Heterojunction solar cell and preparation method thereof

A solar cell and heterojunction technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problem of affecting the short-circuit current and fill factor of heterojunction solar cells, increasing the production cost of heterojunction solar cells, and affecting the heterojunction Improve the efficiency of solar cells and other issues to achieve the effect of improving short-circuit current and fill factor, improving passivation effect, and avoiding high series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

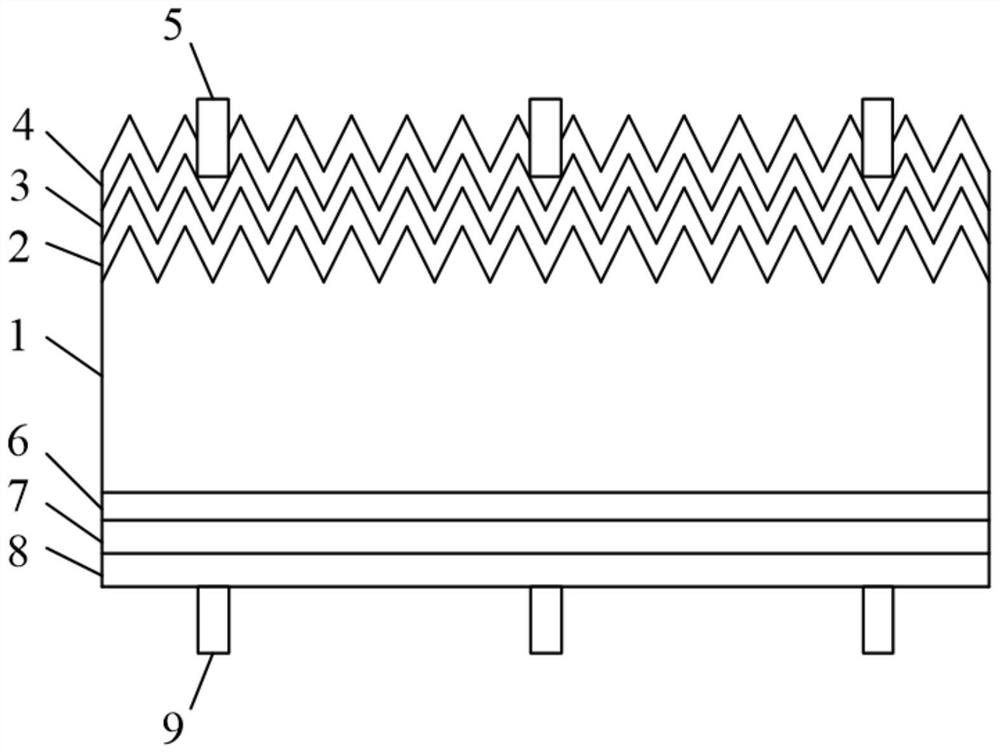

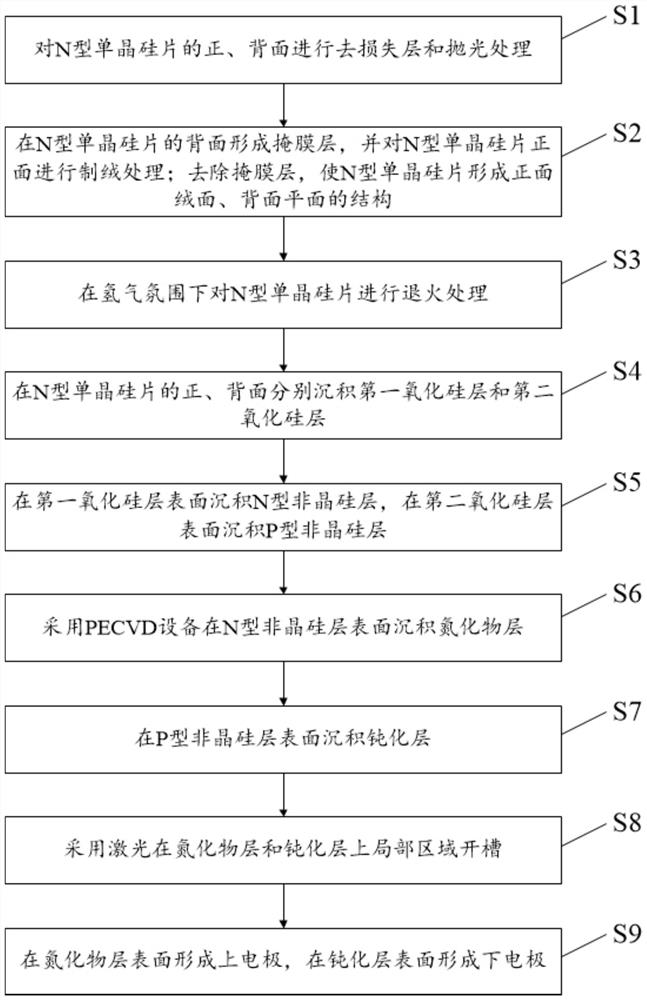

[0046] Correspondingly, see figure 2 As shown, the present invention also provides a method for preparing a heterojunction solar cell, comprising:

[0047] S1, removing the loss layer and polishing the front and back of the N-type single crystal silicon wafer;

[0048] Specifically, select an N-type single crystal silicon wafer with a thickness of 100-180 μm; clean the surface of the N-type single crystal silicon wafer to remove organic pollution and metal ions; Carry out sacrificial layer removal and polishing;

[0049] S2. Form a mask layer on the back side of the N-type single crystal silicon wafer, and perform texturing treatment on the front side of the N-type single crystal silicon wafer; remove the mask layer, so that the N-type single crystal silicon wafer forms a textured front surface and a flat back surface structure;

[0050] The structure of the back plane is formed by back polishing;

[0051] Specifically, a mask layer is formed on the back side of the N-typ...

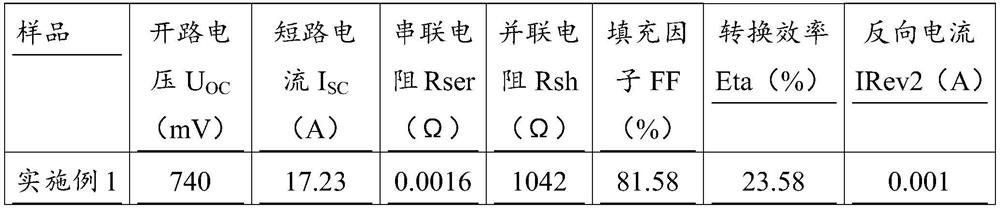

Embodiment 1

[0075] S1, removing the loss layer and polishing the front and back of the N-type single crystal silicon wafer;

