Method for laser marking metal surface with desired colour

A metal surface, laser marking technology, applied in the direction of copying/marking method, laser welding equipment, metal processing equipment, etc., can solve the problems of inconvenient anodization of metal copper, inability to carry out, unable to produce color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

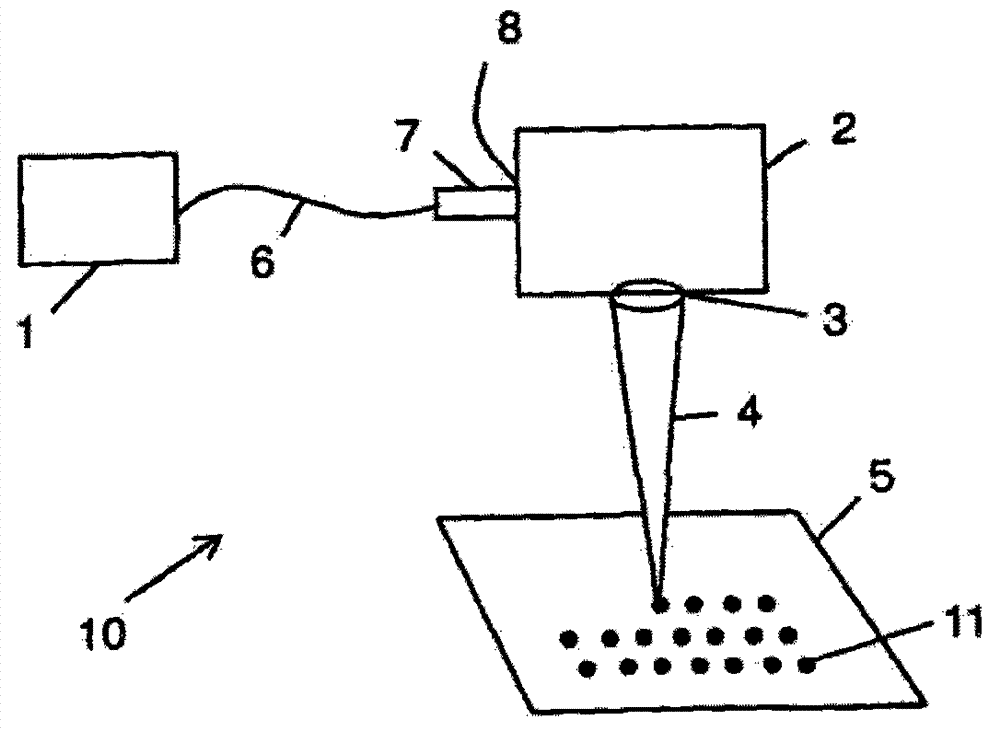

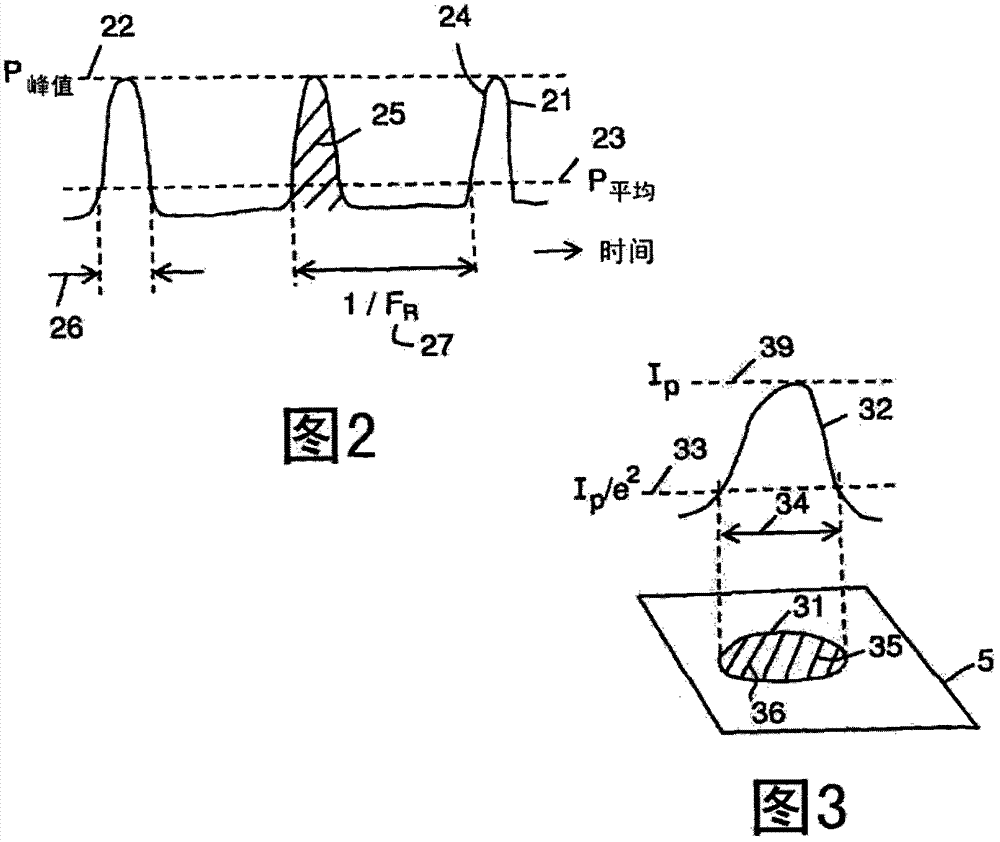

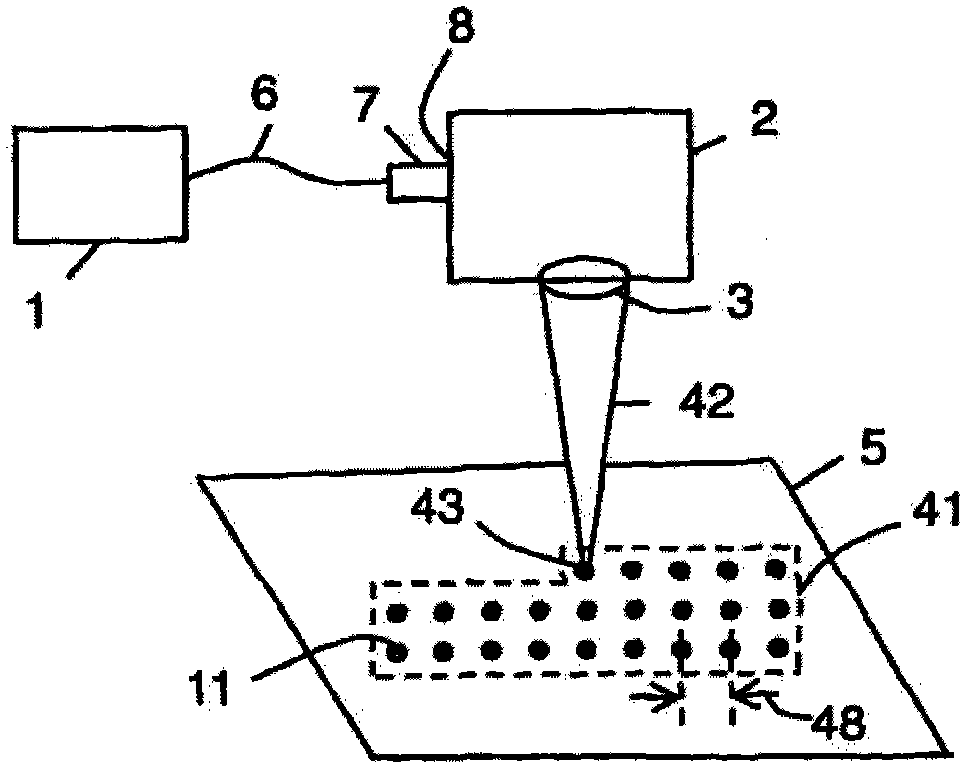

[0061] in the attached Figure 4 , 5 The laser 1 described in is an air-cooled pulsed 20w laser of model G4HS-L produced by SPI Lasers UK Ltd of Southampton, UK. The scanning device 2 is a galvanometer scanning head (also referred to as a scanner) of the model SuperScan II produced by Raylase GmbH in Wessling, Germany. The objective lens 3 is an objective lens with a focal length f-theta of 163 mm. The first laser beam 42 and the second laser beam 52 are transmitted from the laser 1 to the scanning device 2 via a 75mm beam expander collimator (BEC) 7, which can make the laser beams pass through the scanning head entrance 8. With 8mm (1 / e 2 ) of the nominal diameter. This results in a laser beam waist diameter 34 of 50+ / −5.0 μm at the focal plane of the scanner objective 3 . During normal operation of the workstation, the target metal surface 5 is placed at or near the focal plane.

[0062] The laser 1 is capable of generating pulses in the nanosecond range (between appro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak power | aaaaa | aaaaa |

| Peak power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com