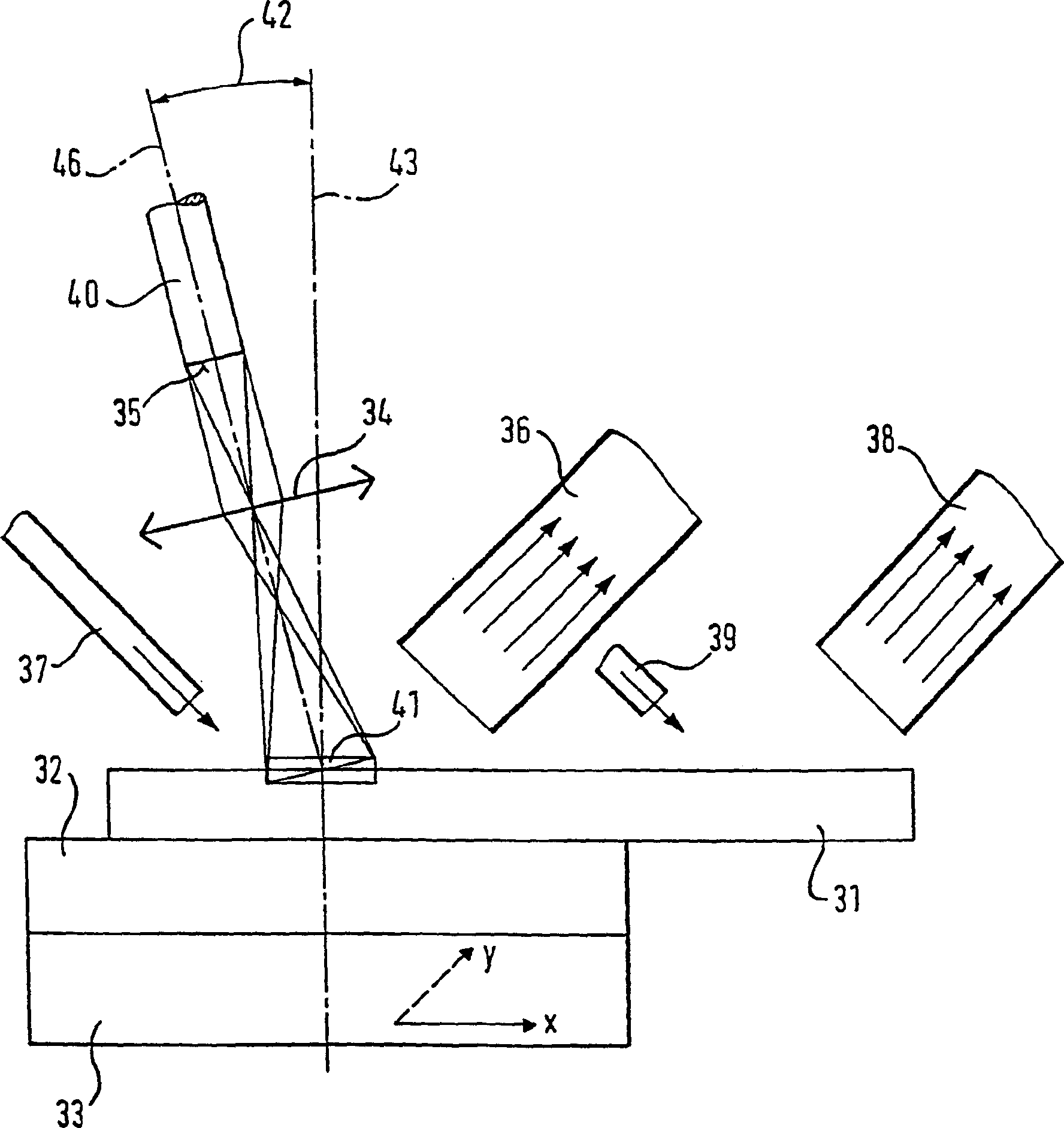

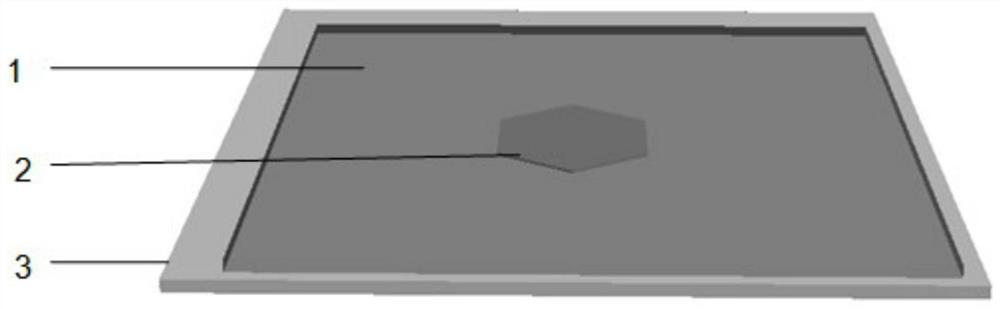

Program-controlled dicing of a substrate using a pulsed laser

InactiveUS20050236378A1Facilitate dicing of the substrateControl damageSemiconductor/solid-state device manufacturingPrinted circuit manufactureChemical reactionLaser cutting

A substrate (30) is diced using a program-controlled pulsed laser beam (35) apparatus having an associated memory for storing a laser cutting strategy file. The file contains selected combinations of pulse rate Δt, pulse energy density E and pulse spatial overlap to machine a single layer or different types of material in different layers (31, 32, 33, 34) of the substrate while restricting damage to the layers and maximising machining rate to produce die having predetermined die strength and yield. The file also contains data relating to the number of scans necessary using a selected combination to cut through a corresponding layer. The substrate is diced using the selected combinations. Gas handling equipment for inert or active gas may be provided for preventing or inducing chemical reactions at the substrate prior to, during or after dicing.

Owner:XSIL TECH

Program controlled dicing of a substrate using a pulsed laser beam

InactiveUS20110029124A1Maximizing machiningFacilitate dicing of the substrateSemiconductor/solid-state device manufacturingElectric programme controlChemical reactionLight beam

A substrate is diced using a program-controlled pulsed laser beam apparatus having an associated memory for storing a laser cutting strategy file. The file contains selected combinations of pulse rate Δt, pulse energy density E and pulse spatial overlap to machine a single layer or different types of material in different layers of the substrate while restricting damage to the layers and maximising machining rate to produce die having predetermined die strength and yield. The file also contains data relating to the number of scans necessary using a selected combination to cut through a corresponding layer. The substrate is diced using the selected combinations. Gas handling equipment for inert or active gas may be provided for preventing or inducing chemical reactions at the substrate prior to, during or after dicing.

Owner:ELECTRO SCI IND INC

Methods for fabricating memory devices

InactiveUS6410412B1Increase energy densitySolve the small densityTransistorNanoinformaticsPulse energy densitySemiconductor

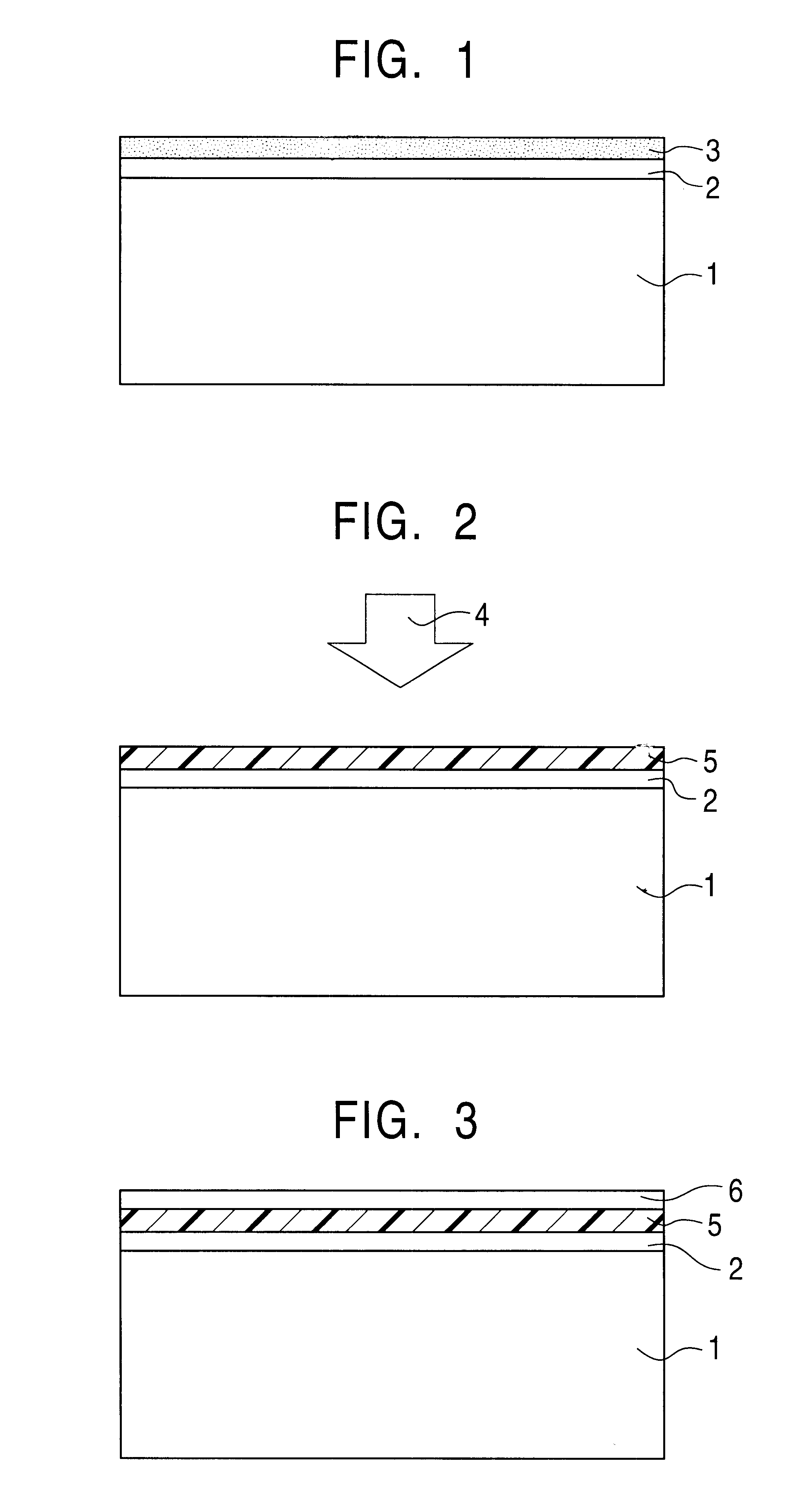

Methods for fabricating memory devices having a multi-dot floating gate ensuring a desirable crystallization of a semiconductor film without ruining the flatness of the surface of the polycrystallized silicon layer and a tunnel oxide film, allowing desirable semiconductor dots to be produced, and allowing production of the memory devices having a multi-dot floating gate with ease and at low costs even when a substrate is made of glass or plastic. Such a method for fabricating memory devices includes steps for forming on a substrate a semiconductor film and treating said semiconductor film by a first laser annealing so as to have a polycrystalline structure; forming on the semiconductor film a semiconductor dot forming film having a non-stoichiometric composition with an excessive content of a semiconductor element; and dispersing semiconductor dots within the semiconductor dot forming film by a second laser annealing thereby to produce semiconductor dots; in which a pulse energy density of the laser used for the first laser annealing is larger than a pulse energy density of the laser used for the second laser annealing.

Owner:SONY CORP

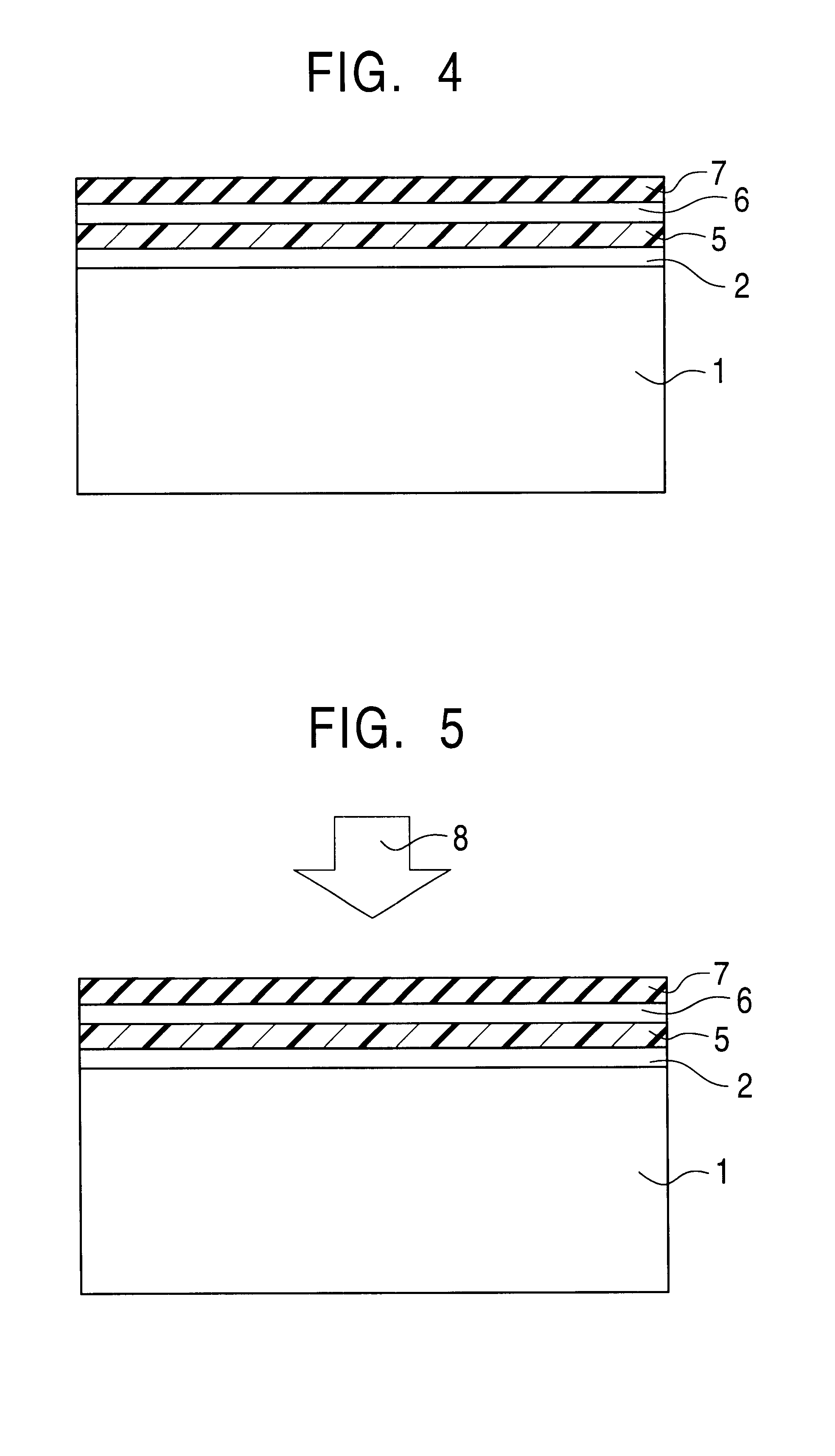

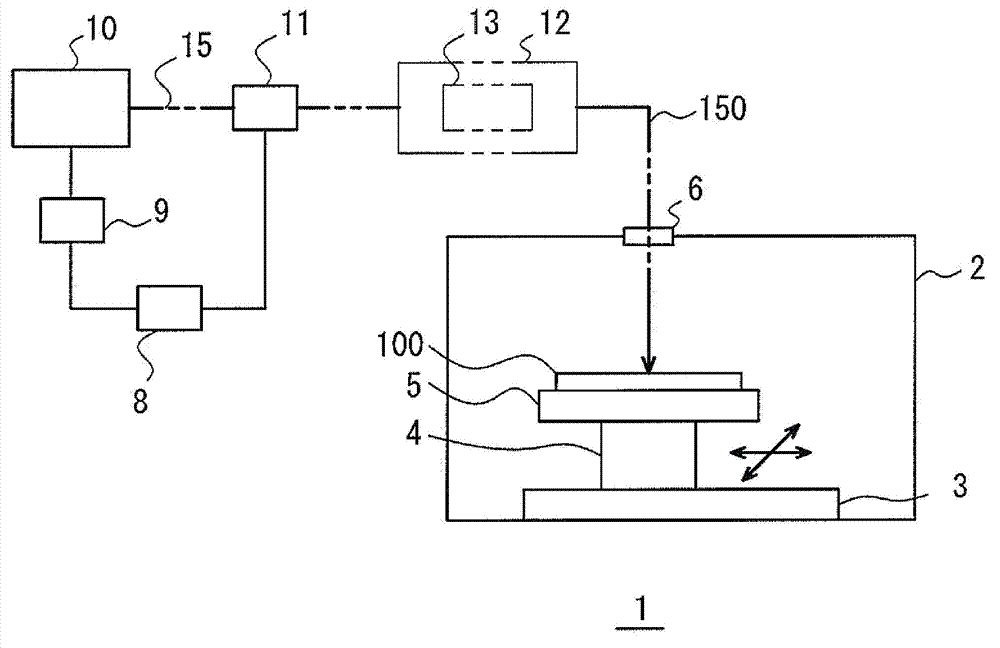

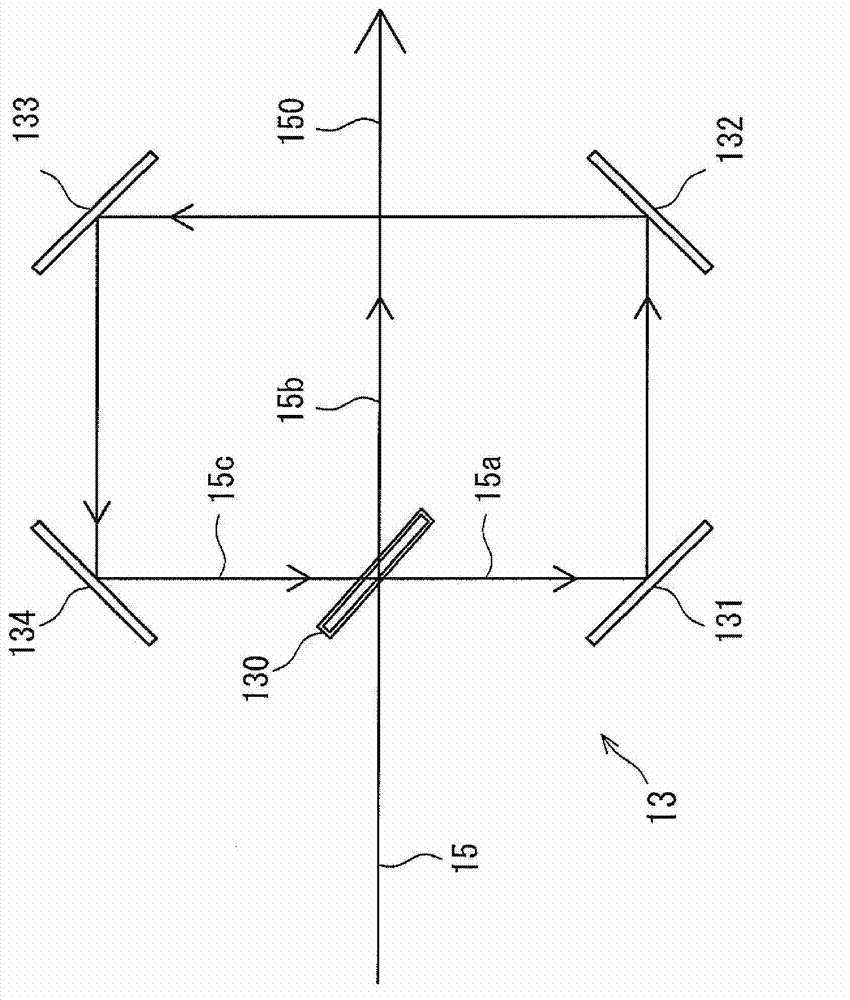

Laser processing system and method

ActiveCN106938370AIncrease profitImprove real-time performanceMetal working apparatusLaser beam welding apparatusLaser processingOptoelectronics

