Multi-functional optic sheet

An optical sheet, multi-functional technology, used in optics, optical components, nonlinear optics, etc., can solve the problem of lower than expected increase in brightness, and achieve the effect of improving brightness, preventing damage, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

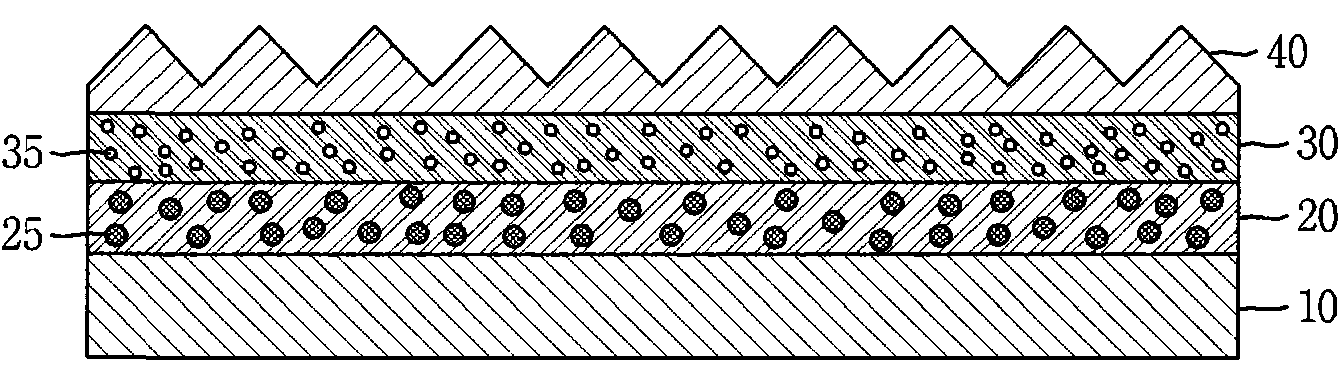

[0061] 100 parts by weight of acrylic resin (52-666 available from Aekyung Chemical Co.) was diluted with 30 parts by weight of methyl ethyl ketone and 80 parts by weight of toluene to prepare an adhesive resin with a refractive index of 1.49. Thereafter, the amount of this binder resin was used as a benchmark, adding 150 parts by weight, an average diameter of 20 μm and a refractive index of 1.49 spherical polymethyl methacrylate particles (MH20F sold by Kolon Company), and then performing a single step with a grinder. Monodisperse treatment in layer form, followed by application of the dispersion thus obtained to a thickness of 188 μm using a gravure coater as a substrate layer of an ultra-transparent polyethylene terephthalate film (FHSS available from Kolon Corporation) ), and then cured at 120° C. for 60 seconds to form a light diffusion layer (refractive index 1.49) with a dry thickness of 25 μm.

[0062] In addition, an air layer was formed on one side of this cured lig...

Embodiment 2

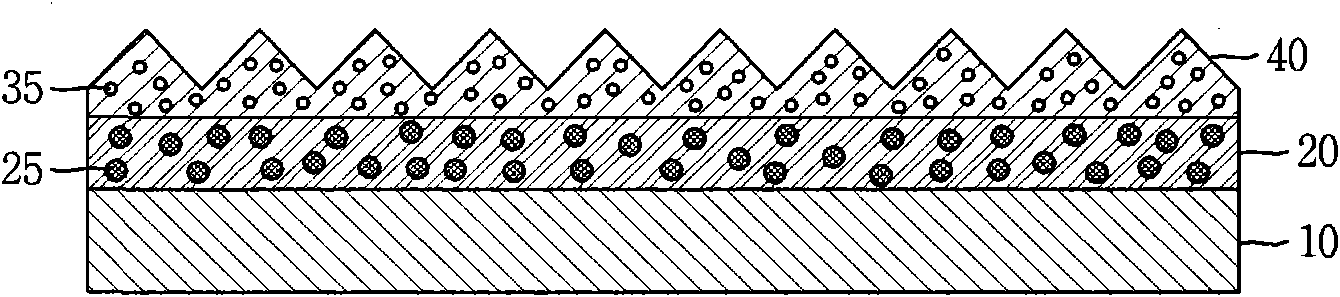

[0065] 100 parts by weight of acrylic resin (52-666 available from Aekyung Chemical Co.) was diluted with 30 parts by weight of methyl ethyl ketone and 80 parts by weight of toluene to prepare an adhesive resin with a refractive index of 1.49. Thereafter, the amount of this binder resin was used as a benchmark, adding 150 parts by weight, an average diameter of 20 μm and a refractive index of 1.49 spherical polymethyl methacrylate particles (MH20F sold by Kolon Company), and then performing a single step with a grinder. Monodisperse treatment in layer form, followed by application of the dispersion thus obtained to a thickness of 188 μm using a gravure coater as a substrate layer of an ultra-transparent polyethylene terephthalate film (FHSS available from Kolon Corporation) ), and then cured at 120° C. for 60 seconds to form a light diffusion layer (refractive index 1.49) with a dry thickness of 25 μm.

[0066]Further, a mixture of 5 parts by weight of isobutane particles and ...

Embodiment 3

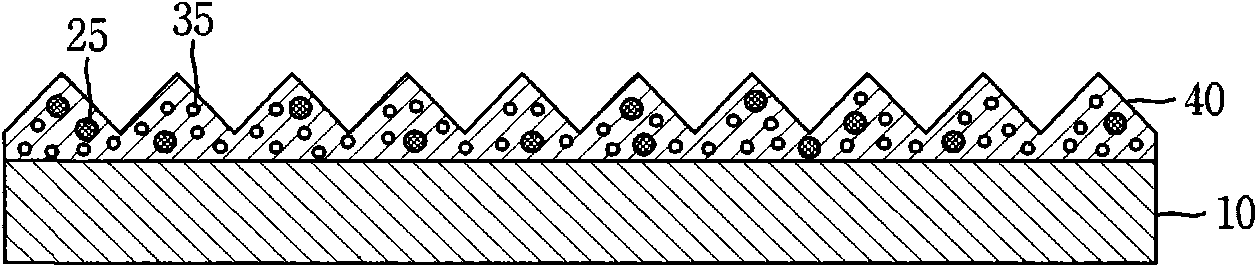

[0068] With 100 parts by weight of the photosensitive resin composition as the criterion, the content is 5 parts by weight of polymethyl methacrylate particles (MH20F sold by Kolon Company), 5 parts by weight of isobutane particles and the photosensitive resin combination The mixture of materials is applied on one side of an ultra-transparent polyethylene terephthalate film (FHSS available from Kolon Company) as a substrate layer with a thickness of 188 μm, wherein the photosensitive resin composition is made of 60 Parts by weight of urethane acrylate, 20 parts by weight of 2-phenylethyl methacrylate, 10 parts by weight of benzyl methacrylate, 5 parts by weight of isobutyl methacrylate, 3 parts by weight of acrylate-1,6- Hexylene glycol ester and 2 parts by weight of BAPO-based photoinitiator. Thereafter, this photosensitive resin composition applied on the substrate layer is coated on the upper surface of the frame of the prism-shaped cylinder, and then the outer surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com