Method for inducing periodic structure on surface of optical glass by picosecond laser

A periodic structure and optical glass technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem that it is difficult to form uniform LIPSS on the surface of optical glass, and achieve the goal of reducing surface reflectivity and increasing transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

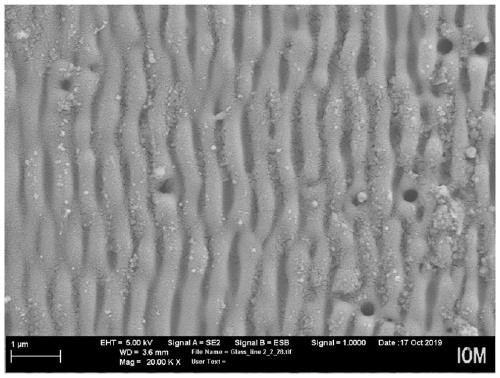

[0026] This embodiment describes the technical scheme of the present invention in detail by taking the etching process of the LIPSS on the surface of K9 glass as an example, as figure 1 shown.

[0027] (1) A K9 glass substrate with a diameter of 2.5cm, a thickness of 2mm, and double-sided polishing is used.

[0028] (2) A linearly polarized laser with a wavelength of 532nm and a pulse width of 8ps is selected as the light source. The laser is incident from the surface of K9 glass and focused on the surface of the material.

[0029] (3) Use a 150mm focal length lens to focus the laser beam so that the laser focus is located on the K9 glass surface, and the spot diameter is 32.5 μm.

[0030] (4) The energy density range of the spot is 4.72J / cm 2 to 13.27J / cm 2 .

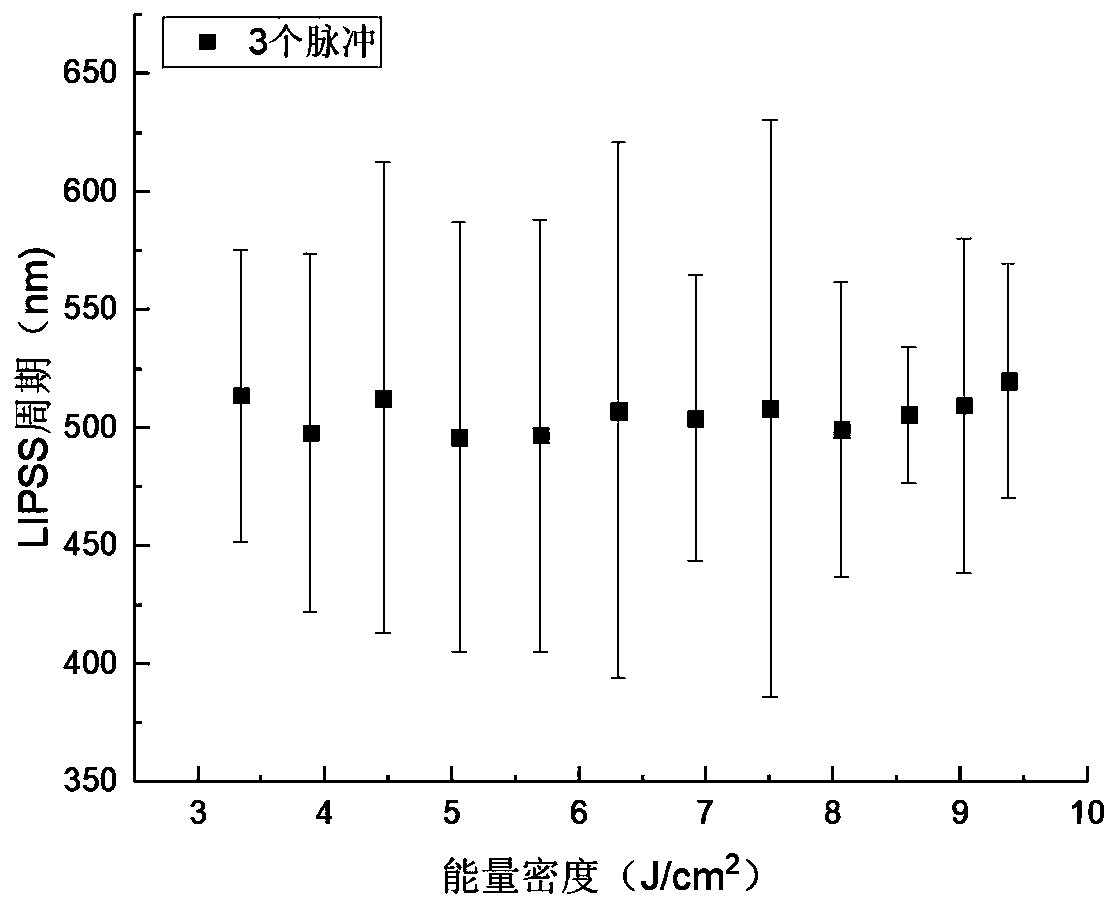

[0031] (5) Through the action of 1-20 pulsed lasers, LIPSS with a period between 480nm and 510nm will be generated on the surface (incident surface) of K9 glass. As the number of pulses increases, the depth of LIPS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com