The invention discloses a laser processing system and method. The laser processing system comprises a laser machine, an optical system, a sensor, a processor and a controller, wherein the laser machine is used for providing laser needed for processing, the optical system is arranged above a workpiece table and is used for adjusting the size of a laser spot, and projecting the adjusted laser spot onto the workpiece table, the sensor is arranged above the workpiece table and is used for collecting parameter information of workpiece material, the processor is connected with the sensor and is used for receiving and processing the parameter information acquired by the sensor to obtain the size of the laser spot needed by the workpiece material, and the controller is connected with the processor and is used for receiving the information of the processor to control the optical system. According to the laser processing system, the parameter information of the workpiece material is collected in real time through the sensor, the required size of the laser spot is calculated through the processor, the laser pulse energy density is adjusted in real time by adopting the controller to control the optical system to change the size of the laser spot, so that the real-time performance is good, and the cutting efficiency is high; and in the cutting process, the laser machine outputs lasers at the rated laser power all the time, and the utilization rate of laser energy is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Optical synthetic quartz glass and method for producing the same

ActiveUS7312170B2Increase resistanceHigh bond energyGlass shaping apparatusOptical light guidesHydrogenHydrolysis

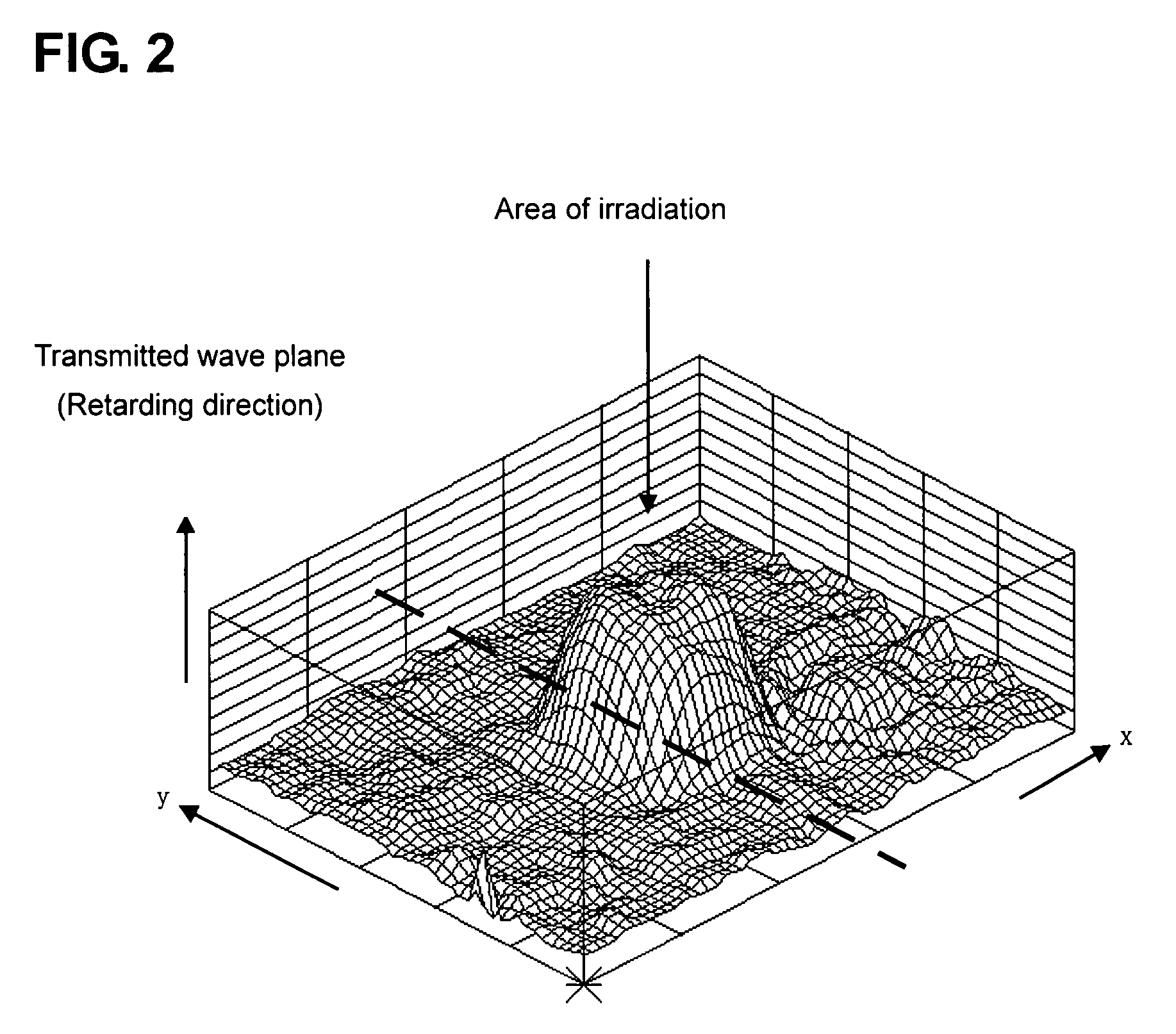

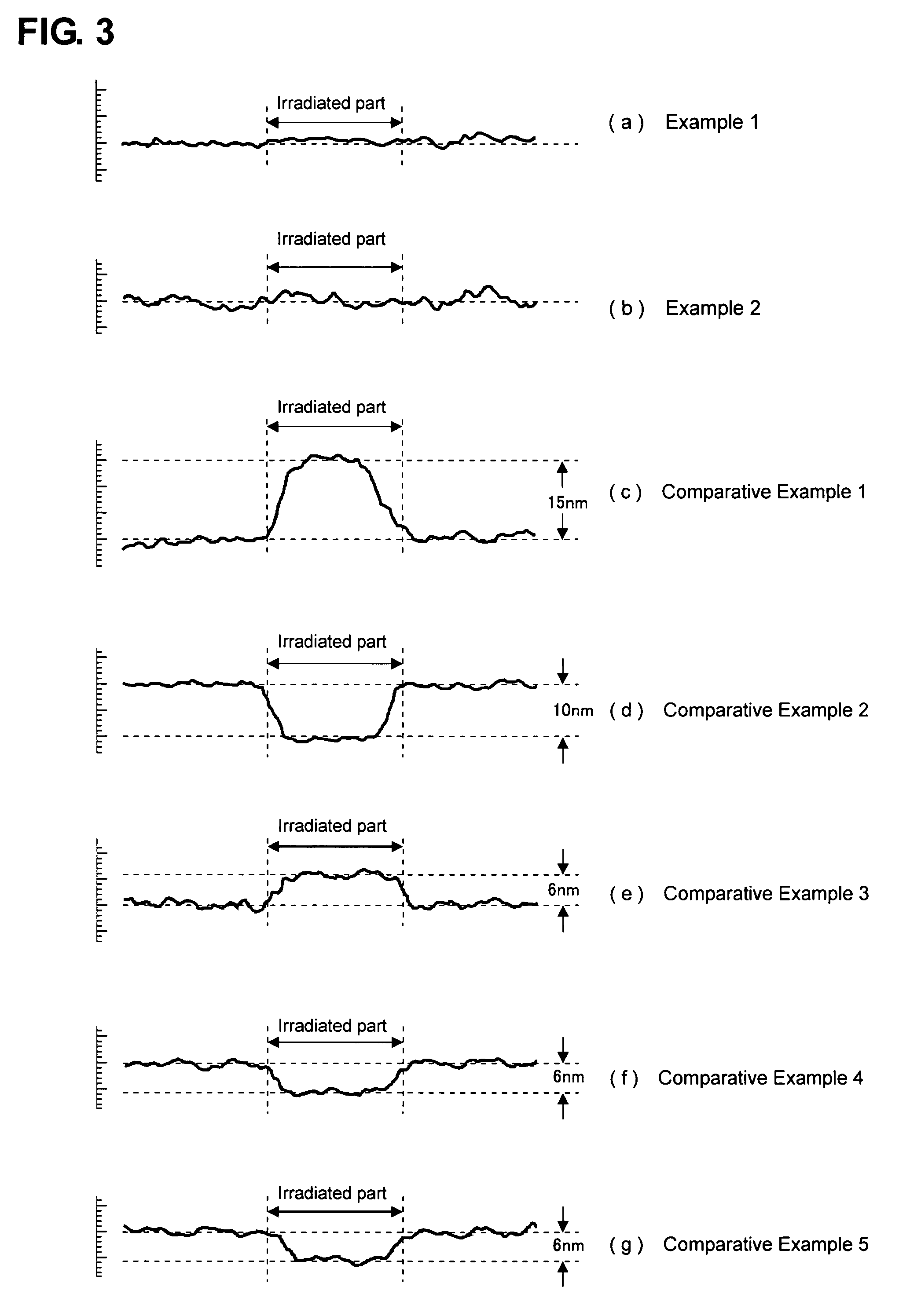

The present invention provides an optical synthetic quartz glass material which substantially does not cause changes in transmitted wave surface (TWS) by solarization, compaction (TWS delayed), rarefaction (TWS progressed) and photorefractive effect when ArF excimer laser irradiation is applied at a low energy density, e.g. at energy density per pulse of 0.3 mJ / cm2 or less. The present invention further provides a method for manufacturing the same. In order to solve the above-mentioned problems, the optical synthetic quartz glass material of the present invention is characterized in that, in a synthetic quartz glass prepared by a flame hydrolysis method using a silicon compound as a material, the followings are satisfied that the amount of SiOH is within a range of more than 10 ppm by weight to 400 ppm by weight, content of fluorine is 30 to 1000 ppm by weight, content of hydrogen is 0.1×1017 to 10×1017 molecules / cm3 and, when the amounts of SiOH and fluorine are A and B, respectively, total amount of A and B is 100 ppm by weight or more and B / A is 0.25 to 25.

