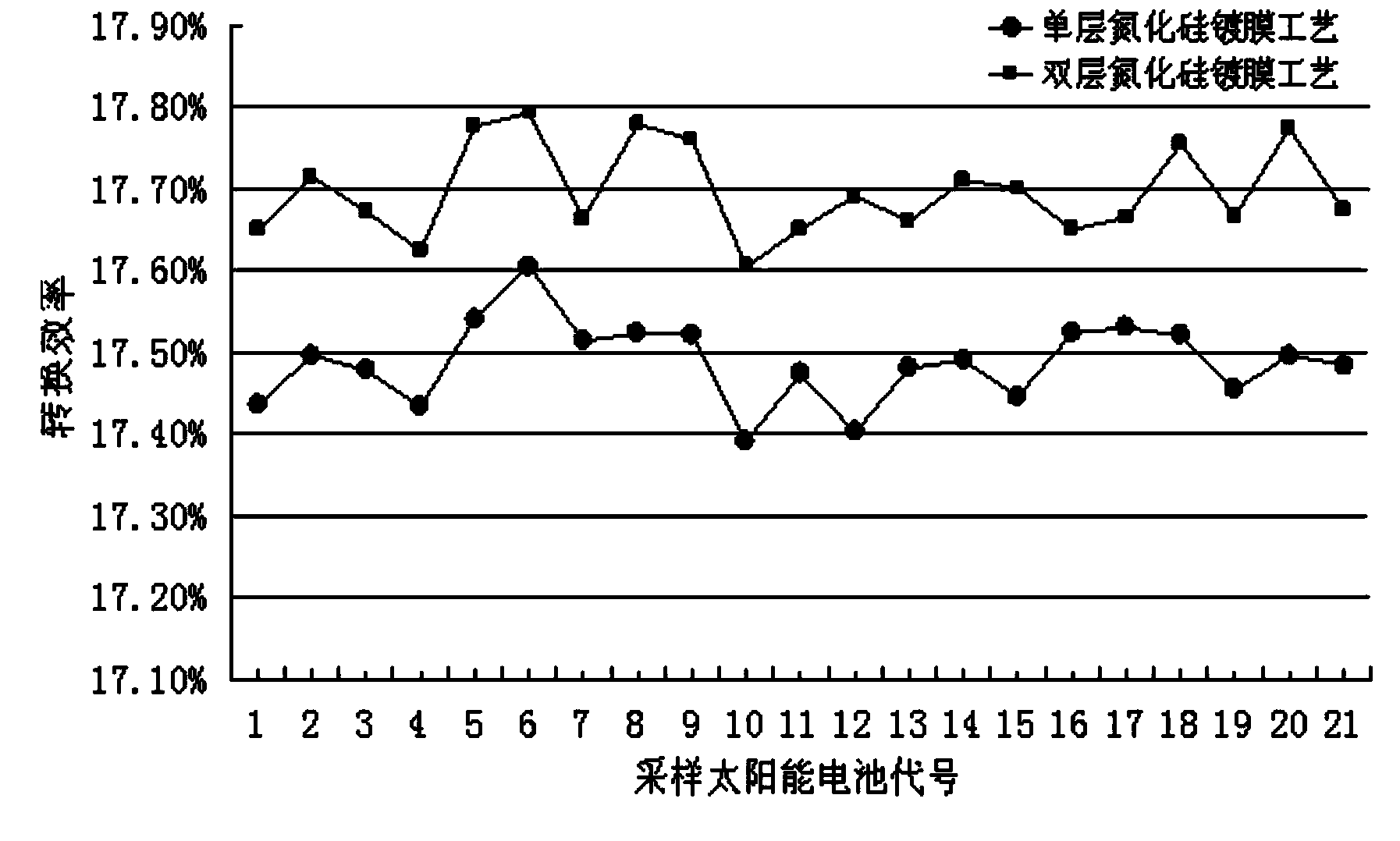

Coating film process for metallurgical grade monocrystalline silicon solar cell double-layer anti-reflection film

A solar cell and monocrystalline silicon technology, which is applied in metal material coating process, coating, circuit, etc., can solve the problem of poor passivation effect of metallurgical-grade monocrystalline silicon wafers, low conversion efficiency of cells, and low conversion efficiency, etc. problem, to achieve good passivation effect, broaden the market, and narrow the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The double-layer silicon nitride anti-reflection coating process for metallurgical-grade monocrystalline silicon solar cells of the present invention is mainly applied to tubular PECVD coating machines, and its specific implementation is shown in the following steps:

[0022] (1) Vacuuming: Vacuumize the reaction chamber of the tubular PECVD coating machine until the pressure value drops to 30mTorr;

[0023] (2) Ammonia and silane enter: the time is 15s, the flow rate of ammonia gas is controlled to 6400sccm, the flow rate of silane to 1400sccm, and the final pressure value of the reaction chamber reaches 1600mTorr;

[0024] (3) The first coating step: the coating time is 110s, the coating temperature is 450°C, the RF power is 6300W, and the pulse switching time ratio is 4:45;

[0025] (4) Changing the flow rate of ammonia and silane: first vacuumize the reaction chamber after the first coating for 150s, and reduce the pressure to 30mTorr, then inject ammonia and silane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com