[0076] S2. Form a mask layer on the back side of the N-type single crystal silicon wafer, and perform texturing treatment on the front side of the N-type single crystal silicon wafer; remove the mask layer, so that the N-type single crystal silicon wafer forms a textured front surface and a flat back surface structure;

[0077] S3, performing annealing treatment on the N-type single crystal silicon wafer in a hydrogen atmosphere;

[0078] S4. Depositing a first silicon oxide layer and a second silicon oxide layer on the front and back sides of the N-type single crystal silicon wafer respectively, the thicknesses of the first silicon oxide layer and the second silicon oxide layer are both 2 nm;

[0079] S5. Depositing an N-type amorphous silicon layer on the surface of the first silicon oxide layer, depositing a P-type amorphous silicon layer on the surface of the ...

Embodiment 2

[0085] A method for preparing a heterojunction solar cell, comprising:

[0086] S1, removing the loss layer and polishing the front and back of the N-type single crystal silicon wafer;

[0087] S2. Form a mask layer on the back side of the N-type single crystal silicon wafer, and perform texturing treatment on the front side of the N-type single crystal silicon wafer; remove the mask layer, so that the N-type single crystal silicon wafer forms a textured front surface and a flat back surface structure;

[0088] S3, performing annealing treatment on the N-type single crystal silicon wafer in a hydrogen atmosphere;

[0089] S4. Depositing a first silicon oxide layer and a second silicon oxide layer respectively on the front and back of the N-type single crystal silicon wafer, the thickness of the first silicon oxide layer and the second silicon oxide layer are both 1 nm;

[0090] S5. Depositing an N-type amorphous silicon layer on the surface of the first silicon oxide layer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com