Aqueous marking ink composition

A composition and marking technology, applied in ink, optics, instruments, etc., can solve problems such as insufficient shielding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15 and comparative example 1-11

[0137] An aqueous marking ink composition (total amount: 100%) was prepared by an ordinary method based on the formulations shown in Table 1 and Table 2 below.

[0138] Measured at 25°C in 3.83 to 383sec by the following measurement method -1 Each viscosity of each aqueous marking ink composition obtained under each shear rate of .

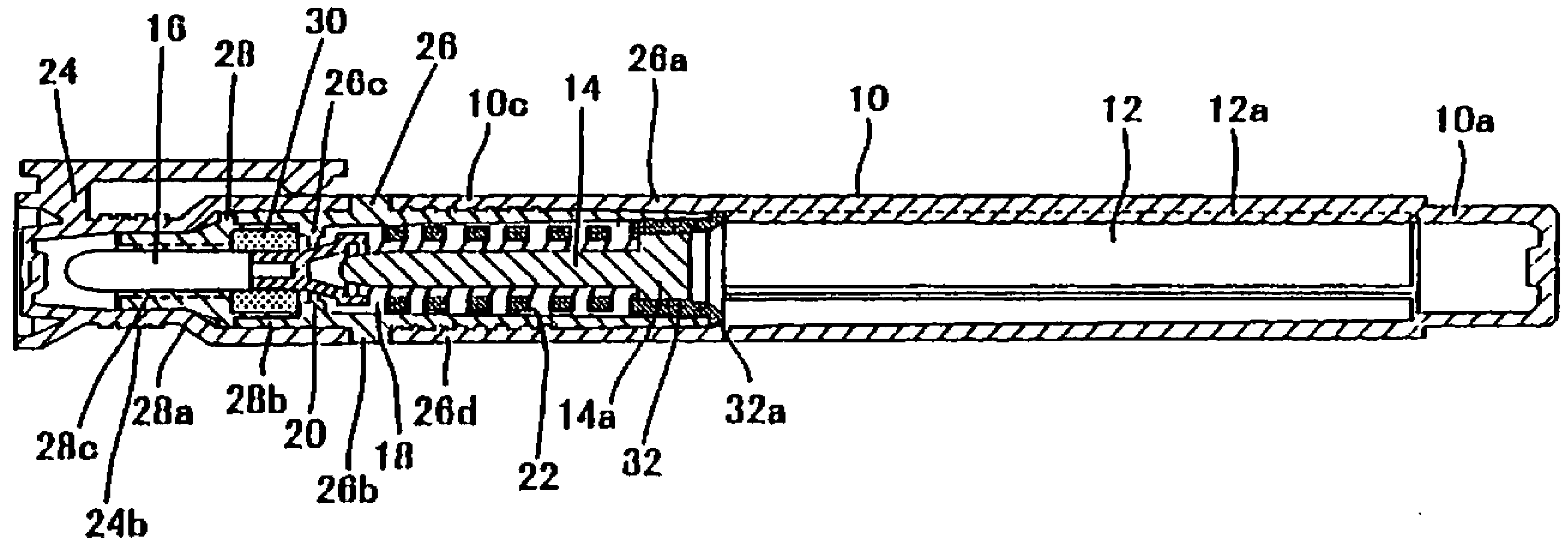

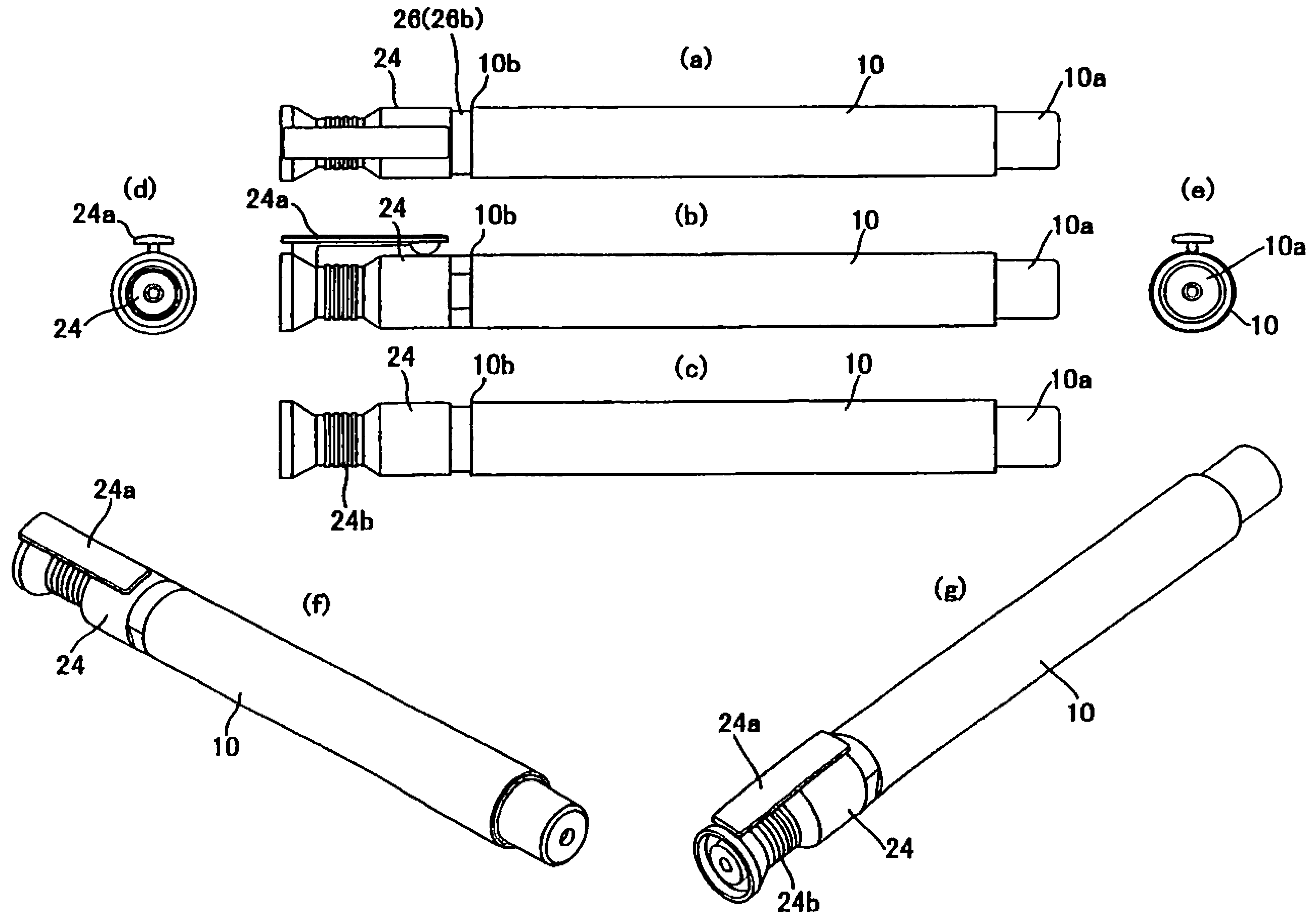

