Method and device for removing paint in water

A paint layer and contact surface technology, applied in the field of laser cleaning, can solve the problems of low efficiency, time-consuming and labor-intensive, affecting the efficiency and effect of paint layer removal, achieve high-quality removal, and solve the effect of low-quality removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

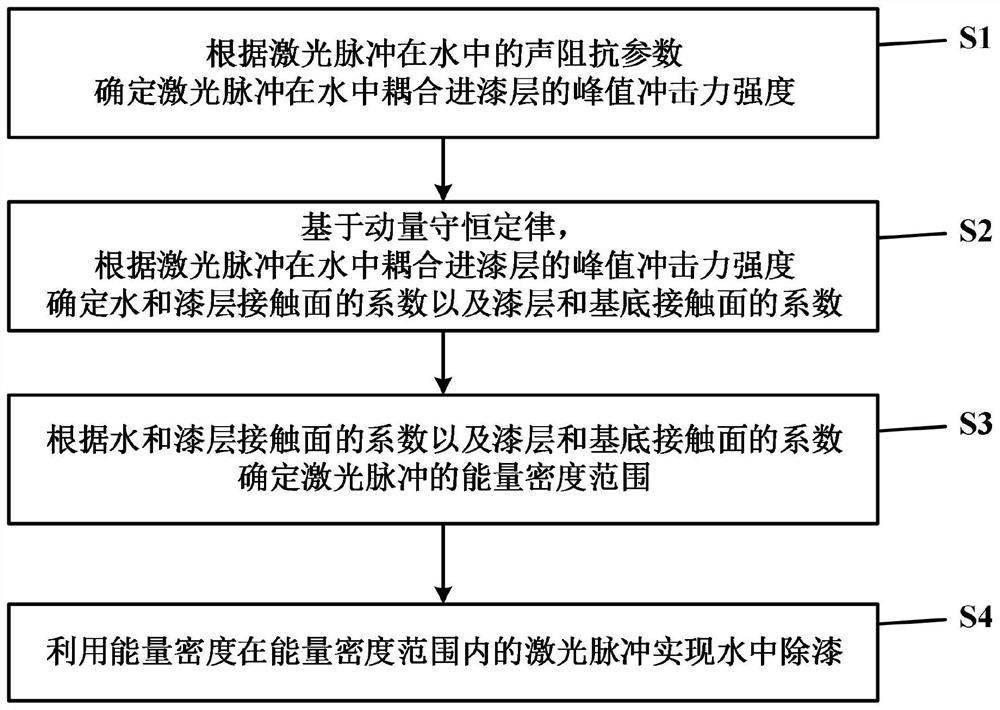

[0051] Such as figure 1 As shown, the present invention provides a method for removing paint in water in Embodiment 1, and S1-S4 in the figure corresponds to each step in the method. Methods include:

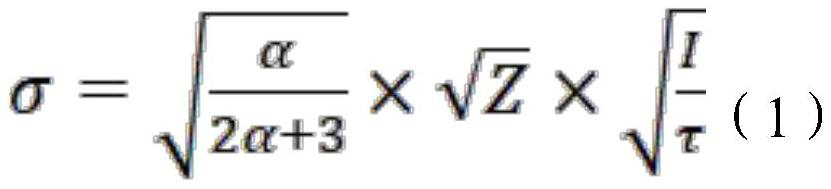

[0052]S1. Determine the peak impact strength of the laser pulse coupled into the paint layer in water according to the acoustic impedance parameters of the laser pulse in water;

[0053] S2. Based on the law of conservation of momentum, determine the coefficient of the contact surface between the water and the paint layer and the coefficient of the contact surface between the paint layer and the substrate according to the peak impact force intensity of the laser pulse coupled into the paint layer in water;

[0054] S3. Determine the energy density range of the laser pulse according to the coefficient of the contact surface of the water and the paint layer and the coefficient of the contact surface of the paint layer and the substrate;

[0055] S4. Using laser pulses with an en...

Embodiment 2

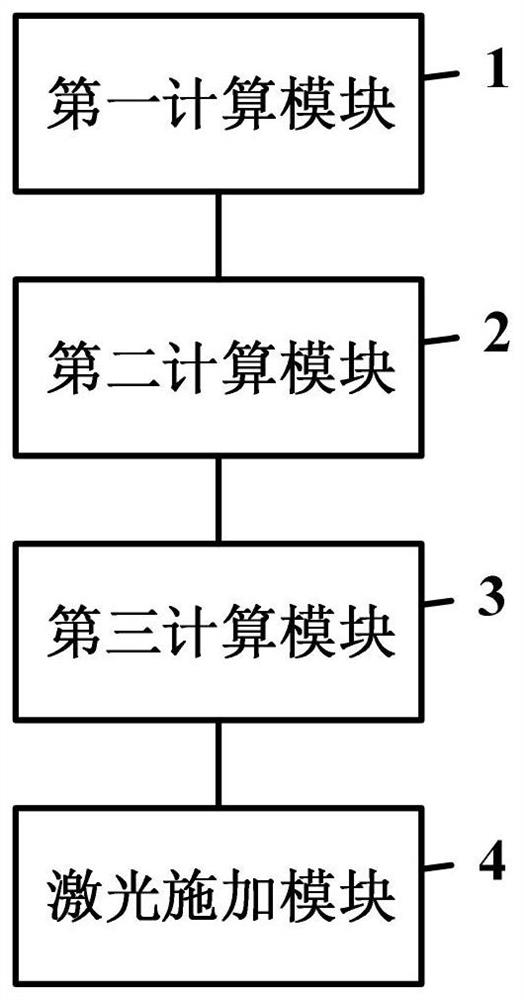

[0125] Such as figure 2 As shown, the present invention provides a kind of paint removal device in water in embodiment 2, realizes based on the paint removal method in water as described in embodiment 1, comprises:

[0126] A first calculation module 1 , a second calculation module 2 , a third calculation module 3 and a laser application module 4 .

[0127] in,

[0128] The first calculation module 1 is used to determine the peak impact force intensity of the laser pulse coupled into the paint layer in water according to the acoustic impedance parameters of the laser pulse in water;

[0129] The second calculation module 2 is used to determine the coefficient of the contact surface between the water and the paint layer and the coefficient of the contact surface between the paint layer and the substrate according to the peak impact force intensity of the laser pulse coupled into the paint layer in water based on the law of conservation of momentum;

[0130] The third calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com