Cutting method for glass laminate

A technology of glass layers and laminates, applied in glass cutting devices, glass/slag layered products, glass manufacturing equipment, etc., can solve the problems of easy bending and low rigidity, and achieve the effect of reducing cutting residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

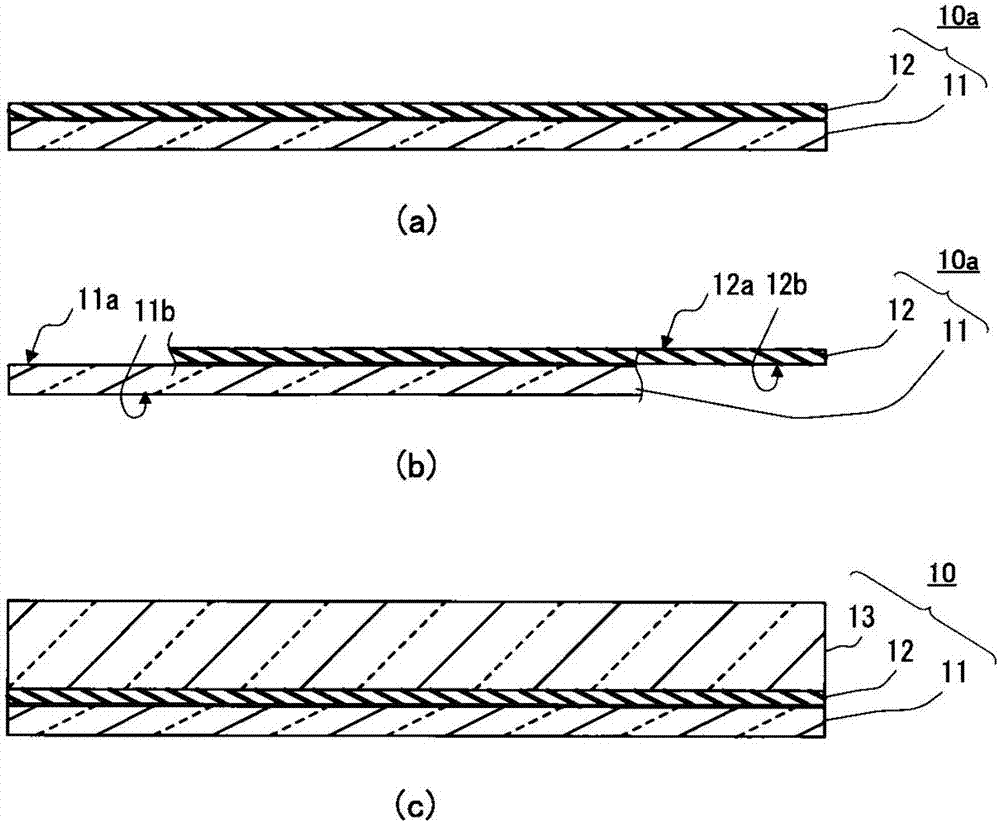

[0210] Here, examples and comparative examples obtained by changing cutting conditions will be described.