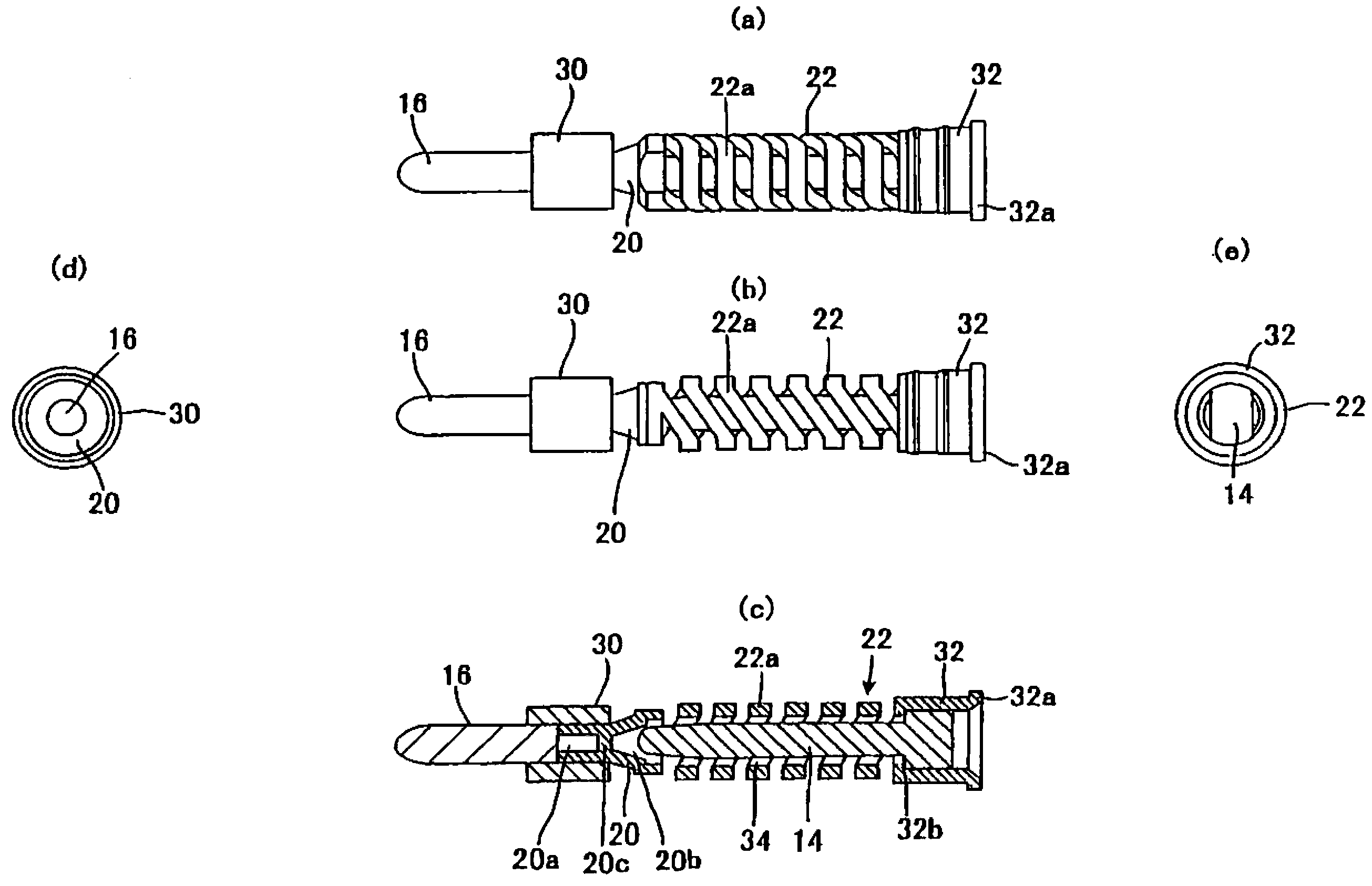

[0139] In addition, each obtained aqueous marking ink composition was used and filled into a marking pen having the following configuration to evaluate hiding property (non-absorbing black surface), fixation property (metal surface), line drawing state (metal surface contaminated with oil) , writing performance (flow out), restirrability (bead migration frequency), writing performance during repeated writing (pen tip up repetition) and downward storage performance (pen supply clogging).

[0140] The results are shown in Tables 1 and 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com