Surface protection layer for improving stability of perovskite nanosheet laser and preparation method thereof

A technology of nanosheets and protective layers, which is applied in the field of perovskite nanosheet lasers, can solve the problems of losing the thermal stability of perovskite nanosheet lasers, and achieve the effects of improving air stability, stability, and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

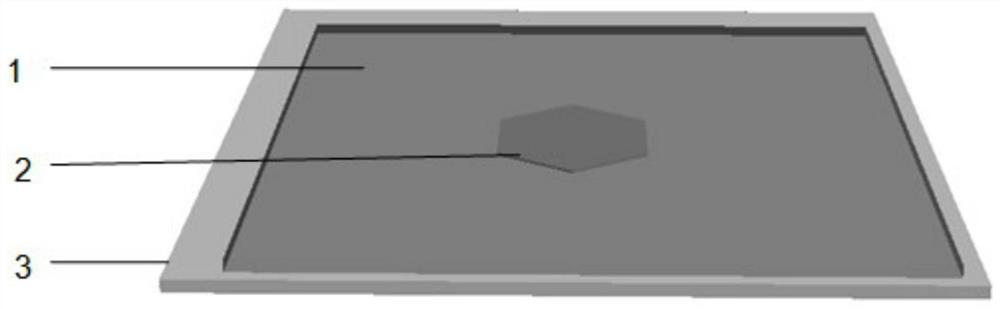

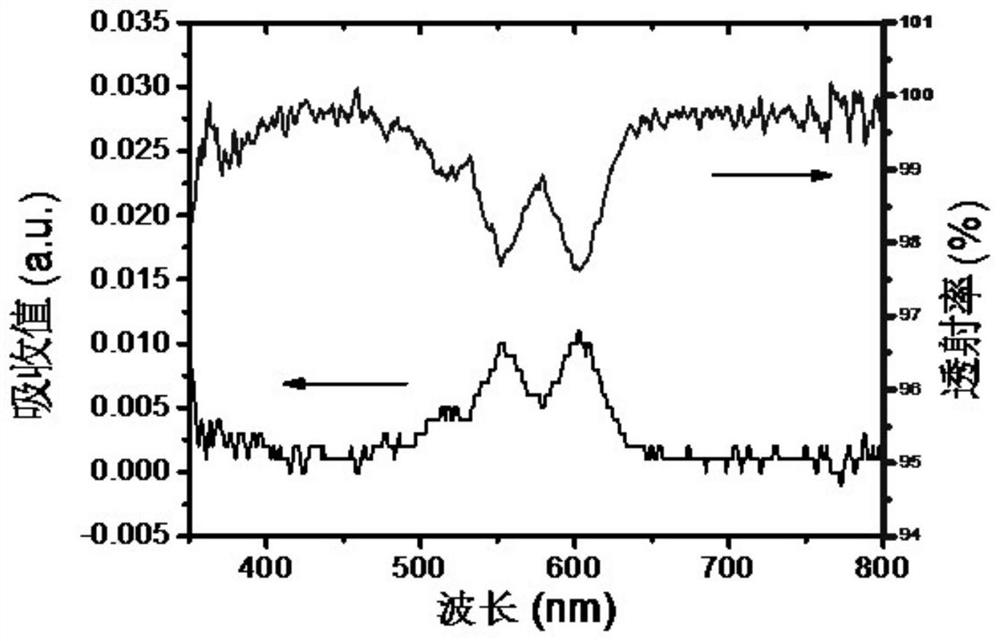

[0022] 1. Preparation of perovskite nanosheets Atomically smooth PbI was fabricated on a mica sheet substrate by physical vapor deposition 2 Template, the lead iodide template is placed above the quartz tube in the tube furnace, methylammonium iodide (MAI) is placed near the template below the quartz tube, and the lead iodide and MAI are reacted to form regular and Unwrinkled facets, atomically smooth perovskite nanosheets with an average surface roughness of less than 2 nm (Adv. Funct. Mater. 2018, 1805553). It has a low density of surface defect states, which is conducive to the formation of low-threshold, high-quality factor lasers, and has good optical stability under continuous pump output conditions. Similarly, with PbBr 2 , PbCl 2 The perovskite nanosheets prepared as templates can be applied to perovskite nanosheet lasers as optical resonators and gain media at the same time.

[0023] 2. Preparation of protective layer

[0024] Spin-coat the protective layer on it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com