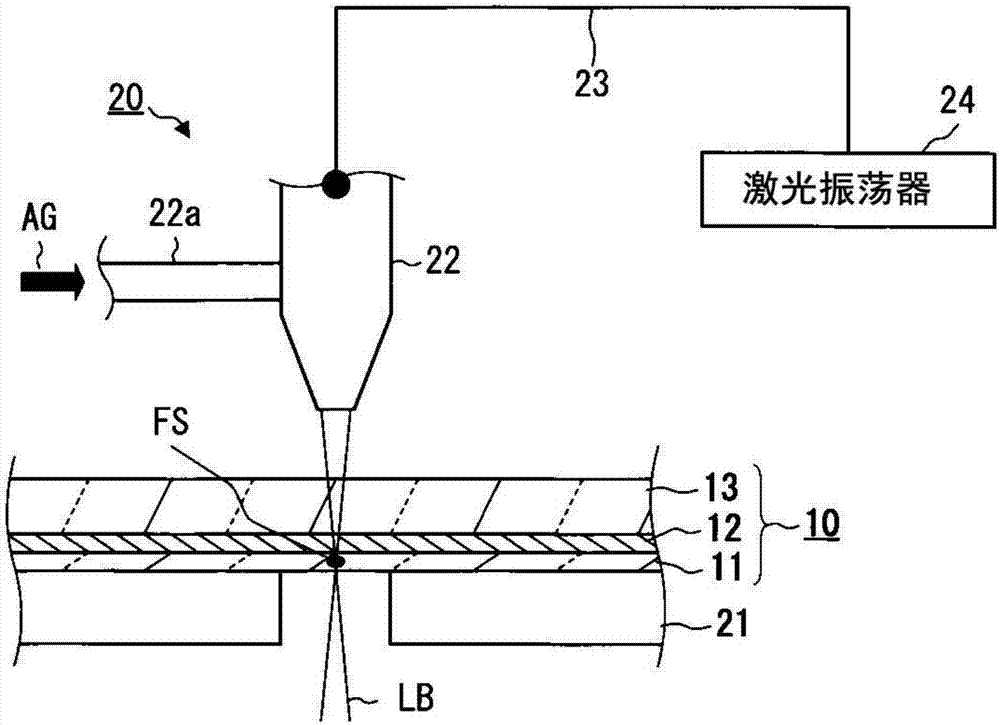

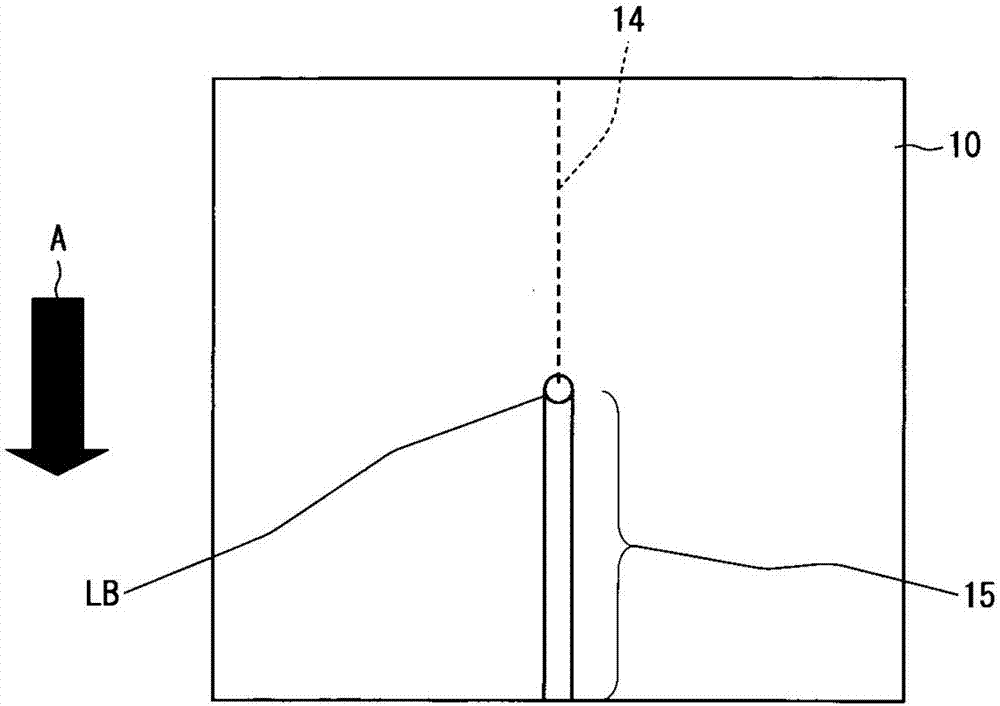

[0211] Laser light LB is vertically incident on the glass laminated body 10 from the support glass 13 side from directly above. At this time, the pulse energy density is set to 14.1J / mm 2 , Overlap rate is set to 25%. Here, the pulse energy density refers to a value obtained by dividing the pulse average energy of the laser beam LB by the pulse area. The overlapping ratio L is expressed by the following formula 4, and the schematic diagram is as follows Figure 5 shown.

[0212] D0 represents the focusing diameter (mm) of the pulse of the laser beam LB, v represents the cutting speed (mm / s), and f represents the oscillation frequency (Hz) of the laser beam LB. After the pulsed spot SP1 is formed, the next spot SP2 is formed at a position moved away from SP1 by the moving distance v / f [mm].

[0213] L=(D0-v / f) / D0×100···Formula (4)

[0214] Tables 1 and 2 show exampl...

Embodiment 2~4

[0232] In Examples 2 to 4, the pulse energy density and overlap ratio in Example 1 were changed to the values shown in the table, and the other conditions were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com