Owner:HERAEUS QUARZGLAS +1

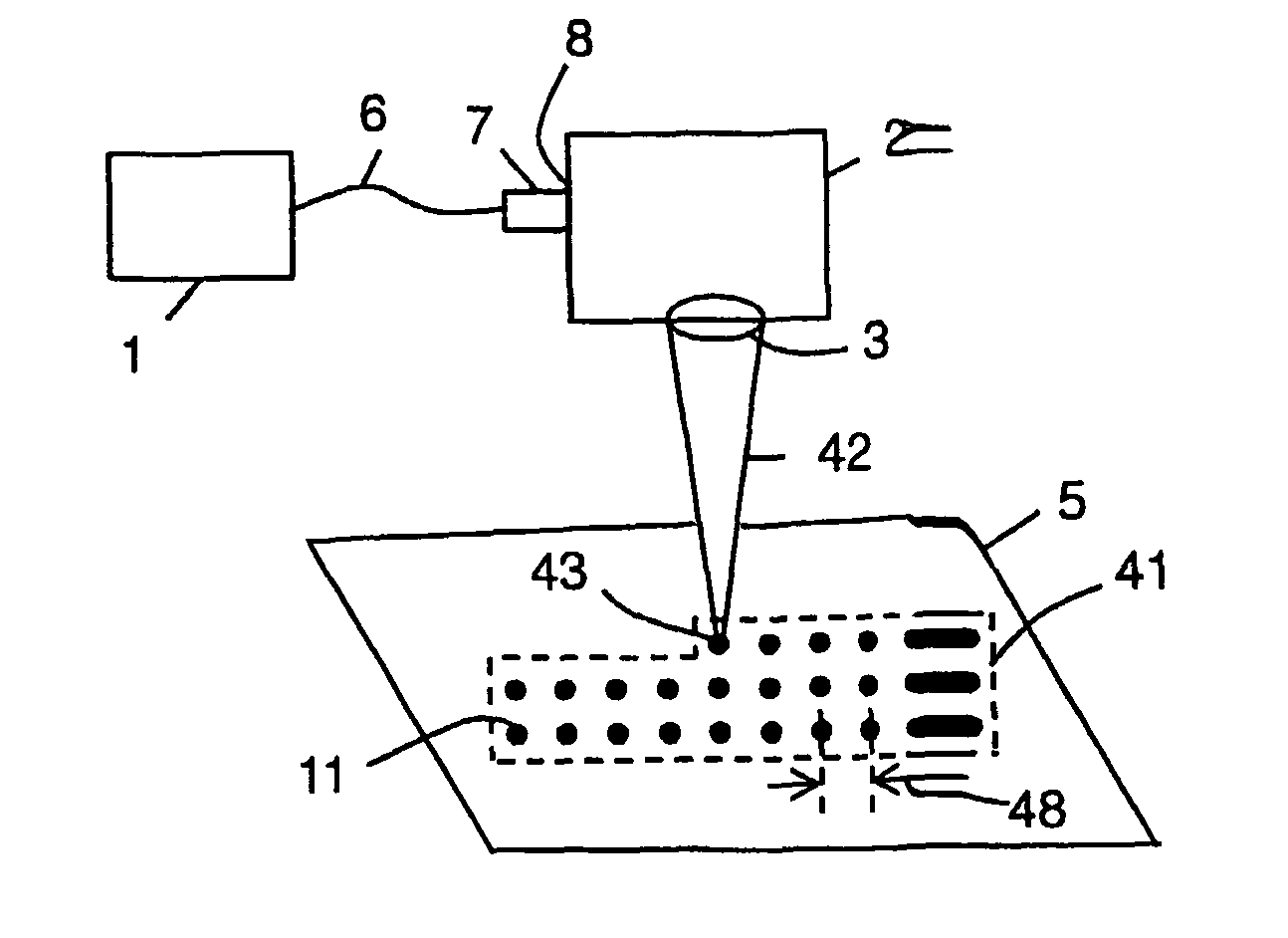

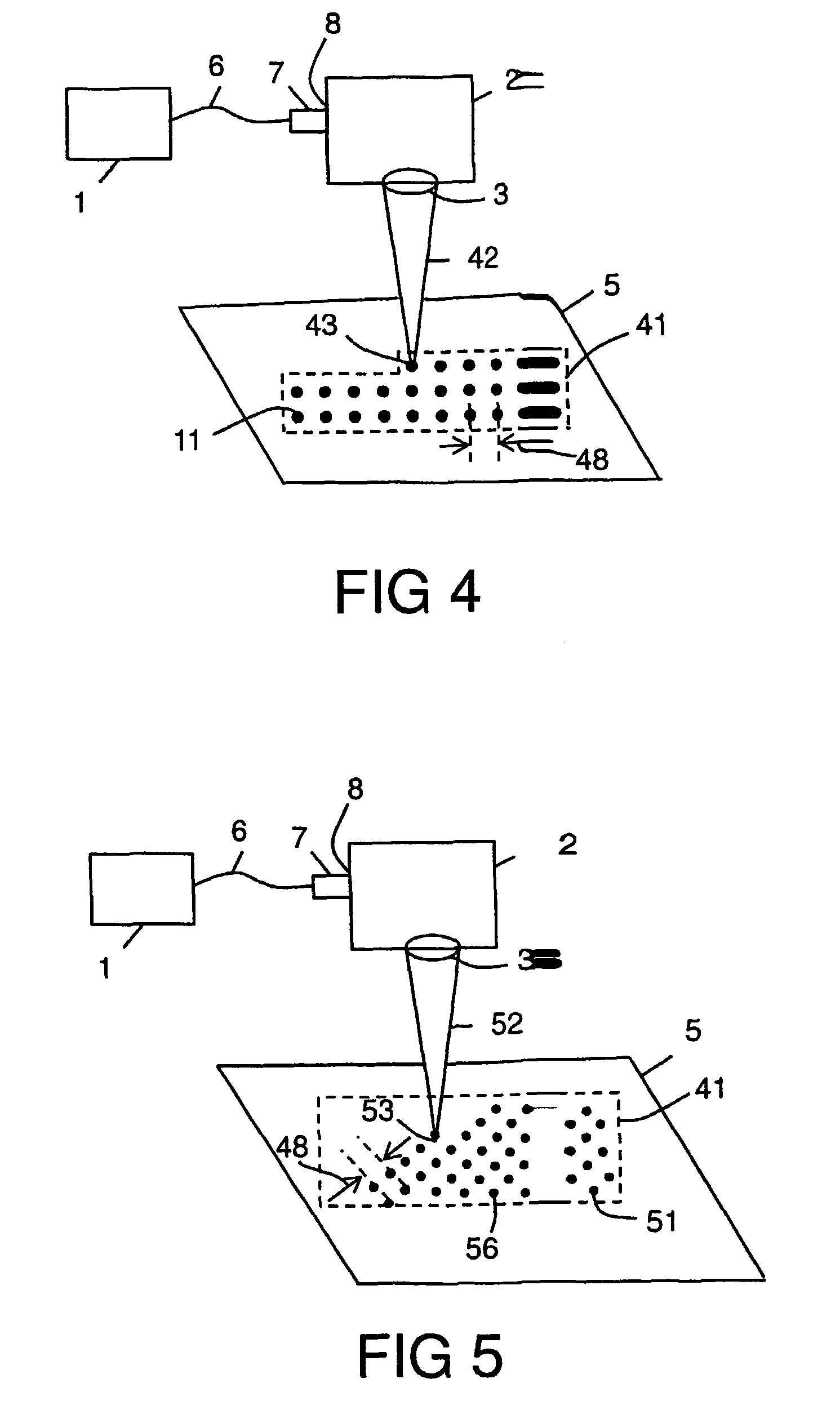

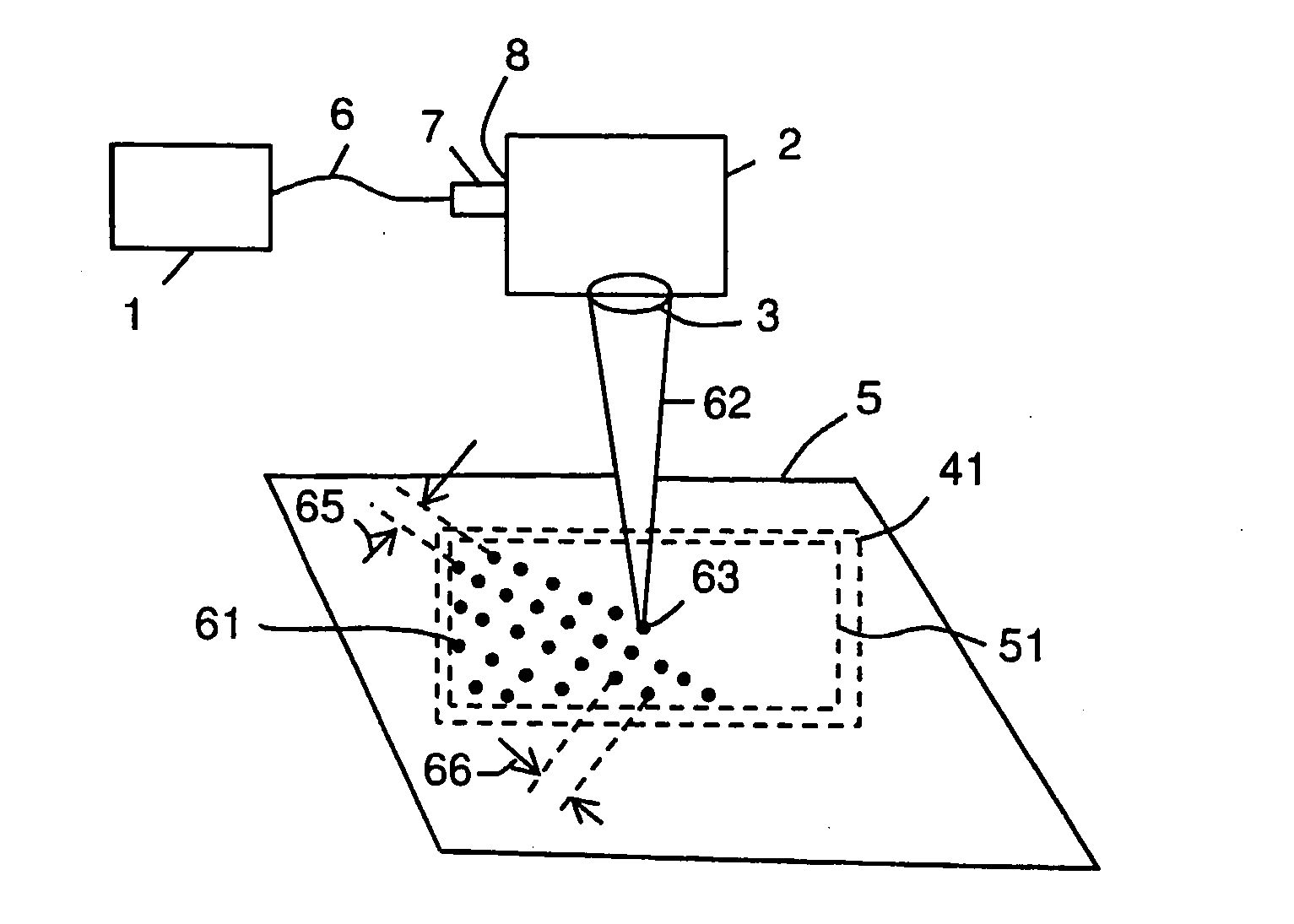

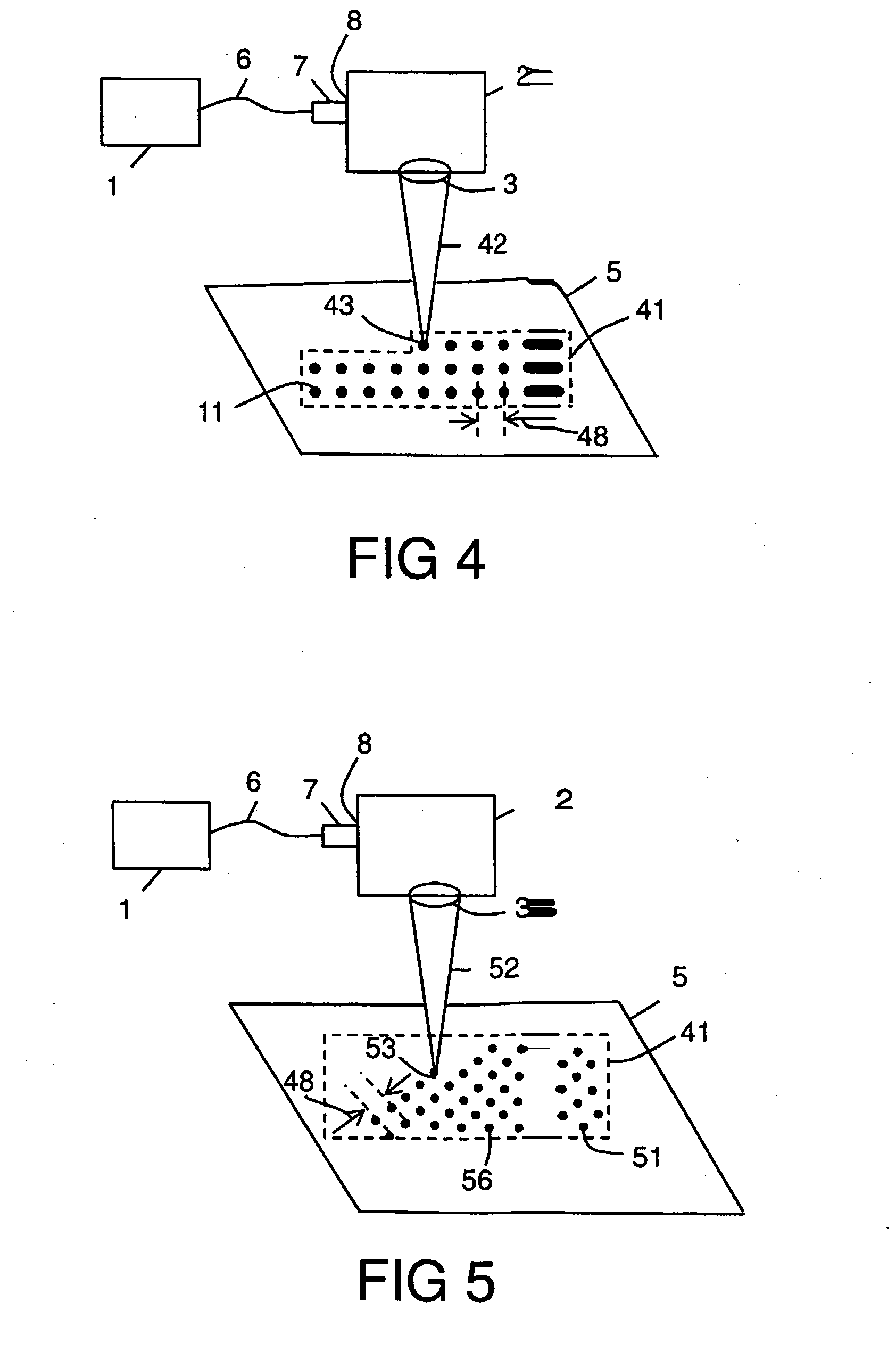

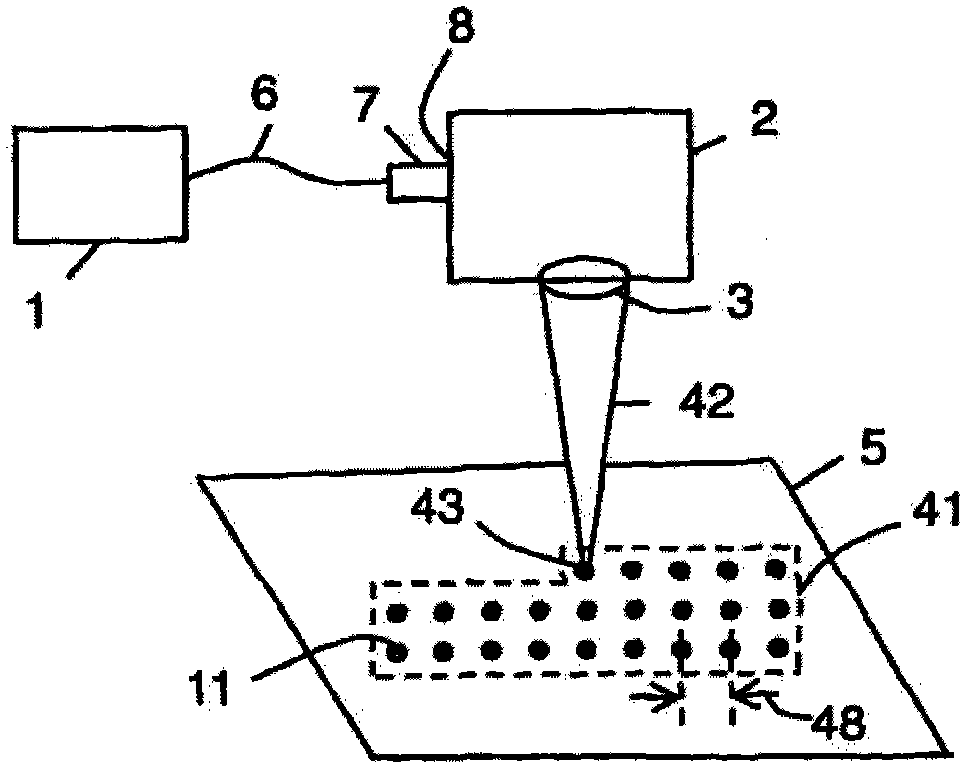

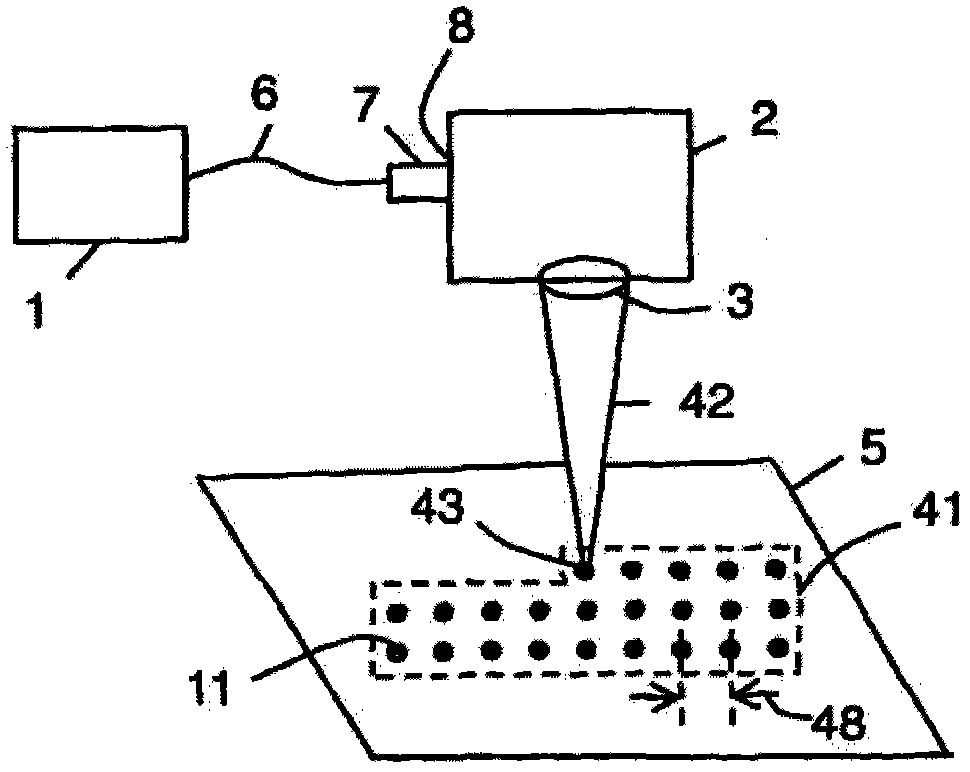

Method for laser marking a metal surface with a desired colour

A method for laser marking a metal surface (5) with a desired color, which method comprises forming at least one first pattern (41) on the metal surface (5) with a first laser beam (42) having a first pulse fluence (43), forming at least one second pattern (51) on the metal surface with a second laser beam (52) having a second pulse fluence (53), characterized by causing the second pattern (51) to overlay the first pattern (41), arranging the first pulse fluence (43) to be at least five times greater than the second pulse fluence (53), the color being given by the first and second pulse fluences (43, 53) and spot spacings (48) in the first and second patterns (41, 51), and selecting the first and second pulse fluences (43, 53) and the spot spacings (48) to form the desired color.

