High-adhesion low-warpage crystalline silicon cell back side aluminum slurry

A high-adhesion, crystalline silicon battery technology, applied in the direction of conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve the problem of reducing the thermal expansion coefficient of Al-Si, affecting the mechanical and electrical properties of batteries, and reducing aluminum The interaction between slurry particles and other issues can be achieved to reduce the thermal expansion coefficient, ensure the passivation effect of the back field, and ensure the effect of the back field adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments.

[0027] Preparation method: Prepare aluminum powder, glass powder and additives respectively, and the organic carrier is composed of terpineol, butyl carbitol, butyl carbitol acetate, alcohol ester twelve, DBE, ethyl cellulose, resin One or more substances are mixed and then dissolved at 100-200°C and stirred uniformly, and then the raw material components are mixed to obtain aluminum paste.

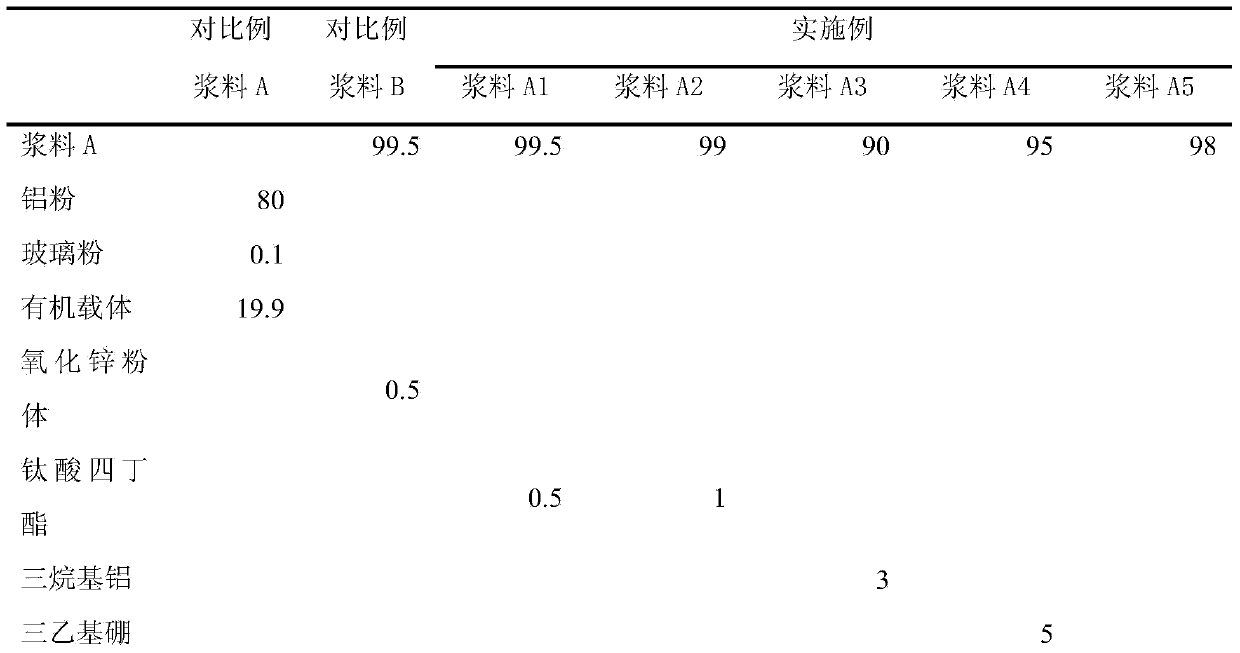

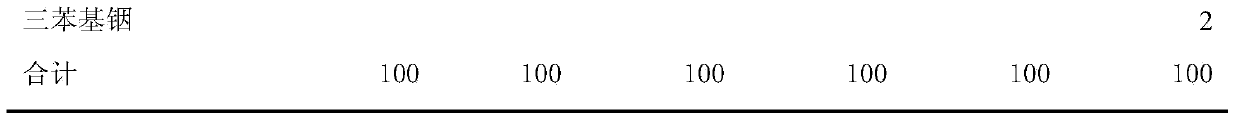

[0028] According to the above preparation method, as shown in Table 1, slurry A is a control group, B is a comparative example adding general oxide powder as an additive, and slurries A1 to A5 are five specific implementation methods of the aluminum slurry of the present invention.

[0029] Table 1 Proportion of aluminum paste (w%)

[0030]

[0031]

[0032] Among them, the glass powder used in all aluminum pastes is Bi2O3-SiO2-ZnO lead-free glass powder, the model is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com