Method for calibrating incident energy density of front surface of wafer

A technology of incident energy and energy density, used in laser welding equipment, electrical components, circuits, etc., can solve the problems of low activation efficiency of sub-melt nanoscale, limited selection of ultra-high-speed pyrometers, and unreliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

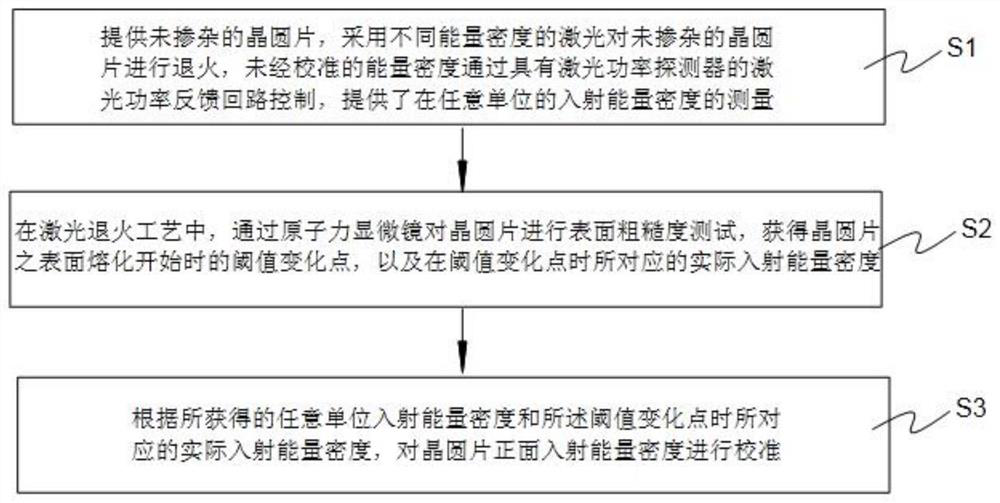

[0036] see figure 1 , figure 1 Shown is a flow chart of the method for calibrating the front incident energy density of the wafer according to the present invention. The method for calibrating the front incident energy density of the wafer includes:

[0037] Executing step S1: providing an undoped wafer c-Si (100), using lasers with different energy densities to perform laser annealing on the undoped wafer, the uncalibrated energy density (ED) is obtained by having Laser power feedback loop control of the laser power detector, providing measurement of incident energy density in arbitrary units;

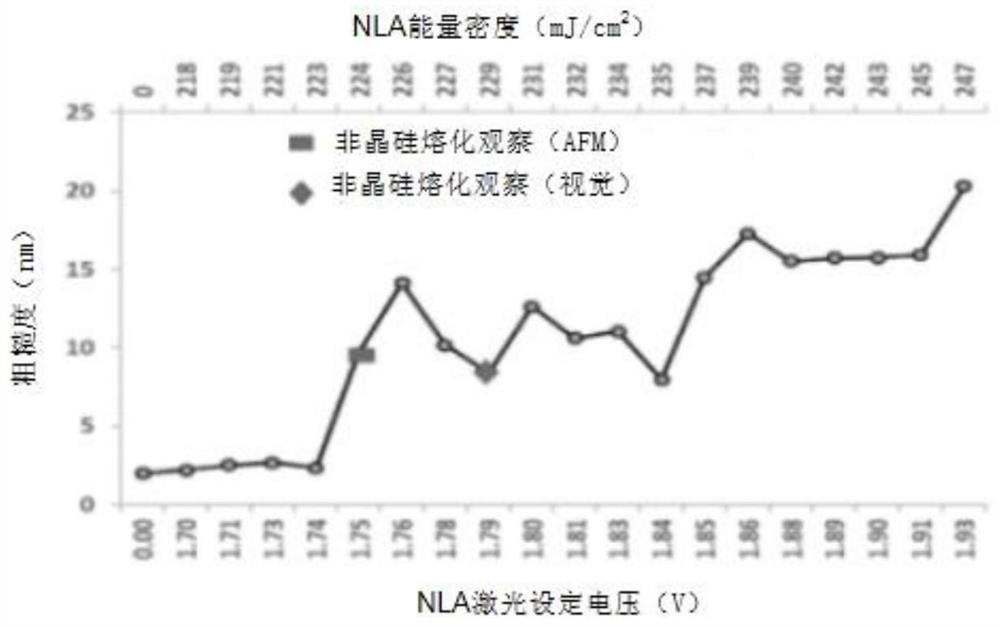

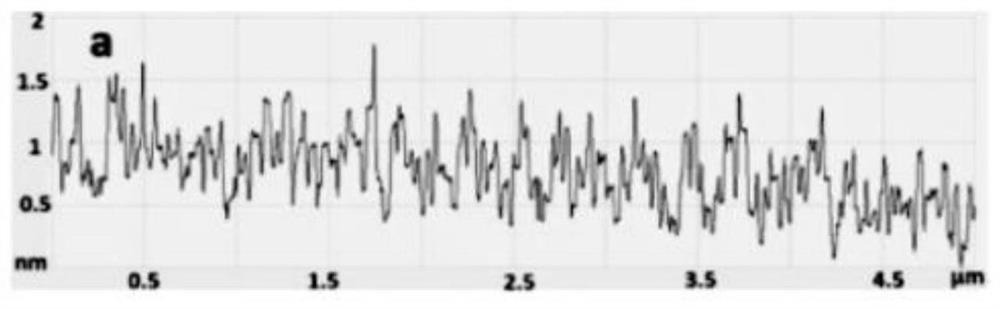

[0038] Execute step S2: in the laser annealing process, conduct a surface roughness test on the wafer through an atomic force microscope (AF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com