Owner:SPI LASERS UK

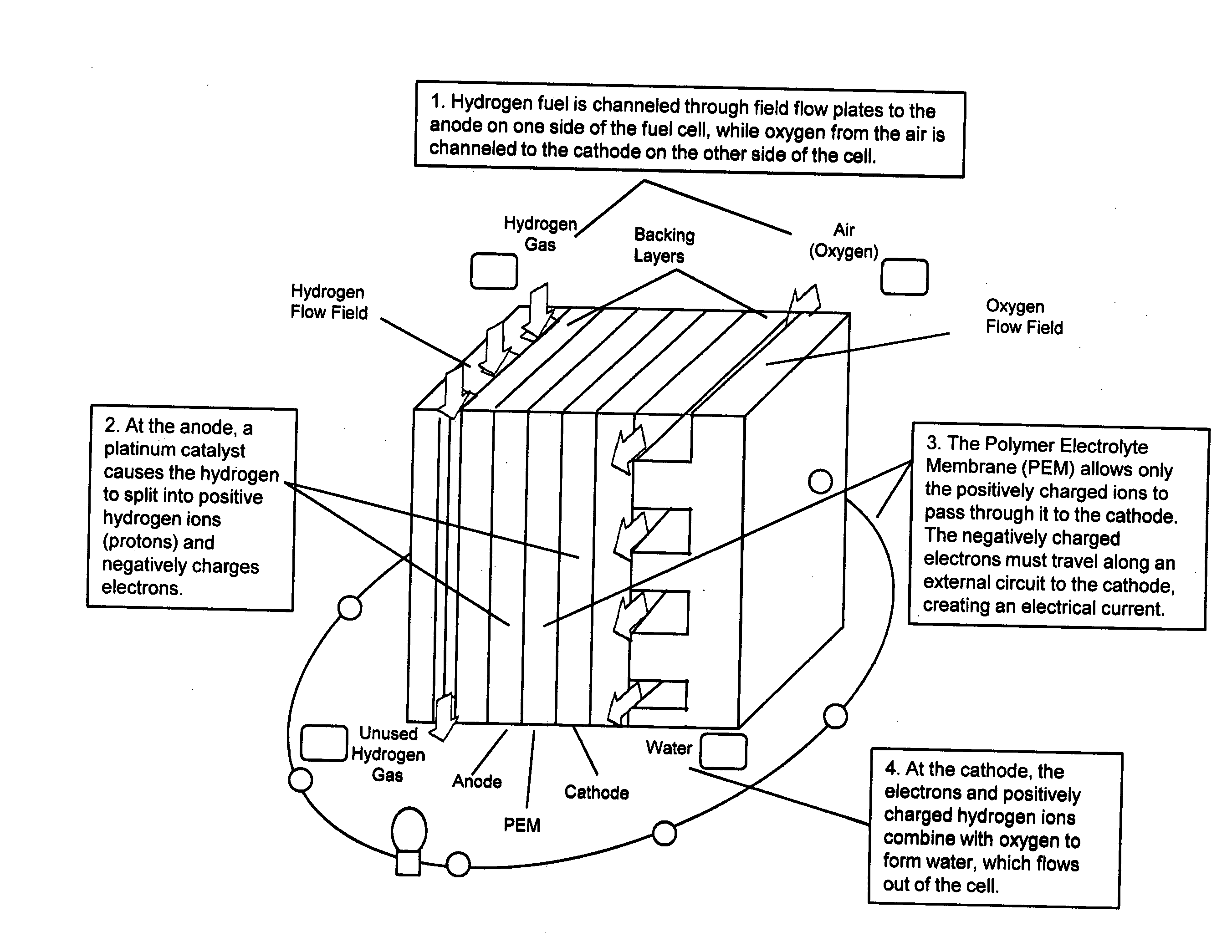

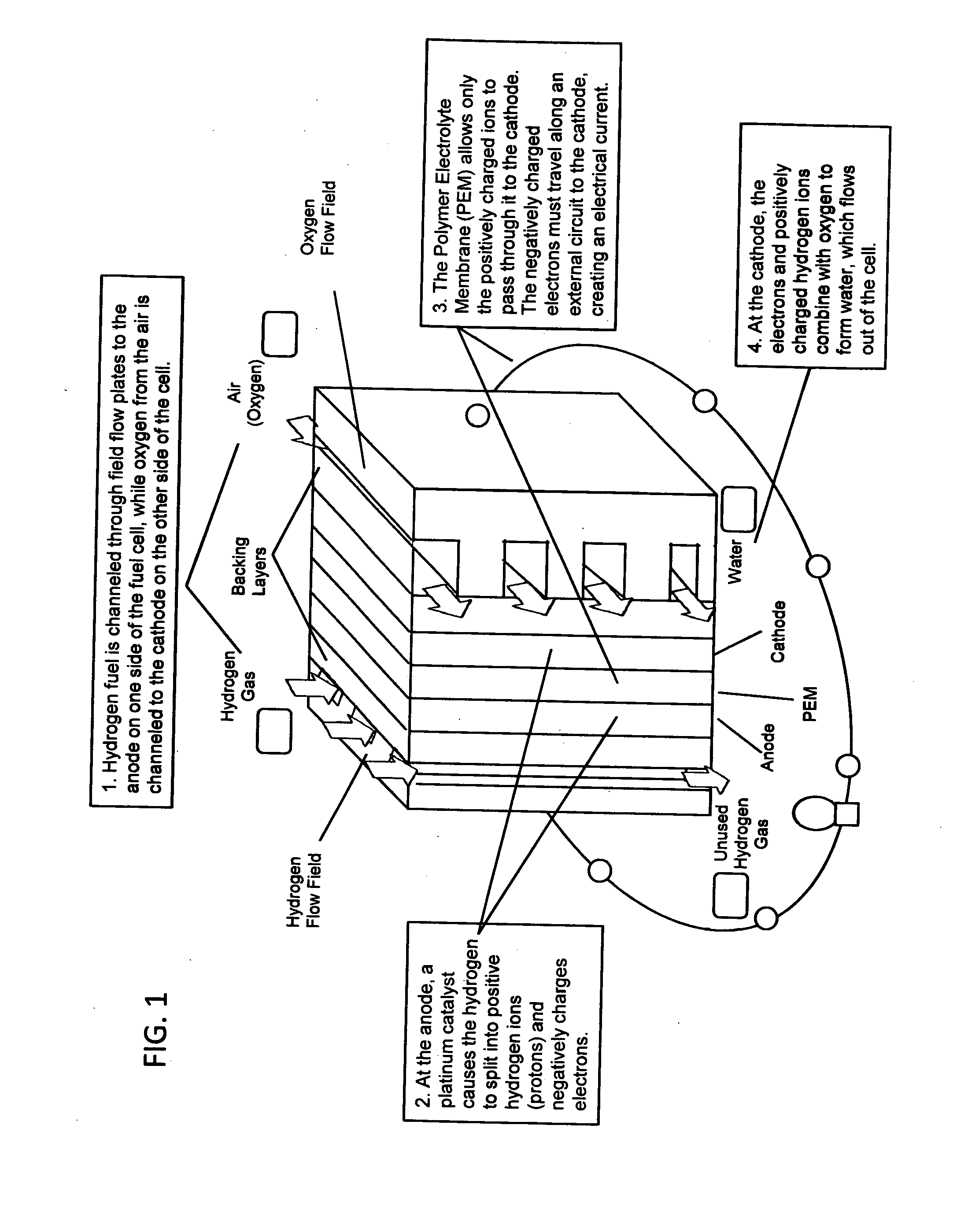

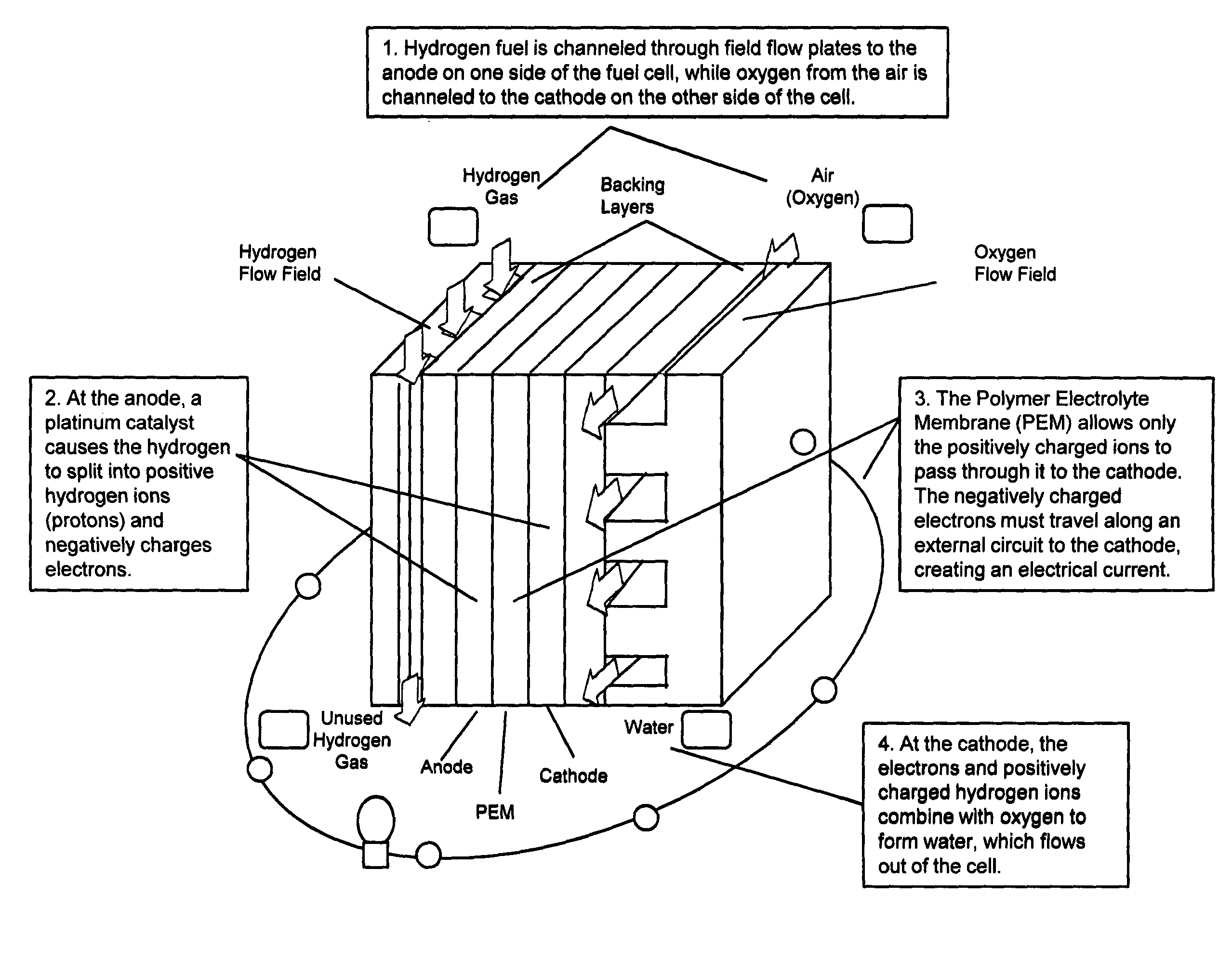

Hollow glass microsphere candidates for reversible hydrogen storage, particularly for vehicular applications

InactiveUS20090242382A1Increase fuel cell system efficiencyHigh realizable packing densityReversible hydrogen uptakeOther chemical processesInitial permeabilityMicrosphere

A source of hydrogen is a glass or glass-ceramic shell and a gas comprising at least 80% by volume of hydrogen. The glass shell has an initial permeability to hydrogen gas of less than about 50% decrease in pressure in 30 days and a final permeability to hydrogen of about 50% decrease in pressure in a few minutes or less, upon exposure of the glass to a continuous or pulsed fluence of at least 0.1 W / cm2 of electromagnetic radiation to modulate the microstructure of the glass and to increase the hydrogen gas permeability of the glass network. A method of providing hydrogen gas in the shell and exposing the shell to electromagnetic radiation of a wavelength and fluence that increases permeability of the shell to hydrogen gas so that encapsulated hydrogen gas permeates through the shell.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION OF BEHALF OF THE UNIV OF NEVADA LAS VEGAS THE

Method for Laser Marking a Metal Surface with a Desired Colour

A method for laser marking a metal surface (5) with a desired colour, which method comprises forming at least one first pattern (41) on the metal surface (5) with a first laser beam (42) having a first pulse fluence (43), forming at least one second pattern (51) on the metal surface with a second laser beam (52) having a second pulse fluence (53), characterized by causing the second pattern (51) to overlay the first pattern (41), arranging the first pulse fluence (43) to be at least five times greater than the second pulse fluence (53), the colour being given by the first and second pulse fluences (43, 53) and spot spacings (48) in the first and second patterns (41, 51), and selecting the first and second pulse fluences (43, 53) and the spot spacings (48) to form the desired colour.

Owner:SPI LASERS UK

Femtosecond laser amorphism fine machining method for amorphous alloy

InactiveCN1966203AShort durationHigh peak powerOther manufacturing equipments/toolsLaser beam welding apparatusAmorphismOptoelectronics

The invention relates to a non-crystal fine processing method which uses femtosecond laser to process non-crystal alloy, wherein said method uses femtosecond laser to make hole, etch, and cut the non-crystal alloy, while the impulse energy density of femtosecond laser is 50-100H / cm2 and the impulse width is 45-100fs in holing; the impulse energy density is 3-15J / cm2, the impulse width is 45-100fs, and the scanning speed is 100-200 mum / s in etching line; the impulse energy density is 75-110J / cm2, the impulse width is 45-100fs, and the scanning speed is 100-200 mum / s in cutting. The invention can realize sub-micron processing accuracy, without crystallization in etching area.

Owner:HUAZHONG UNIV OF SCI & TECH

Via hole forming method

InactiveUS20080009132A1Efficiently formedWithout producing metal contaminantSemiconductor/solid-state device detailsSolid-state devicesDevice formOptoelectronics

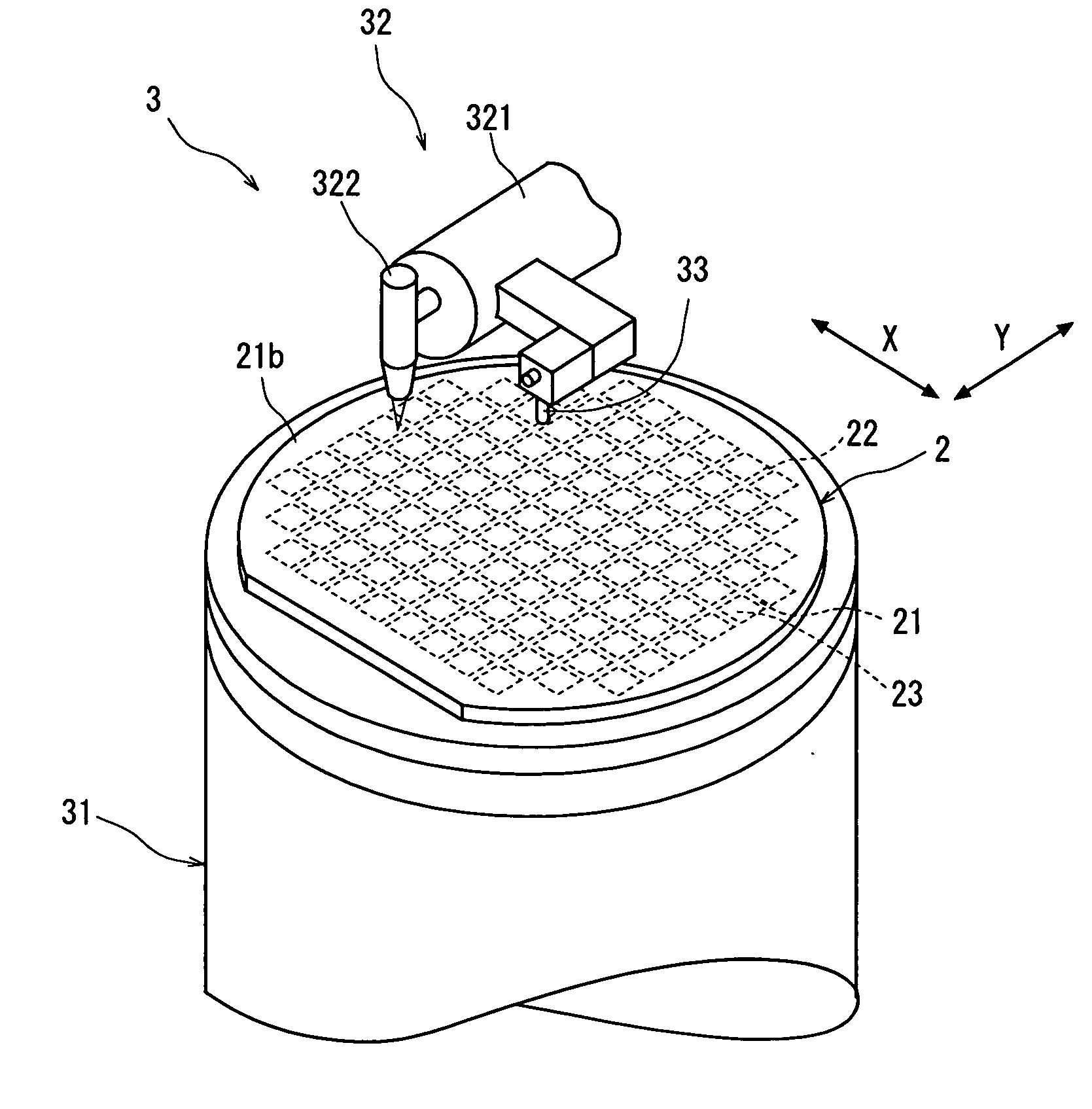

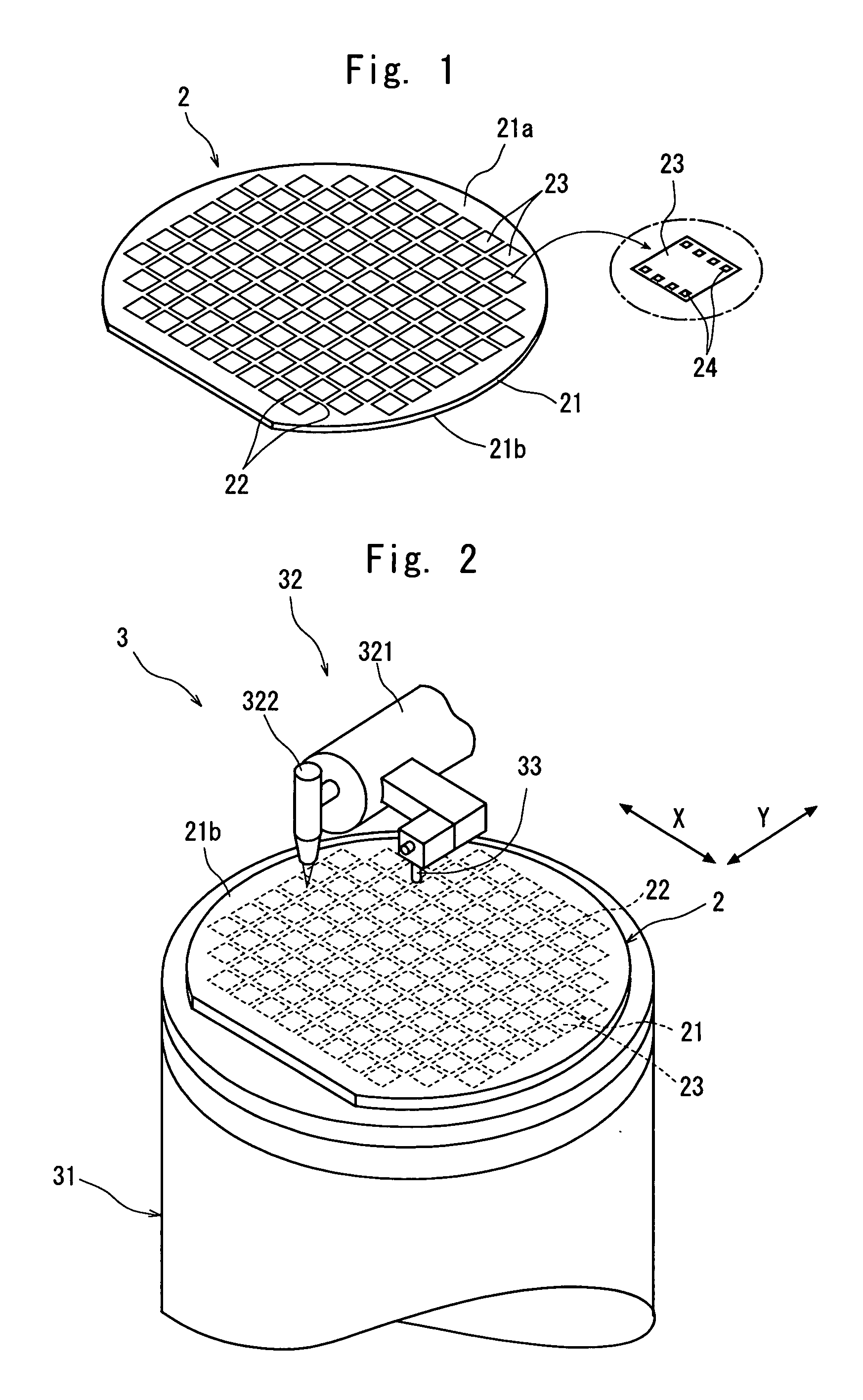

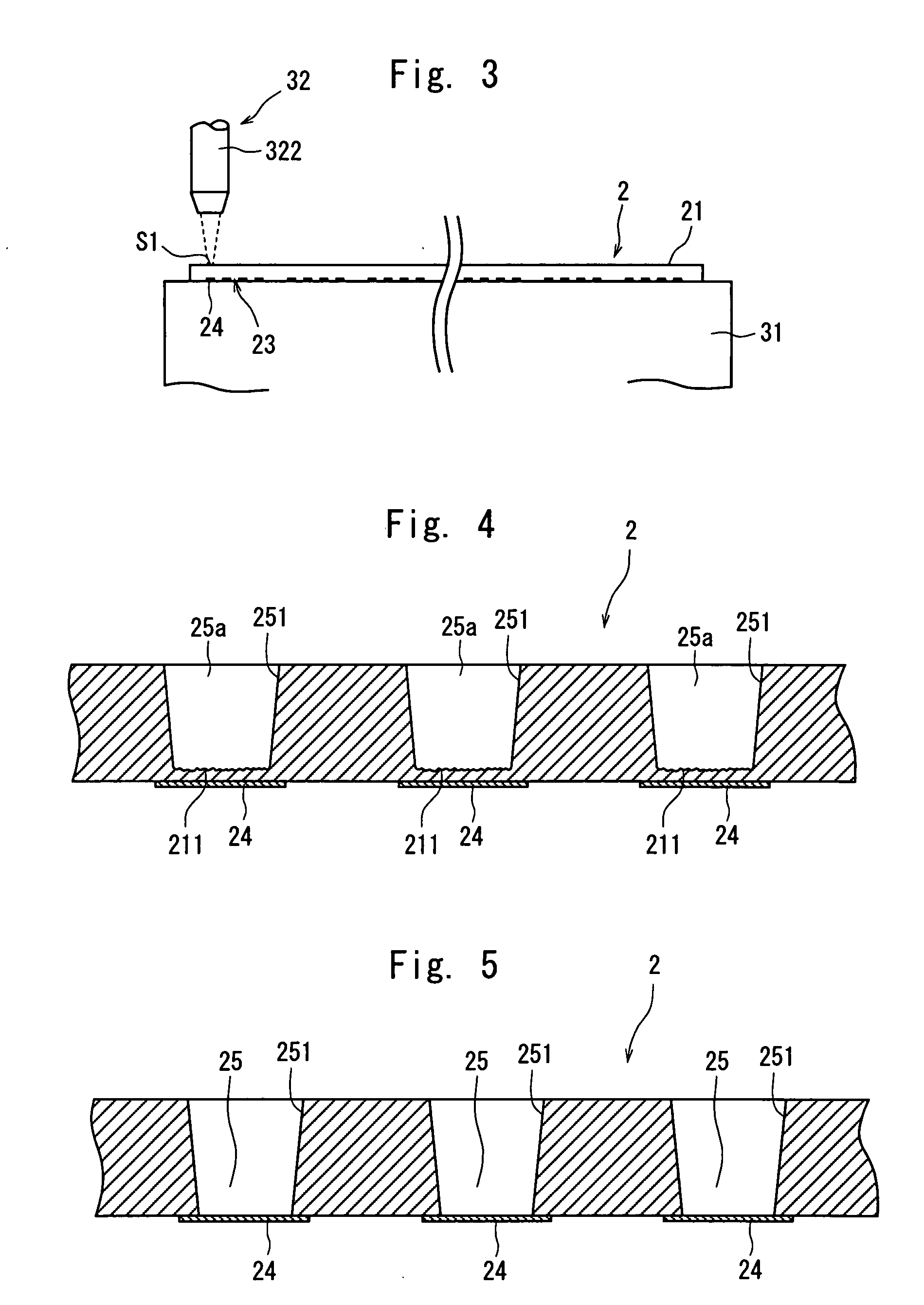

A method of forming a via hole reaching a bonding pad in a wafer having a plurality of devices formed on the front surface of a substrate and bonding pads formed on each of the devices by applying a pulse laser beam to the rear surface of the substrate, the method comprising the steps of:forming a non-through hole having a predetermined depth in the front surface of the substrate by applying a pulse laser beam having a spot diameter of 0.75 to 0.9 D when the diameter of the via hole to be formed is represented by D and an energy density per pulse of 40 to 60 J / cm2 to the rear surface of the substrate; andforming a via hole reaching a bonding pad in the substrate by applying a pulse laser beam having an energy density per pulse of 25 to 35 J / cm2 to the hole formed in the substrate.

Owner:DISCO CORP

Method for laser marking metal surface with desired colour

ActiveCN103831534ADuplicating/marking methodsWelding/soldering/cutting articlesPulse energy densityLaser beams

A method for laser marking a metal surface (5) with a desired colour, which comprises forming at least one first pattern (41) on a metal surface (5) with a first laser beam (42) having a first pulse fluence (43), forming at least one second pattern (51) on the metal surface with a second laser beam (52) having a second pulse fluence (53), characterized by causing the second pattern (51) to overlay the first pattern (41), arranging the first pulse fluence (43) to be at least five times greater than the second pulse fluence (53), the colour being given by the first and second pulse fluences (43, 53) and spot spacings (48) in the first and second patterns (41, 51), and selecting the first and second pulse fluences (43, 53) and the spot spacings (48) to form the desired colour.

