Laser annealing method and laser annealing device

A technology of laser annealing and laser beam, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the crystal state and disturbance, and achieve the effect of improving the characteristics of the components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

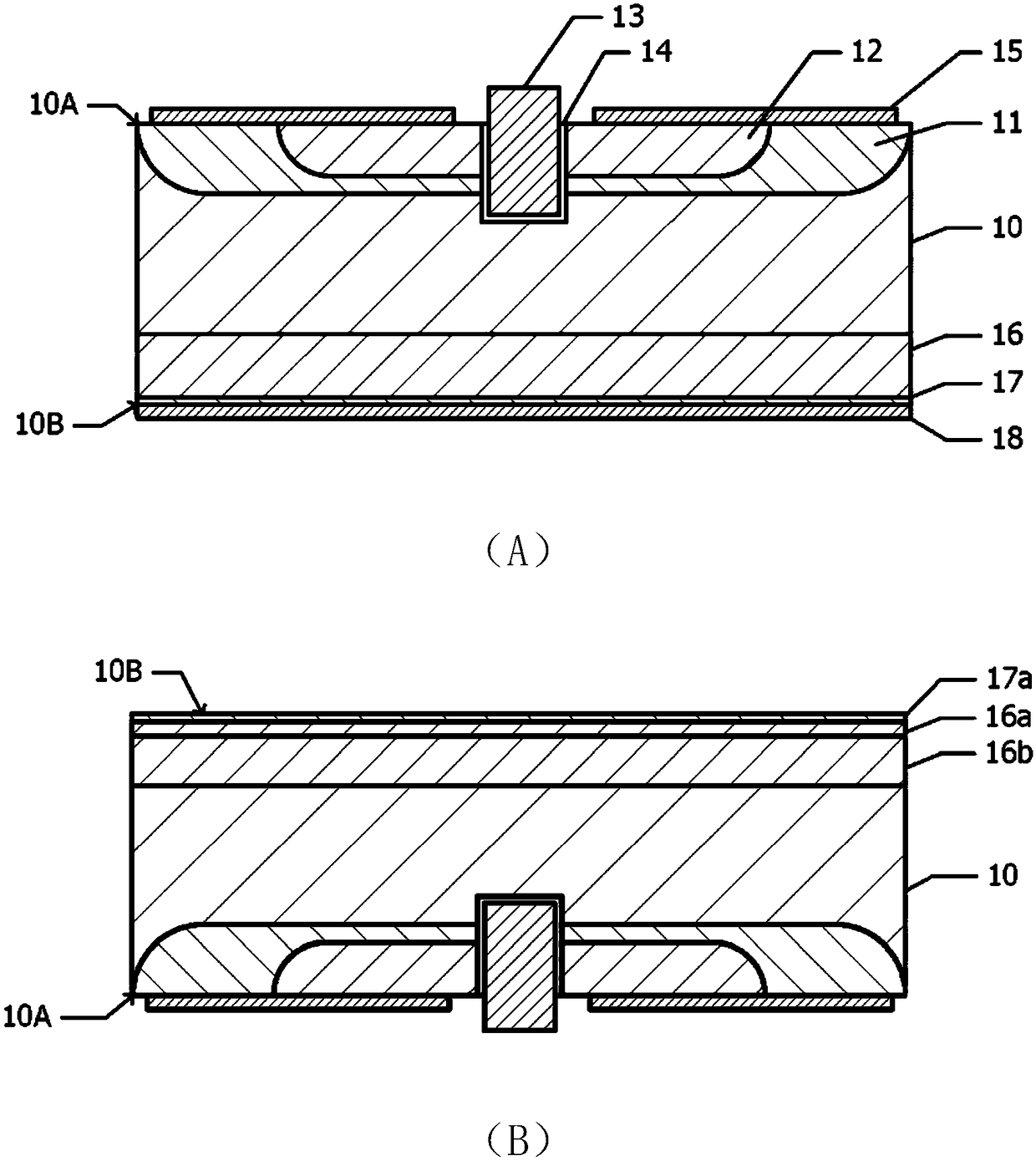

[0065] Below, refer to figure 1 (A) and (B) briefly describe the structure of a semiconductor element, such as an insulated gate bipolar transistor (IGBT), manufactured by the laser annealing method based on the embodiment.

[0066] figure 1 Middle (A) is a cross-sectional view of an IGBT manufactured by the laser annealing method based on the example. Element structures such as emitters and gates are formed on one surface (hereinafter referred to as "non-irradiated surface") 10A of n-type silicon wafer 10, and collector structures are formed on the other surface (hereinafter referred to as "laser irradiated surface") 10B. electrode.

[0067] For example, if figure 1 As shown in (A), a p-type base region 11, an n-type emitter region 12, a gate electrode 13, a gate insulating film 14, and an emitter electrode are arranged on the surface portion of the non-irradiated surface 10A of the silicon wafer 10. electrode 15. Current switching control can be performed using the gate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com