Protective layer for semiconductor thin film transistor and its realization and application method

A thin-film transistor and semiconductor technology, applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as unstable illumination, achieve stable and reliable illumination stability, good shading effect, and suppress the change of defect states. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

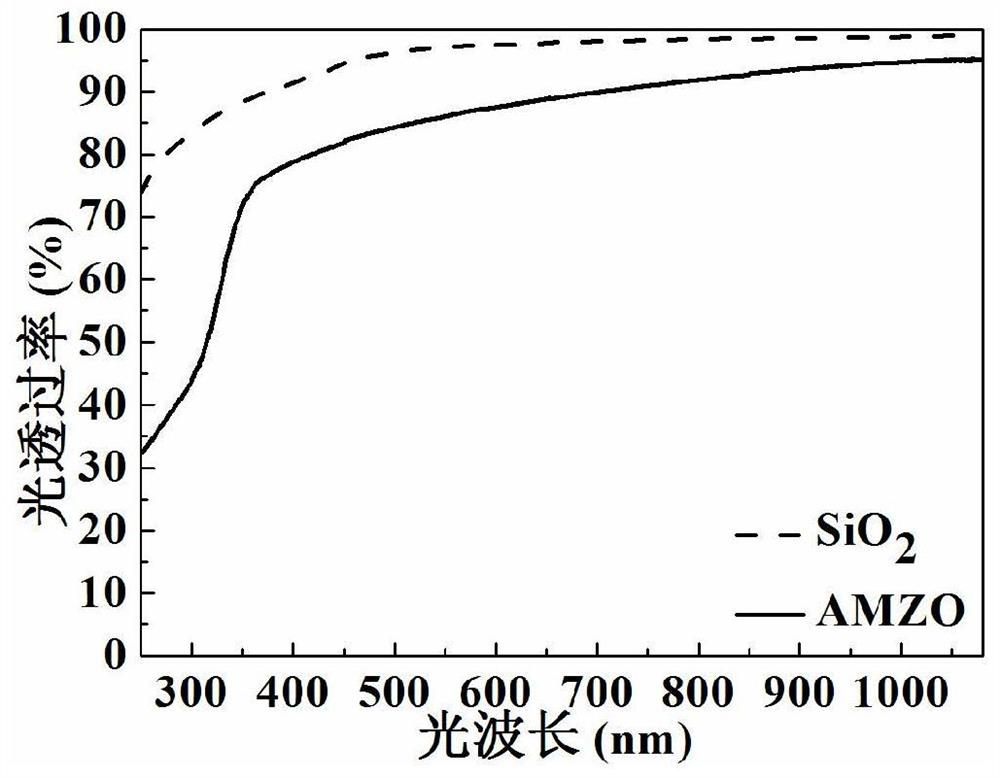

[0034] Such as figure 1 As shown, it is a kind of Al-Mn-Zn oxide thin film with better shielding short-wavelength UV light and traditional SiO 2 Schematic diagram of the comparison of light transmittance of the film, in which the aluminum manganese zinc oxide film is Al 2 o 3 , MnO and ZnO three dopants are mixed and ground, pressed into a target, sintered to obtain an Al-Mn-Zn oxide target, and then sputtered by a magnetron sputtering device.

[0035] The three components described (Al 2 o 3 , MnO and ZnO), the doping amount of each component ranges from 3% to 90%wt%. In this embodiment, the target ratio used is Al 2 o 3 :MnO:ZnO=6:5:89wt%.

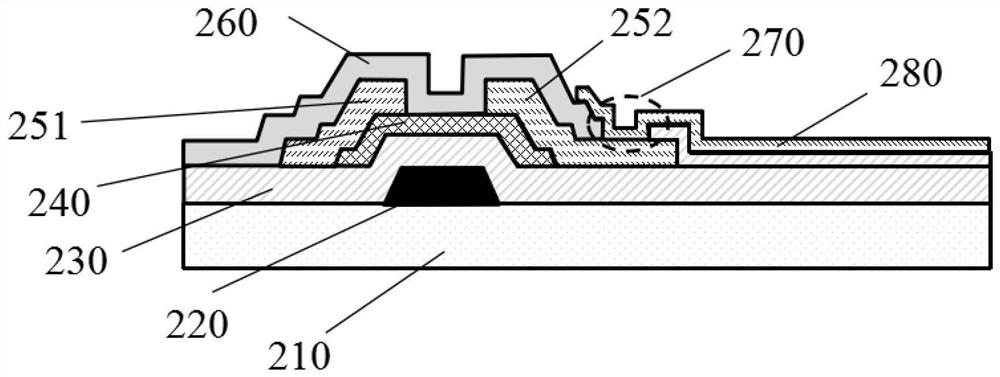

[0036] Such as figure 2 As shown, it is a nitrogen-doped amorphous oxide semiconductor thin film transistor using a single-layer aluminum-manganese-zinc oxide thin film as a protective layer in this embodiment, including: a gate electrode layer 220 sequentially formed on a glass substrate 210 , a gate insulating layer 230 , a ni...

Embodiment 2

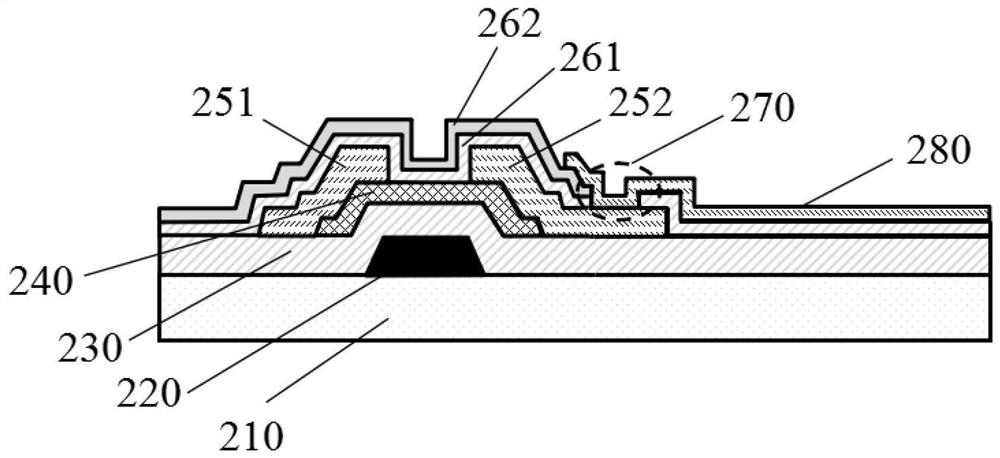

[0043] Such as image 3 As shown, it is a kind of double-layer Al-Mn-Zn oxide / SiO 2 A nitrogen-doped amorphous oxide semiconductor thin film transistor with a thin film as a protective layer. Compared with Embodiment 1, the protective layer in this embodiment includes: a first protective layer 261 and a second protective layer 262, wherein: the first protective layer 261 It is located on the active layer 240 , the drain electrode layer 251 and the source electrode layer 252 and is located under the second protection layer 262 .

[0044] The first protective layer 261 is SiO 2 The thin film is prepared by magnetron sputtering or PECVD equipment, and its thickness is 50nm;

[0045] The second protection layer 262 is an Al-Mn-Zn oxide thin film prepared by magnetron sputtering with a thickness of 50 nm.

[0046] Such as Figure 5 As shown, it is a schematic flow chart of the preparation process of the nitrogen-doped amorphous oxide semiconductor thin film transistor based on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com