Owner:SPI LASERS UK

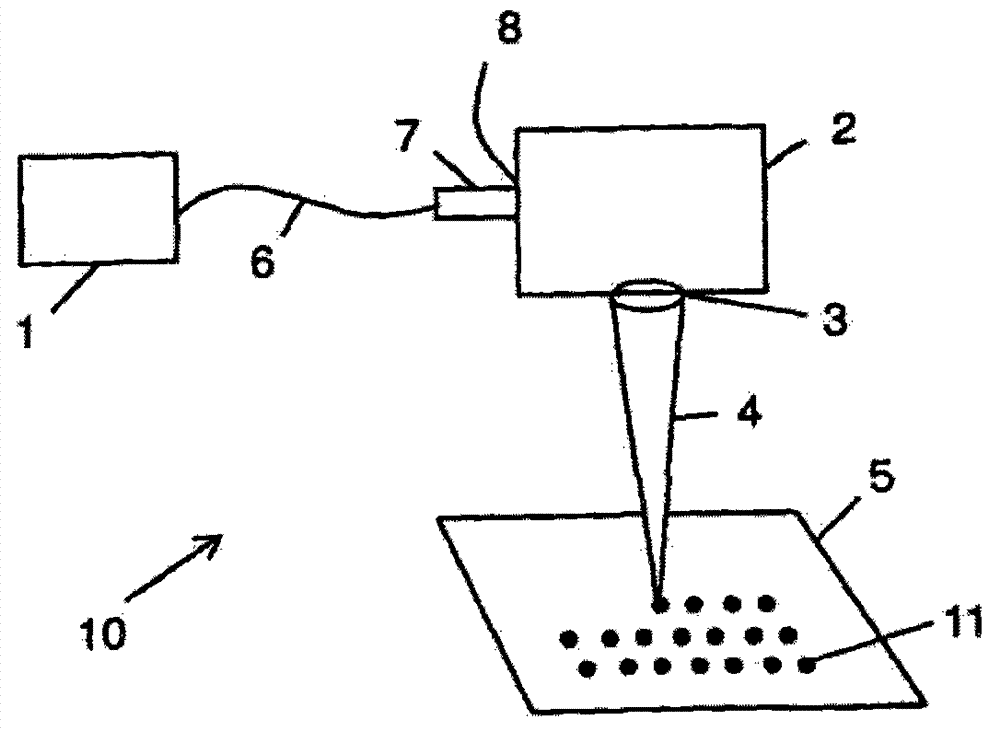

Laser processing method and processing device

Laser beam is irradiated to a surface of a processing target after reforming a cross section of the laser beam with a mask having a pierced hole by concentrating the laser beam passing through the pierced hole by a lens to foreman image of the pierced hole of the mask on the surface of the processing target. The laser beam passing through the lens is scanned to move an irradiating position of the laser beam on the surface of the processing target, and the image of the pierced hole of the mask is formed on the surface of the processing target during the scanning for processing the processing target. A high quality laser process can be carried out.

Owner:SUMITOMO HEAVY IND LTD

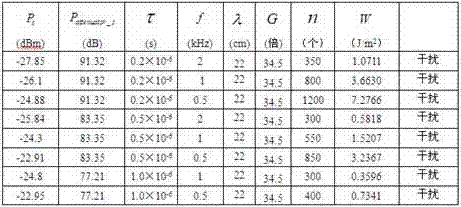

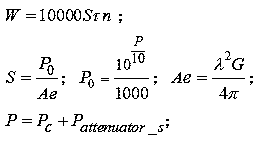

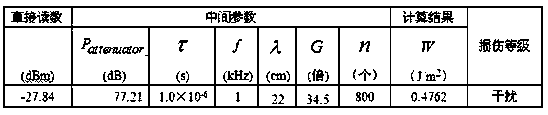

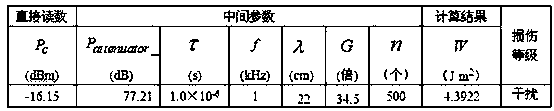

Multiple wave band narrowband high power microwave-based damage effect test method for electroacoustic alarm controller

ActiveCN106959396ASuperiorOverall clarityMeasuring interference from external sourcesMicrowaveX-wave

The invention discloses a multiple wave band narrowband high power microwave-based damage effect test method for an electroacoustic alarm controller. The electroacoustic alarm controller is placed in a test zone, and the method comprises the following steps: in step a1, L wave band high power microwave radiation is set in a system, and the electroacoustic alarm controller faces right to radiation wave waves; in step a2, the electroacoustic alarm controller faces sideways to the radiation wave waves; in step a3, the electroacoustic alarm controller faces in a direction opposite to the radiation waves; in step a4, a polarization mode is changed to a vertical polarization mode; in step a5, a wire cable is hidden in wave absorbing material; in step a6, minimum pulse energy density in steps from step a1 to step a5 is chosen as an interference threshold value for a sample; in step a7, the sample is changed, the steps from step a1 to step a6 are repeated; in step a8, a threshold value range of damage caused on the electroacoustic alarm controller by a wave band high power microwave; in step a9, the microwave radiation system is orderly adjusted to be an S wave band microwave radiation system, a C wave band microwave radiation system and an X wave band microwave radiation system; the test steps from step a1 to step a8 are repeated. The damage effect test method is advantaged by well-organized structure, strong pertinency, easy-to-implement property and the like.

Owner:UNIT 61489 OF PLA

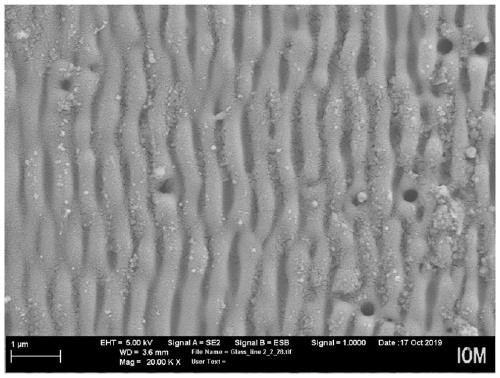

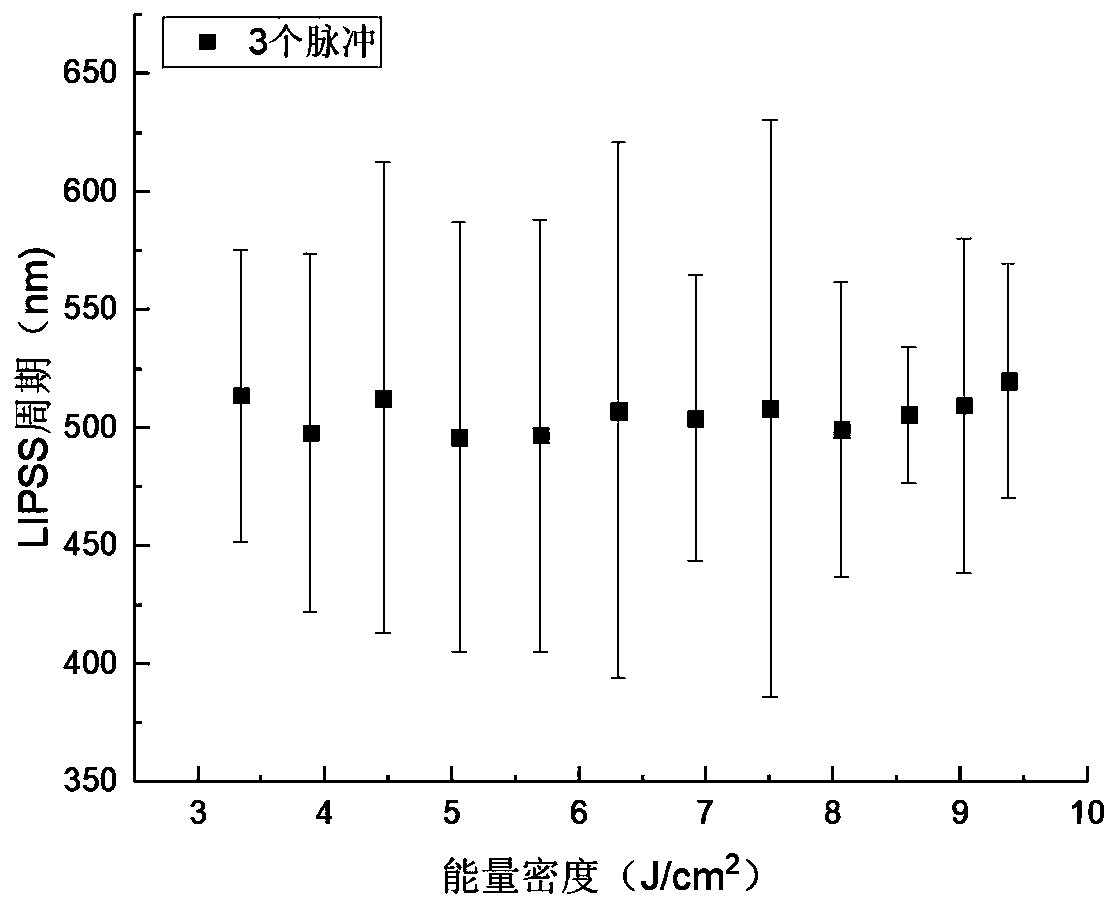

Method for inducing periodic structure on surface of optical glass by picosecond laser

InactiveCN111168233AChange optical propertiesReduce surface reflectivityLaser beam welding apparatusPicosecond laserOptical property

The invention discloses a method for inducing a periodic structure on the surface of optical glass by picosecond laser. The method specifically comprises the following steps: a picosecond laser beam is focused on the surface of the optical glass through a beam expanding and focusing device, after 1-20 pulses act, LIPSS is formed on the surface, and the energy density range of the single laser is 0.4-0.9 times of the ablation threshold. The optical characteristics of the glass can be changed, the surface reflectivity is reduced and the transmittance is improved.

Owner:NANJING UNIV OF SCI & TECH

Femtosecond laser amorphism fine machining method for amorphous alloy

InactiveCN100475433CNo crystallization was foundThe amorphous structure is intactOther manufacturing equipments/toolsLaser beam welding apparatusAmorphismOptoelectronics

The invention relates to a non-crystal fine processing method which uses femtosecond laser to process non-crystal alloy, wherein said method uses femtosecond laser to make hole, etch, and cut the non-crystal alloy, while the impulse energy density of femtosecond laser is 50-100H / cm2 and the impulse width is 45-100fs in holing; the impulse energy density is 3-15J / cm2, the impulse width is 45-100fs, and the scanning speed is 100-200 mum / s in etching line; the impulse energy density is 75-110J / cm2, the impulse width is 45-100fs, and the scanning speed is 100-200 mum / s in cutting. The invention can realize sub-micron processing accuracy, without crystallization in etching area.

Owner:HUAZHONG UNIV OF SCI & TECH

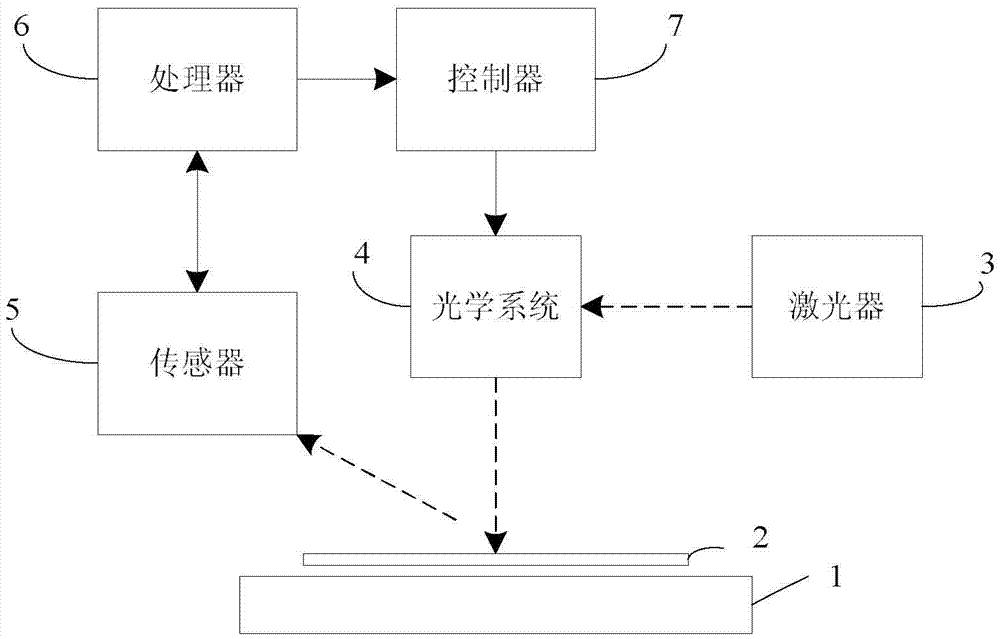

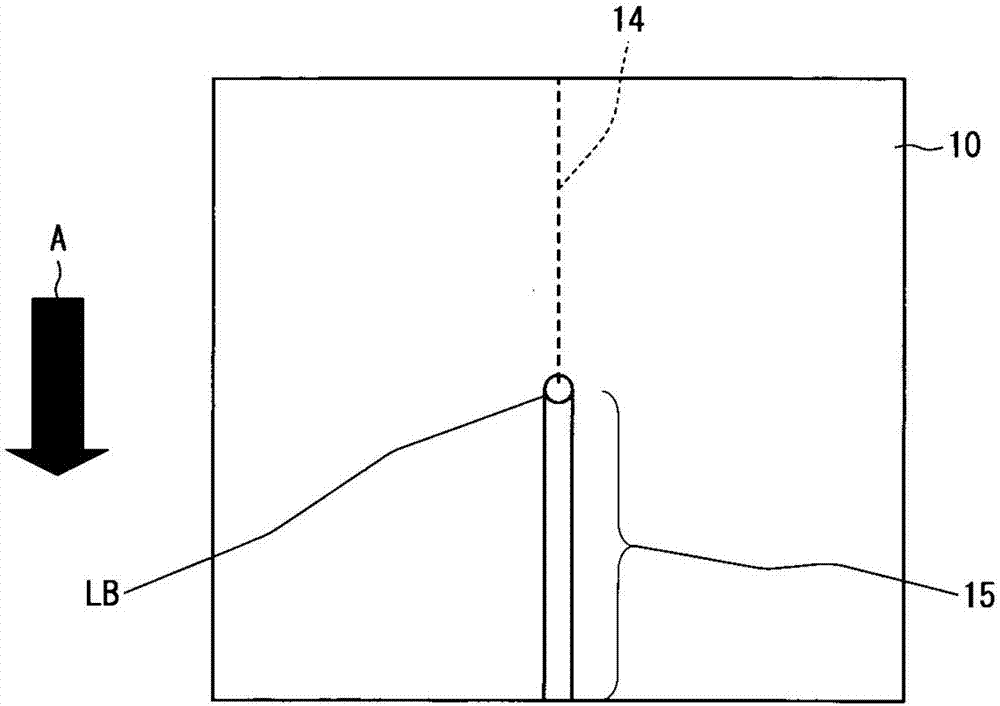

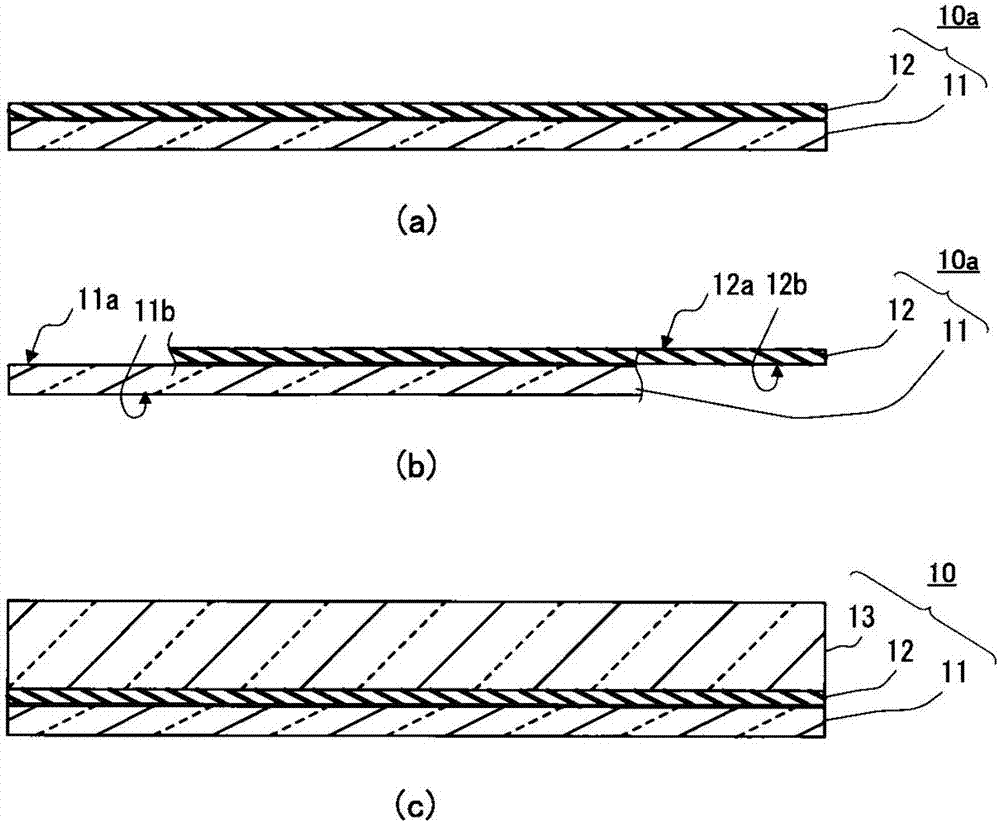

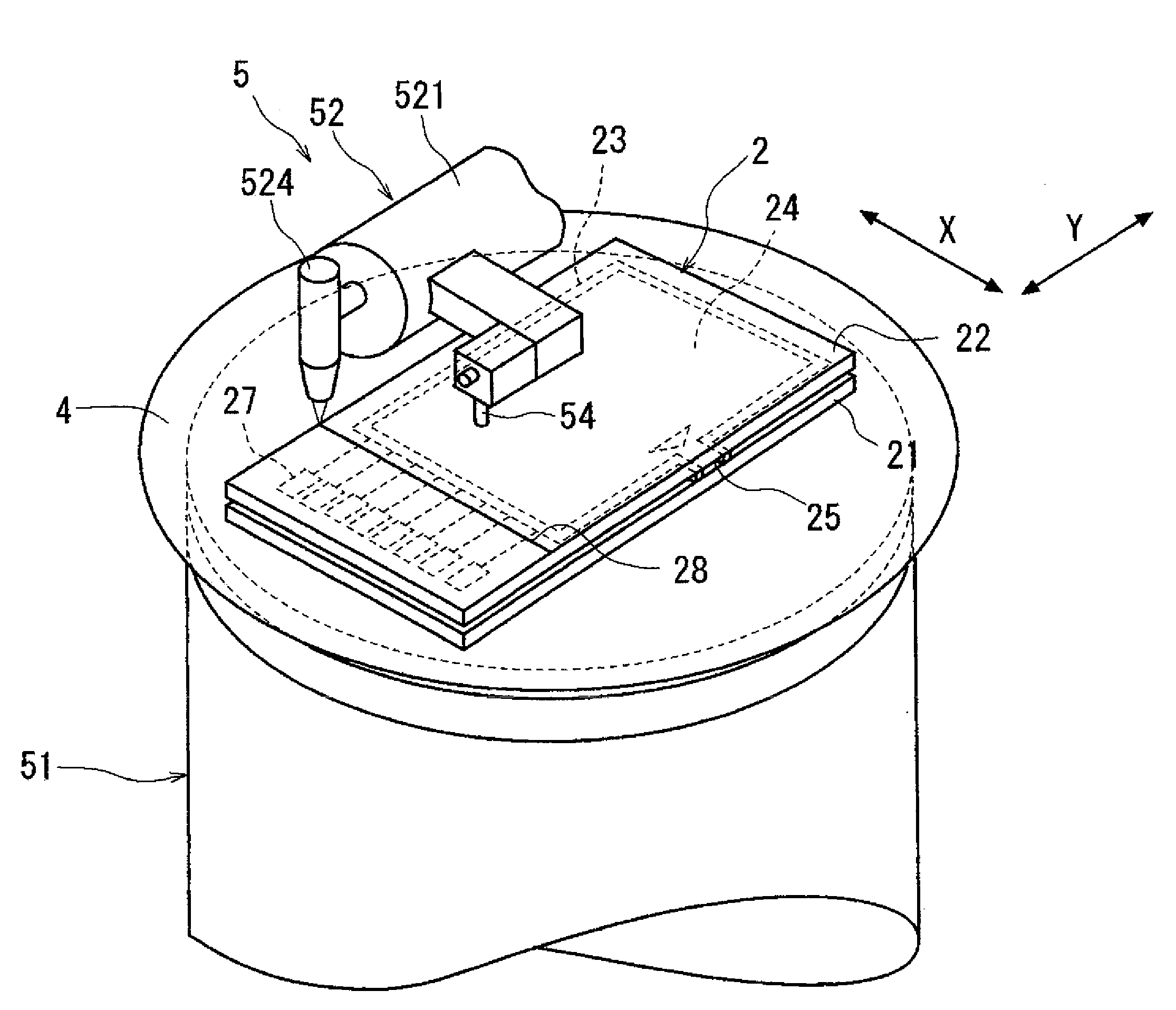

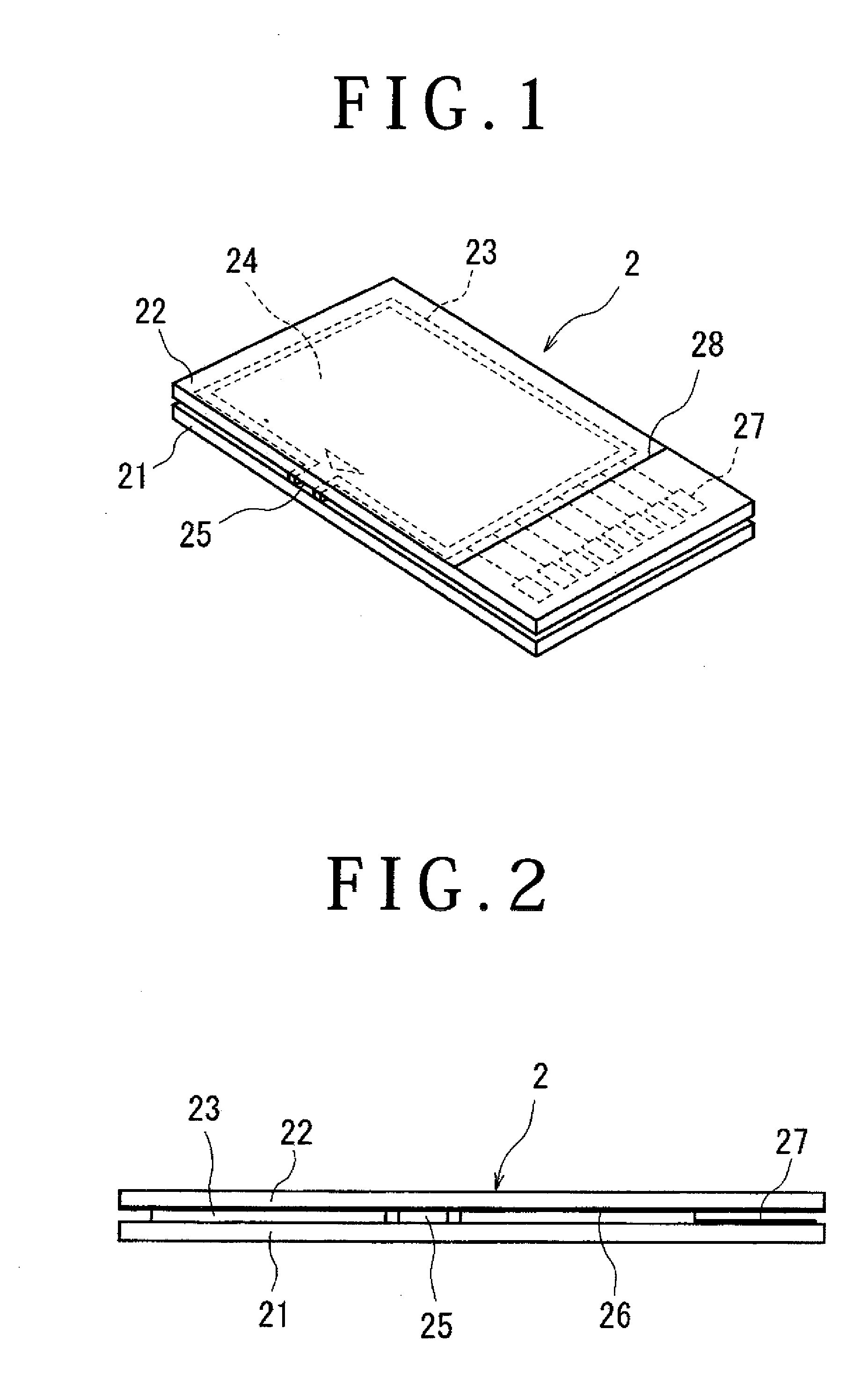

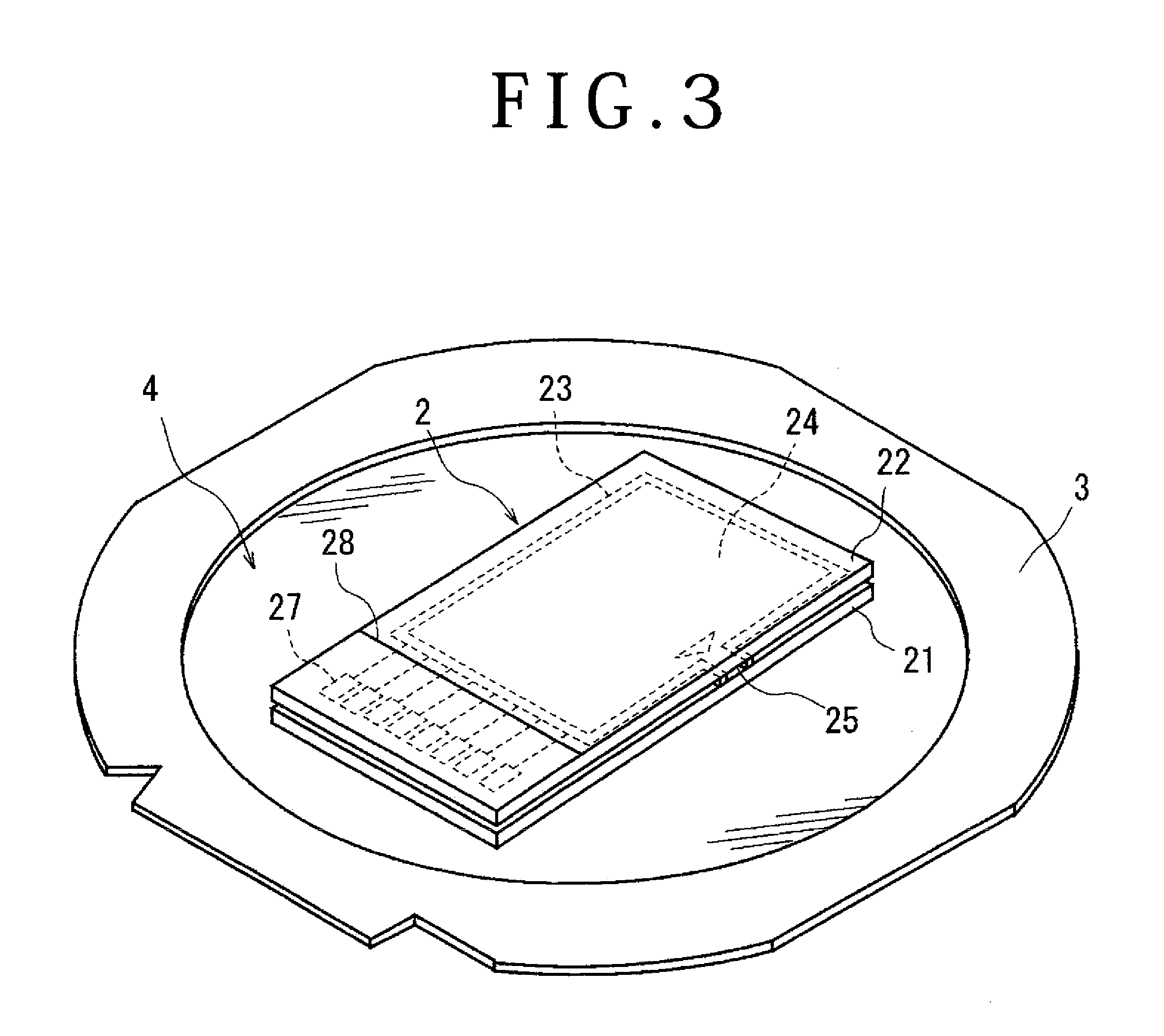

Cutting method for glass laminate

InactiveCN107030393ACut off methodLamination ancillary operationsSynthetic resin layered productsLaser lightOptoelectronics

There is provided a method for cutting a glass laminate which has been reduced in the thickness of the resin layer. Wherein the glass laminate is laminated with a first glass plate and a second glass plate thinner than the first glass plate with a resin layer interposed therebetween, and the cutting method has a method of cutting off the glass (A) and (B): F >= 3 (A), and the pulse energy density F [J / mm2] and the overlap ratio [%] L of the laser light, 0.09L + 11.8 Formula (B). Here, L = (D0-V / f) / D0100, D0 represents the condensed diameter (mm) of the pulse of the laser light, v represents the cutting speed (mm / s), f represents the oscillation frequency of the laser Hz).

Owner:ASAHI GLASS CO LTD

Laser processing method for transparent plate

InactiveUS20090266800A1Glass severing apparatusWelding/soldering/cutting articlesLaser processingLight beam

A laser processing method for a transparent plate having a predetermined breaking line including the step of applying a pulsed laser beam to the transparent plate along the breaking line to thereby form a laser processed groove. The pulsed laser beam has an absorption wavelength to the transparent plate. The repetition frequency of the pulsed laser beam is set to 200 kHz or more and the energy density per pulse of the pulsed laser beam is set to 3.8 J / cm2 or more.

Owner:DISCO CORP

Device and method for removing thin layers on support material

The invention relates to a device and a method for removing thin layers on a support material, especially for removing barrier layers of a thin-layer solar cell. The aim of the invention is to provide an economical means of removing strips of up to a few millimetres in width without damaging the substrate of the thin-layer solar cell underlying the layer to be removed. To this end, a laser treatment device with a laser resonator and an optical system is provided. The optical system projects the treatment beam produced by the layer resonator over an area of 1 mm<2> to 1 cm<2> on the surface to be treated with an essentially homogenous distribution of power. Thin layers can be effectively removed from the substrate at pulse width of less than 100 ns and with a pulse energy density of 0.1 J / cm<2> to 10 J / cm<2>.

Owner:壳牌太阳能股份有限公司

Hollow glass microsphere candidates for reversible hydrogen storage, particularly for vehicular applications

InactiveUS8663429B2Improve system efficiencyHigh realizable packing densityReversible hydrogen uptakeOther chemical processesInitial permeabilityMicrosphere

A source of hydrogen is a glass or glass-ceramic shell and a gas comprising at least 80% by volume of hydrogen. The glass shell has an initial permeability to hydrogen gas of less than about 50% decrease in pressure in 30 days and a final permeability to hydrogen of about 50% decrease in pressure in a few minutes or less, upon exposure of the glass to a continuous or pulsed fluence of at least 0.1 W / cm2 of electromagnetic radiation to modulate the microstructure of the glass and to increase the hydrogen gas permeability of the glass network. A method of providing hydrogen gas in the shell and exposing the shell to electromagnetic radiation of a wavelength and fluence that increases permeability of the shell to hydrogen gas so that encapsulated hydrogen gas permeates through the shell.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION OF BEHALF OF THE UNIV OF NEVADA LAS VEGAS THE

Method for writing double holographic grating at one time by single pulsed laser

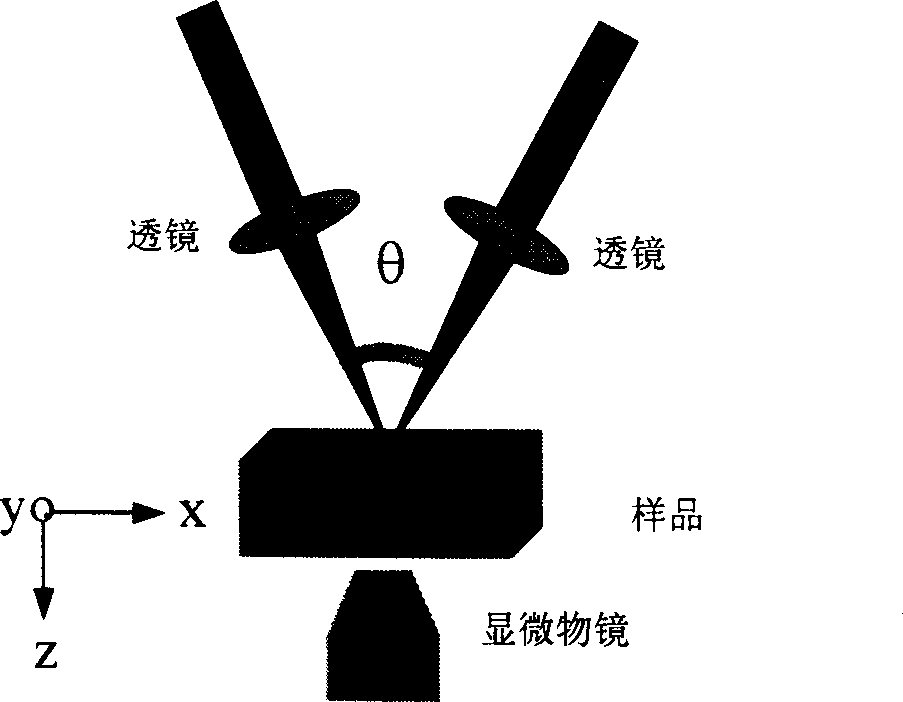

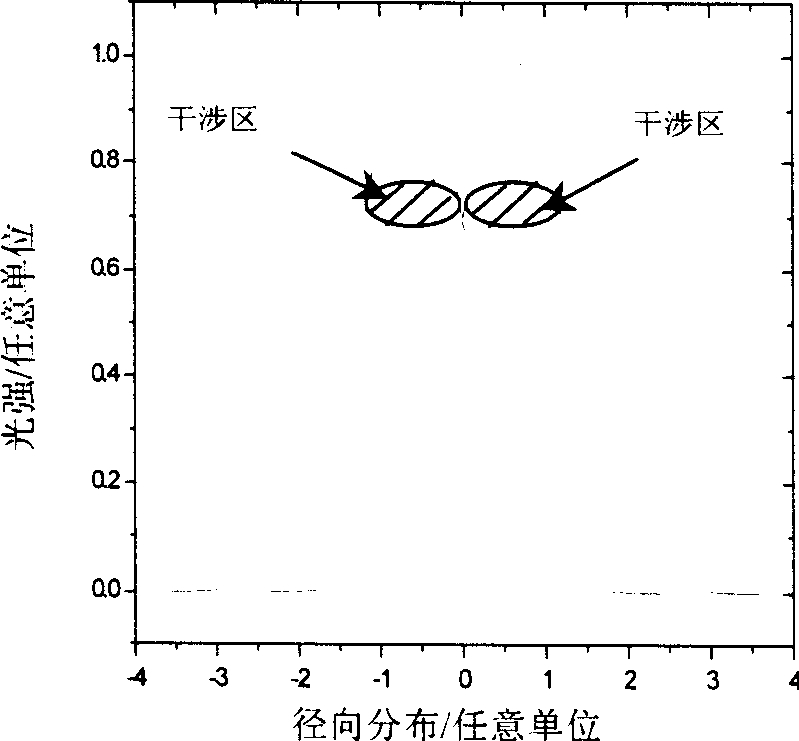

The once double holographic micro grating writing process includes the following steps: adopting supershort pulse laser with pulse width smaller than 1 ps; splitting in a splitter into two beams focused separately by two convexes and crossed at or near the focus to realize temporal and spatial coherent; adopting transparent solid medium; controlling the energy of single pulse output by the laser to make each of the split pulse possess energy density smaller than that energy density threshold to ablate the transparent medium and the energy density reached in constructive interference just greater than the threshold; converging the two coherent supershort laser beams onto the surface of the transparent medium to produce two periodical microstructures and to form double holographic micro grating simultaneously.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

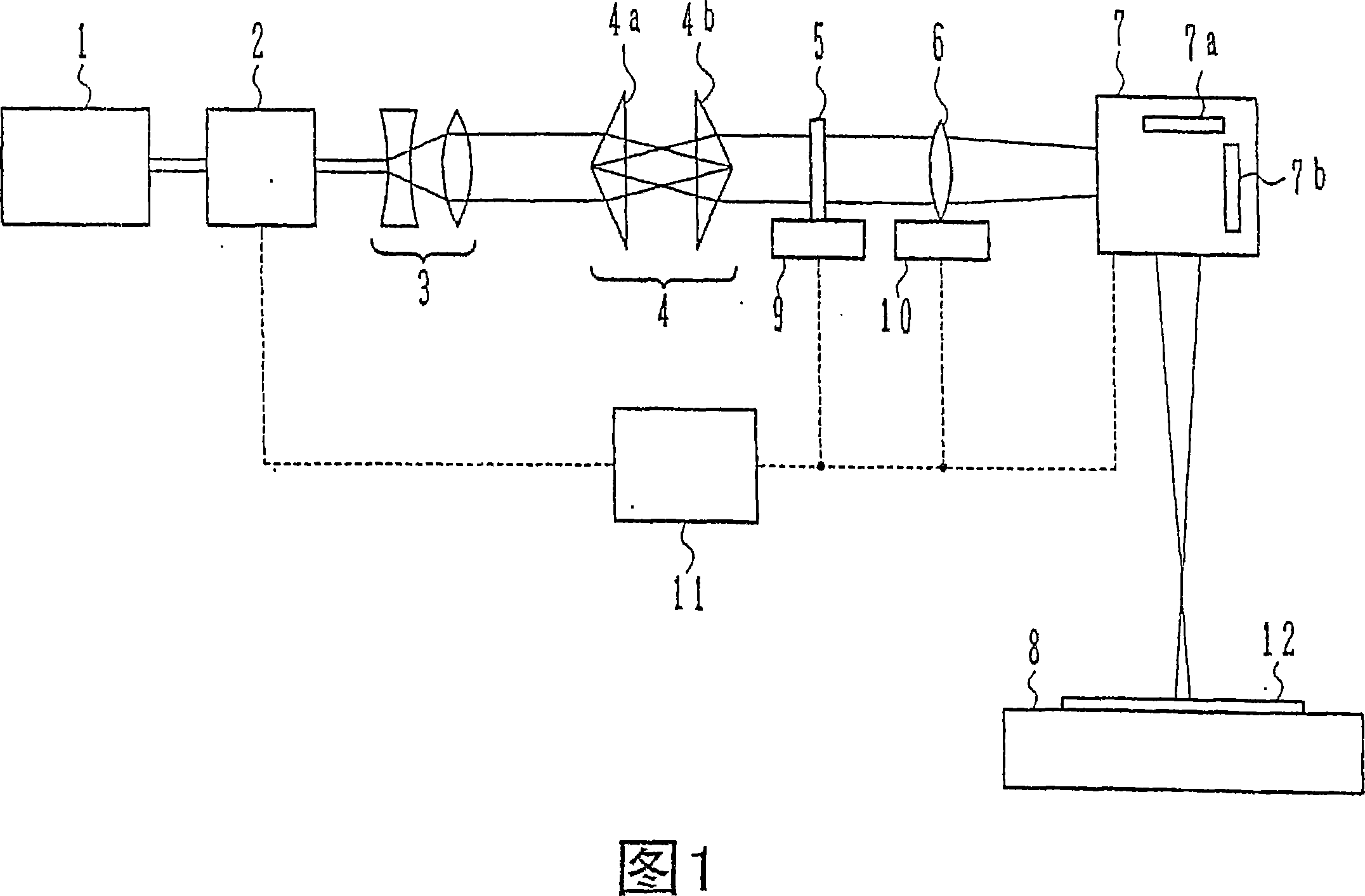

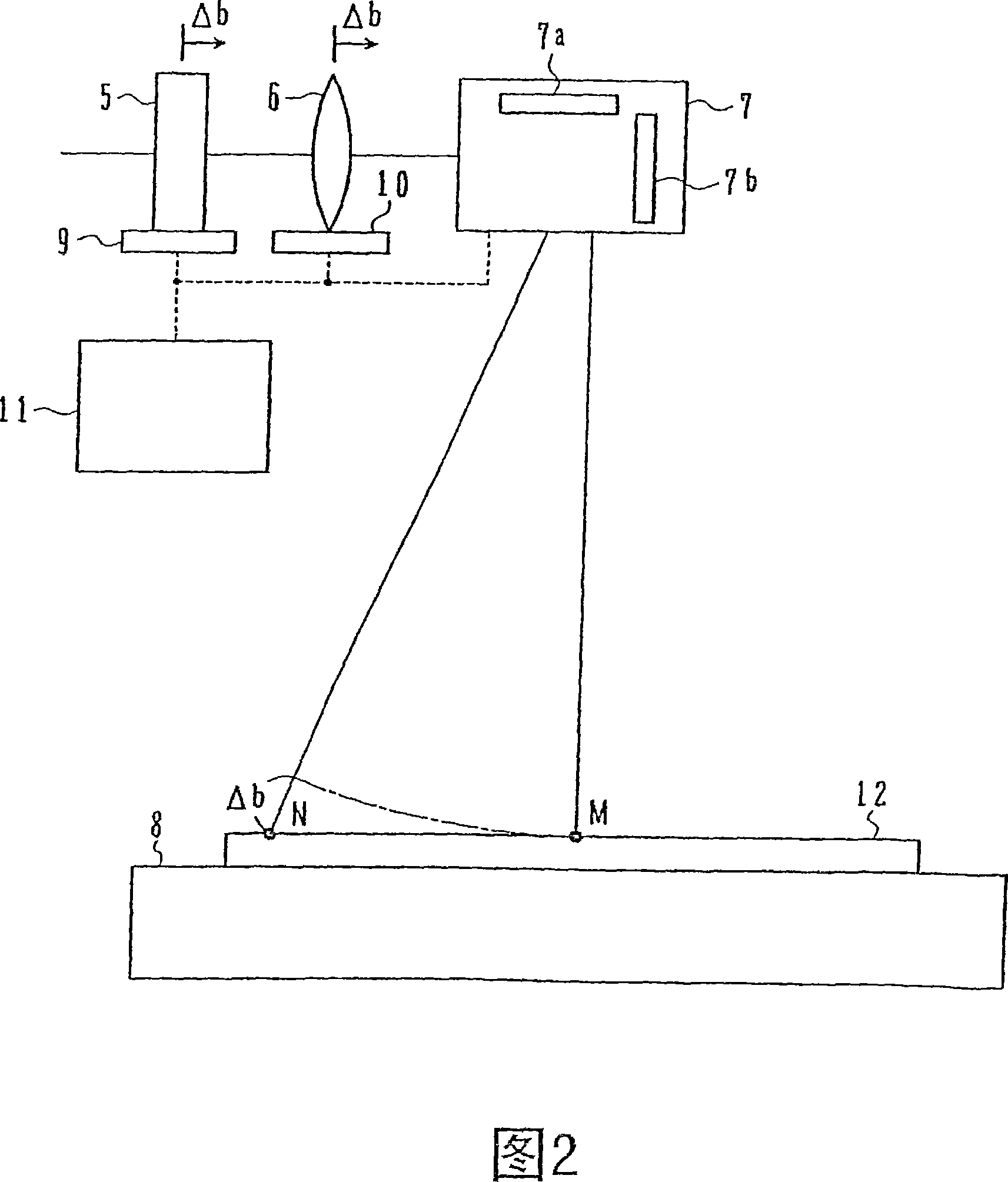

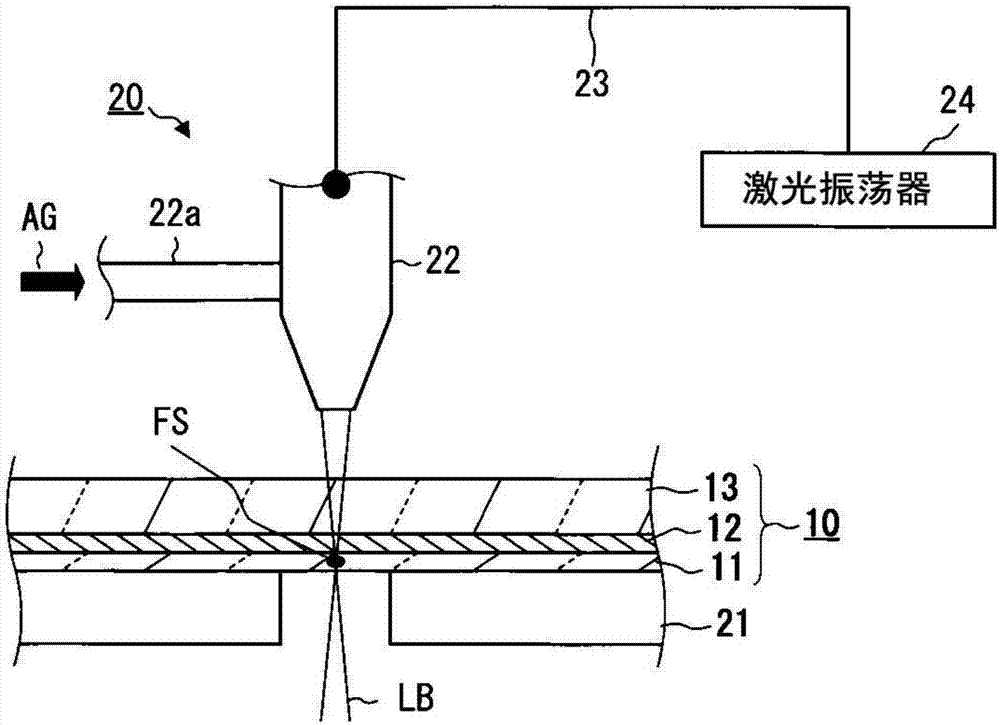

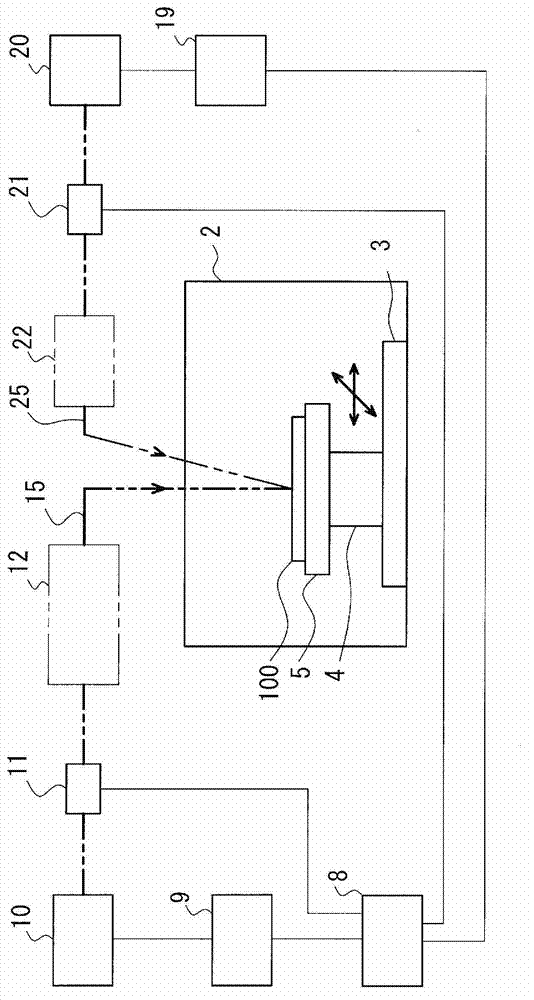

Laser annealing device and laser annealing method

ActiveCN103081065ASmall diameter deviationReduce biasSemiconductor/solid-state device manufacturingLaser beam welding apparatusAbnormal grain growthEffective power

The present invention enables uniform crystallization of a semiconductor film by means of laser annealing. The present invention comprises a pulse laser oscillating device for outputting a pulse laser beam, and an optical transmission means for transmitting the pulse laser beam outputted from the pulse laser oscillating device to irradiate onto the semiconductor film. Since the pulse laser beam, which has an effective power density on the irradiated surface of the semiconductor film calculated by the formula of effective power density (J / (sec.cm3)) = pulse energy density (J / cm2) / pulse width (sec) absorption coefficient of semiconductor film (cm-1), is irradiated onto the semiconductor film so as to be in a range of 3 1012 to 1.5 1012, the semiconductor film can be crystallized without inducing abnormal grain growth due to complete melting, and uniform crystals with little variation are obtained.

Owner:JSW阿克迪纳系统有限公司

Surface protection layer for improving stability of perovskite nanosheet laser and preparation method thereof

InactiveCN111864532AIsolation of water and oxygenImprove stabilityMaterial nanotechnologyLaser detailsWater vaporPhysical chemistry

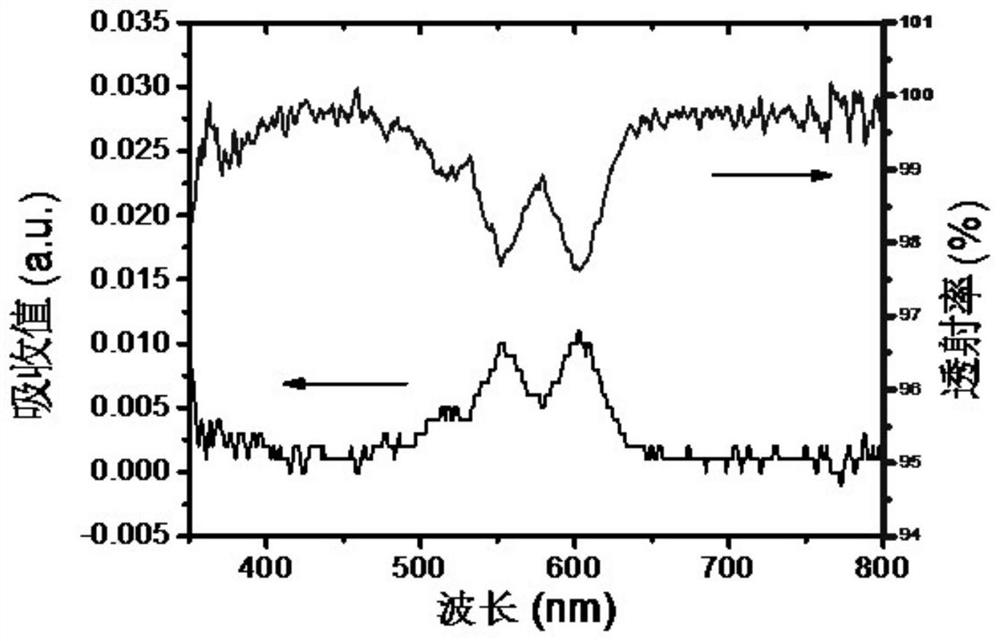

The invention relates to the field of perovskite nanosheet lasers. The invention discloses a surface tetraphenyl dibenzodiindenopyrene (DBP) protective layer for improving the stability of a perovskite nanosheet laser and a preparation method thereof. The good hydrophobic property of the DBP material can effectively prevent water vapor from damaging a perovskite layer, so that the air stability ofthe device is improved. Meanwhile, the electron temperature and the lattice temperature of the active medium of the perovskite layer in the perovskite laser are increased under the condition of highlaser pulse energy density, and the high temperature resistance of the DBP film is beneficial to reducing the thermal decomposition of the perovskite layer, so that the thermal stability of the perovskite laser is improved. The invention relates to the surface protection layer for improving the stability of the perovskite nanosheet laser and the preparation method thereof.

Owner:TAIYUAN UNIV OF TECH

Laser annealing method and laser annealing device

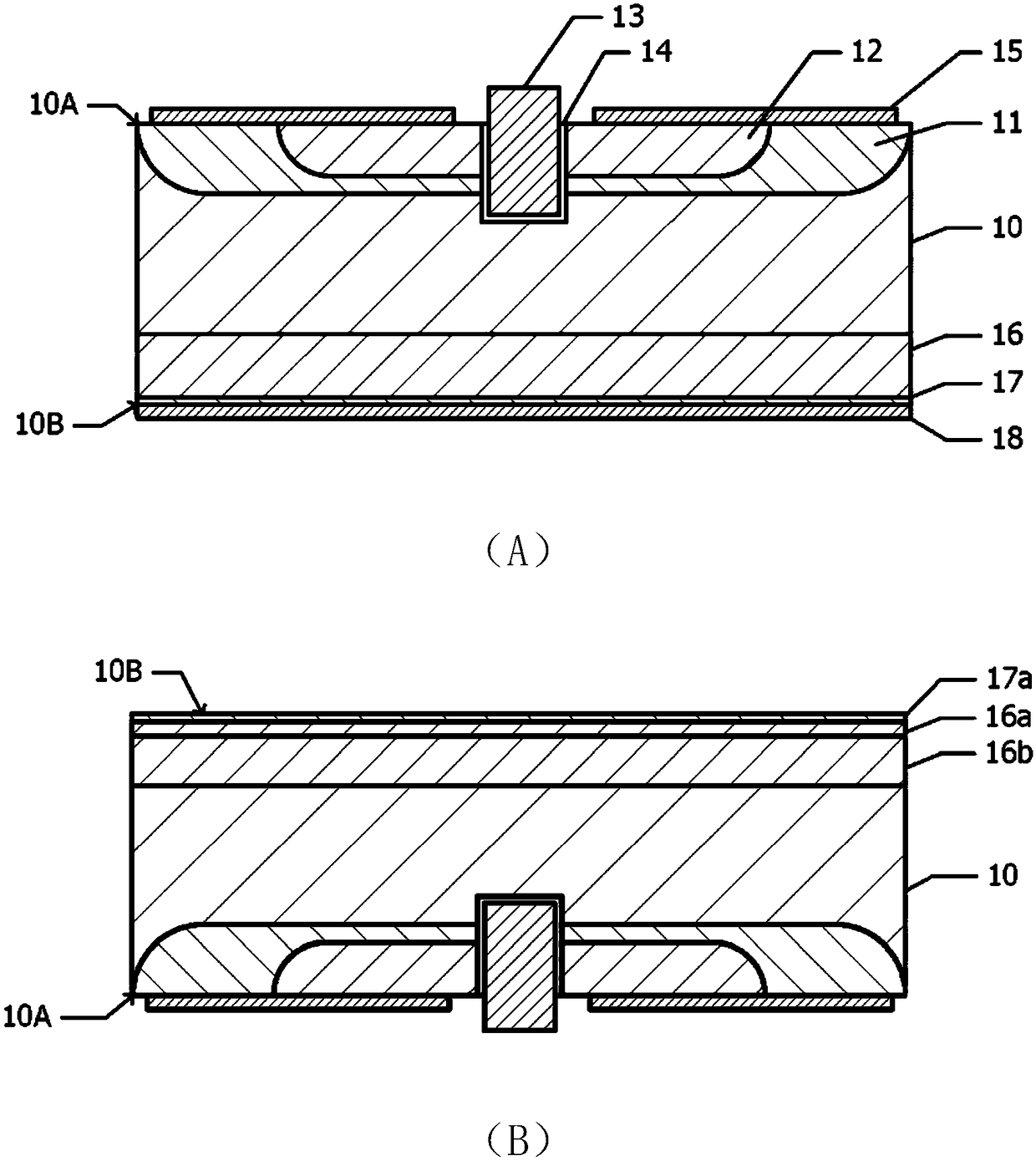

PendingCN109075042AImprove featuresReduce outputSemiconductor/solid-state device manufacturingSemiconductor devicesWaferingPulsed laser beam

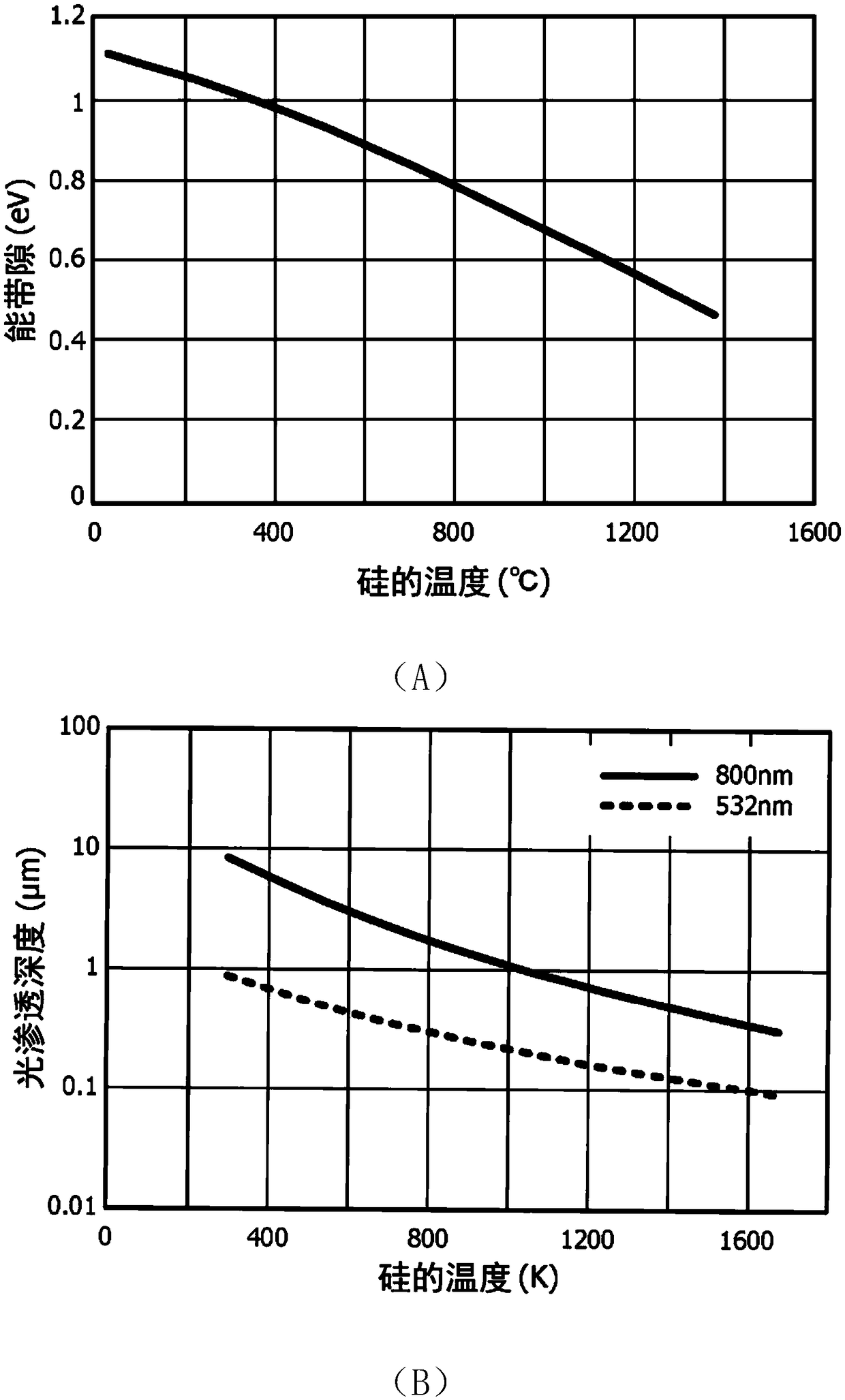

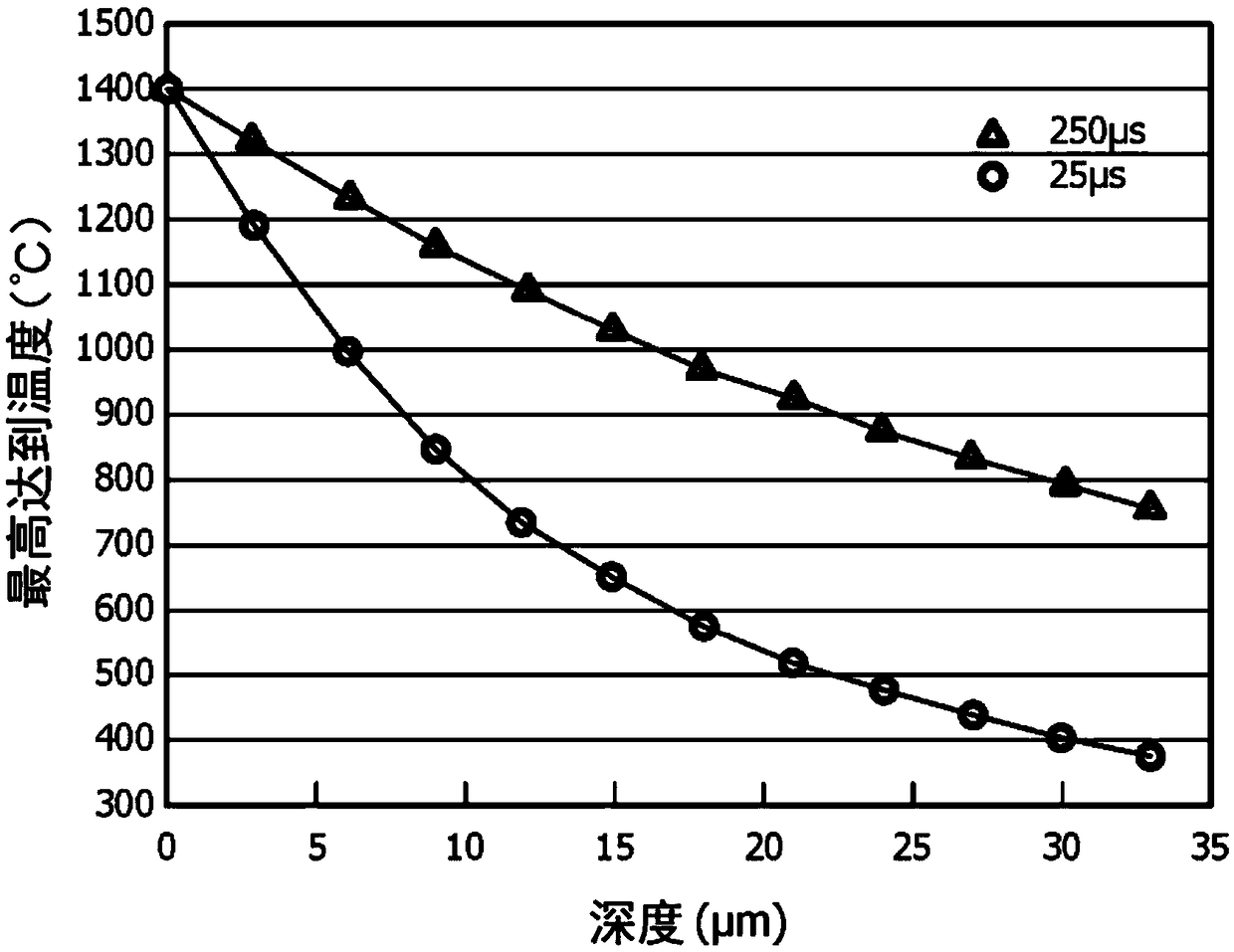

In the present invention, prepared is a silicon wafer having implanted in a surface layer part of one surface thereof an element that forms composite defects which function as donors when activated. Apulsed laser beam having a wavelength in the range of 690 to 950nm inclusive is caused to enter a laser irradiation surface of the silicon wafer, which is the surface where the element has been implanted, in order to activate the element. During the activation of the element, the pulse width of the pulsed laser beam and the pulse energy density are set such that the pulsed laser beam enters the silicon wafer under the conditions that the element in at least some regions from the surface to a depth of 40[mu]m is activated without melting the laser irradiation surface.

Owner:SUMITOMO HEAVY IND LTD

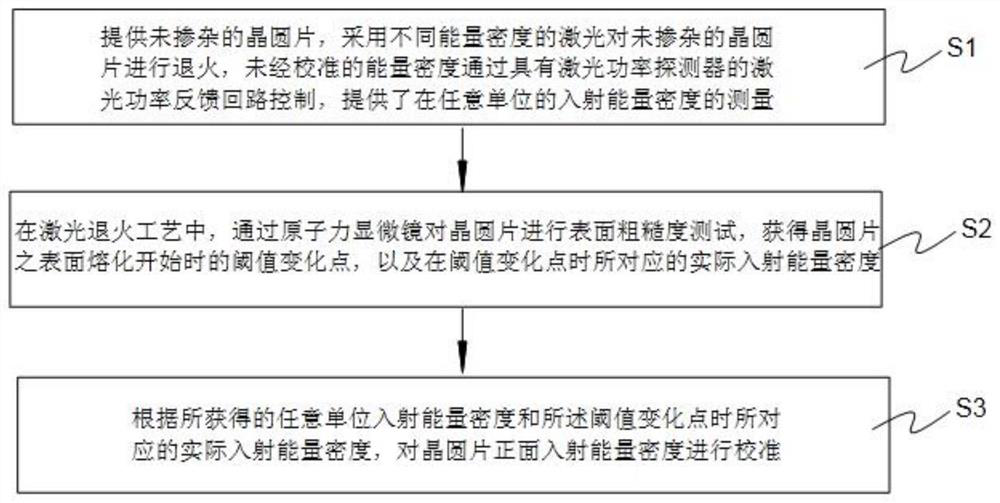

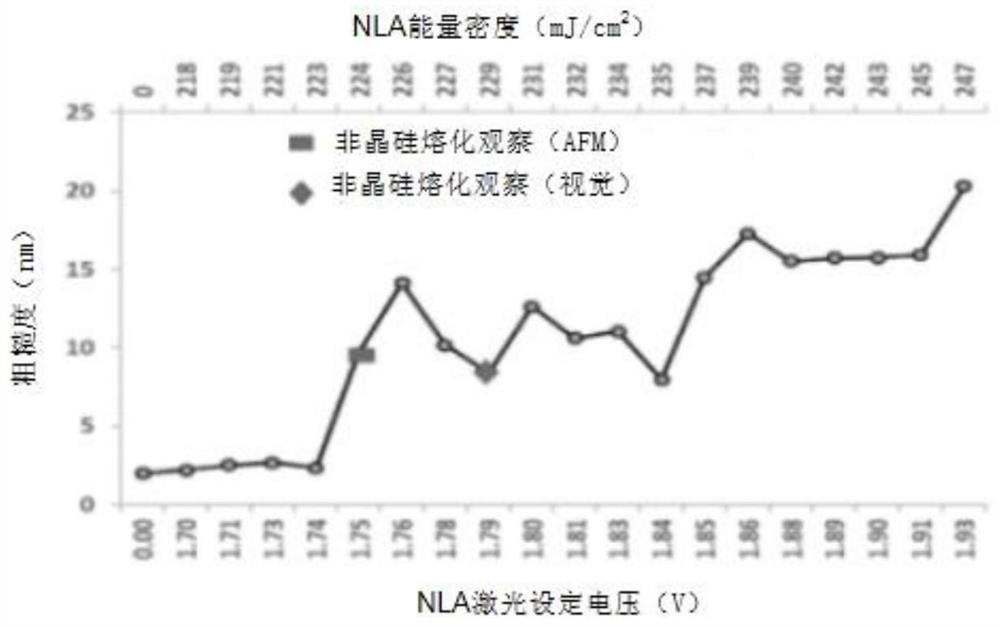

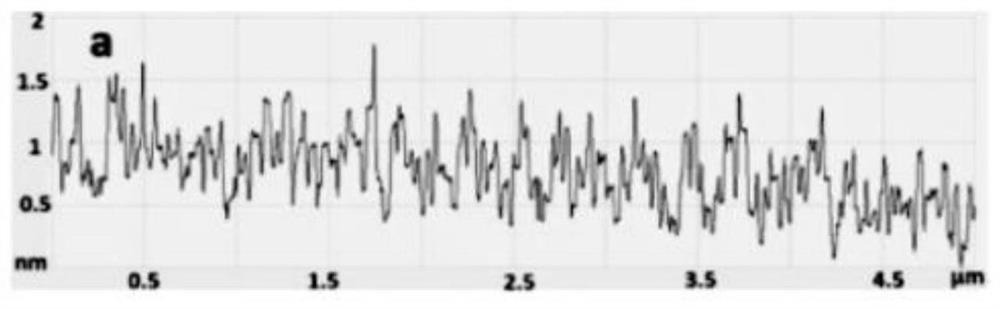

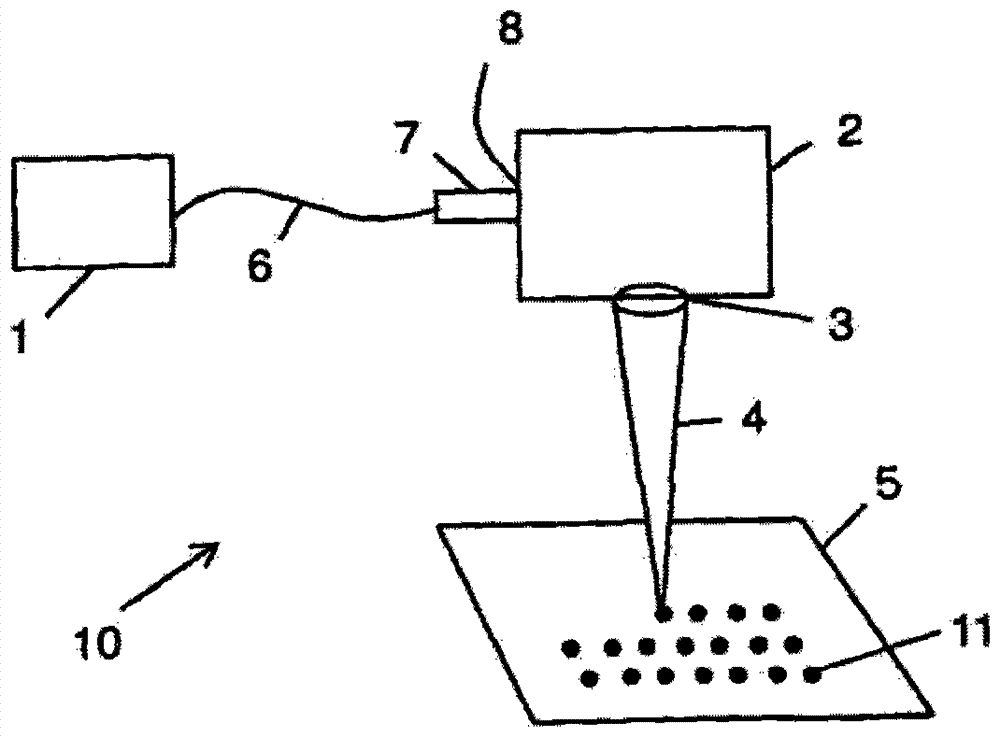

Method for calibrating incident energy density of front surface of wafer

PendingCN114141617ASemiconductor/solid-state device manufacturingLaser beam welding apparatusWaferIncident energy

The invention relates to a method for calibrating the incident energy density of the front surface of a wafer, which comprises the following steps of: providing an undoped wafer, annealing by adopting laser with different energy densities, controlling the uncalibrated energy density by a feedback loop, and providing the measurement of the incident energy density in any unit; in the annealing process, surface roughness testing is conducted on a wafer through an AFM, and a threshold value change point at the beginning of surface melting and the corresponding actual incident energy density are obtained; and according to the incident energy density of any unit and the actual incident energy density corresponding to the threshold value change point, incident energy density calibration is carried out. According to the method, the incident laser pulse energy density is calibrated by using the sudden threshold change of the surface roughness measured by the AFM at the beginning of wafer surface melting; performing incident ED period monitoring on sub-melt boron doping activation of the silicon substrate at the temperature of 1300 DEG C; tool and process matching is performed using epitaxial regrowth of an amorphous doped silicon phosphorus layer at 1200 DEG C or below, and the matching is in the range of 1% of the energy density.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method of laser marking metal surface with desired color

ActiveCN103831534BDuplicating/marking methodsWelding/soldering/cutting articlesOptoelectronicsLaser beams

A method for laser marking a metal surface (5) with a desired colour, which method comprises forming at least one first pattern (41) on the metal surface (5) with a first laser beam (42) having a first pulse fluence (43), forming at least one second pattern (51) on the metal surface with a second laser beam (52) having a second pulse fluence (53), characterized by causing the second pattern (51) to overlay the first pattern (41), arranging the first pulse fluence (43) to be at least five times greater than the second pulse fluence (53), the colour being given by the first and second pulse fluences (43, 53) and spot spacings (48) in the first and second patterns (41, 51), and selecting the first and second pulse fluences (43, 53) and the spot spacings (48) to form the desired colour.

Owner:SPI LASERS UK

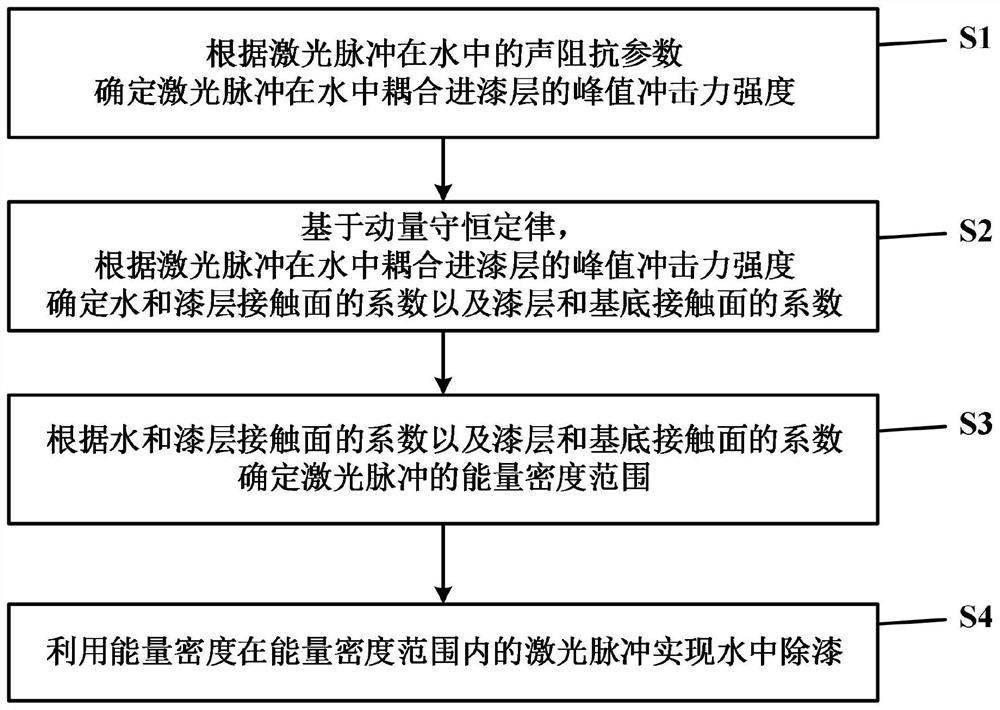

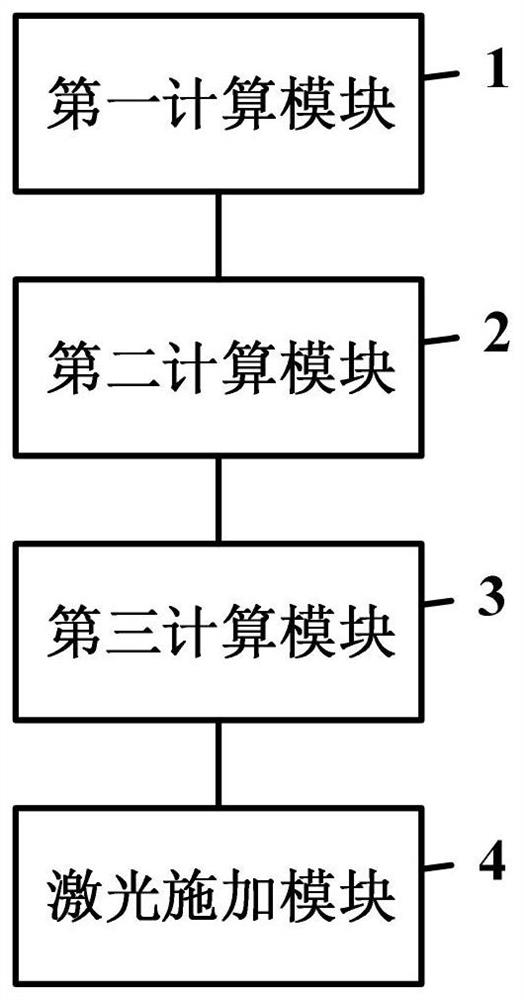

Method and device for removing paint in water

ActiveCN113070287BEfficient removalWon't breakCleaning processes and apparatusEngineeringMechanical engineering

The invention relates to the technical field of laser cleaning, in particular to a method and device for removing paint in water. The method includes: determining the peak impact force intensity of the laser pulse coupled into the paint layer in water according to the acoustic impedance parameters of the laser pulse in water; The coefficient of the contact surface of the layer and the coefficient of the contact surface of the paint layer and the substrate; the energy density range of the laser pulse is determined according to the coefficient of the contact surface of water and the paint layer and the coefficient of the contact surface of the paint layer and the substrate. In practical applications, as long as the selected laser energy density is within the determined laser pulse energy density range, the laser pulse can be used to remove the paint layer in water with high efficiency and high quality.

Owner:SICHUAN UNIV

A method of using multi-band narrow-band high-power microwaves to test the damage effect of electro-acoustic alarm controllers

ActiveCN106959396BOverall clarityStrong targetingMeasuring interference from external sourcesMulti bandMicrowave

The invention discloses a multiple wave band narrowband high power microwave-based damage effect test method for an electroacoustic alarm controller. The electroacoustic alarm controller is placed in a test zone, and the method comprises the following steps: in step a1, L wave band high power microwave radiation is set in a system, and the electroacoustic alarm controller faces right to radiation wave waves; in step a2, the electroacoustic alarm controller faces sideways to the radiation wave waves; in step a3, the electroacoustic alarm controller faces in a direction opposite to the radiation waves; in step a4, a polarization mode is changed to a vertical polarization mode; in step a5, a wire cable is hidden in wave absorbing material; in step a6, minimum pulse energy density in steps from step a1 to step a5 is chosen as an interference threshold value for a sample; in step a7, the sample is changed, the steps from step a1 to step a6 are repeated; in step a8, a threshold value range of damage caused on the electroacoustic alarm controller by a wave band high power microwave; in step a9, the microwave radiation system is orderly adjusted to be an S wave band microwave radiation system, a C wave band microwave radiation system and an X wave band microwave radiation system; the test steps from step a1 to step a8 are repeated. The damage effect test method is advantaged by well-organized structure, strong pertinency, easy-to-implement property and the like.

Owner:UNIT 61489 OF PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com