Manufacturing method of silicon-based solar cell P-type surface tunneling oxidation and passivation contact

A solar cell, tunneling oxidation technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of limited passivation effect on the P-type surface of the cell, damage to the passivation layer, and affecting the electrical performance of the cell, and achieve excellent Passivation effect, increase open circuit voltage, and reduce the effect of interface state density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

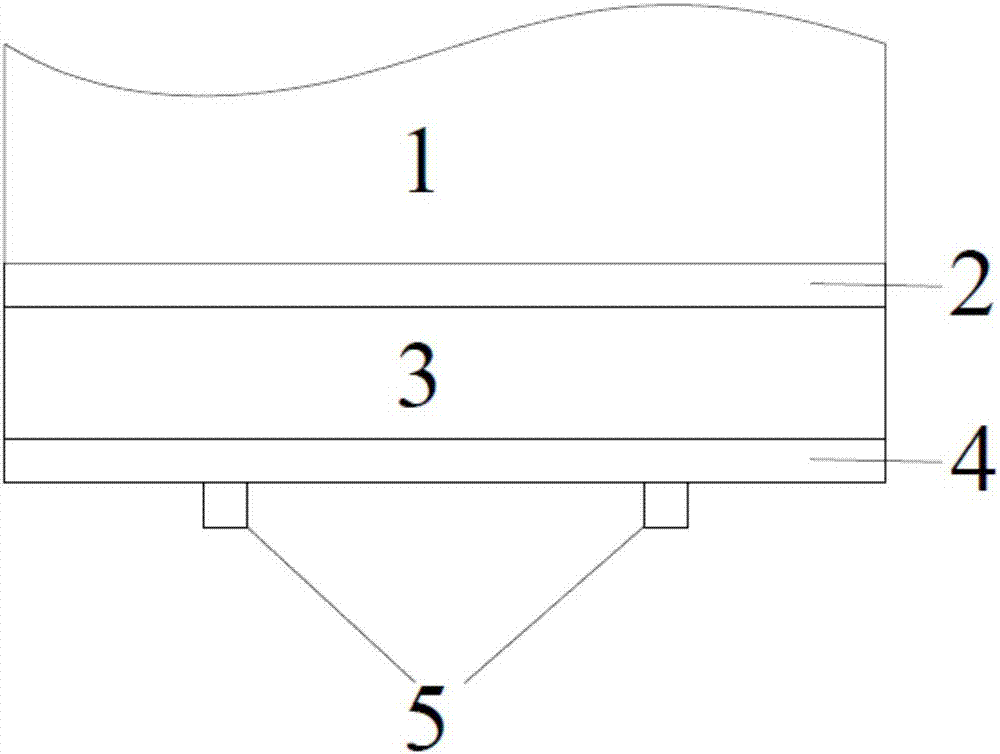

Image

Examples

Embodiment 1

[0029] A method for fabricating a P-type surface tunneling oxidation passivation contact of a silicon-based solar cell, specifically adopting the following steps:

[0030] (1) After etching, texturizing, polishing, diffusion and ion implantation on the single crystal silicon wafer, use HF to clean the P-type surface of the single crystal silicon wafer that needs tunneling oxidation passivation contact, Remove SiO2, BSG, PSG and other oxide layers on the surface of silicon wafers;

[0031] (2) Oxidize the surface of the silicon wafer to form an ultra-thin tunnel oxide layer with a thickness of 1 nm. The oxide layer growth method uses concentrated nitric acid to oxidize the surface of the silicon wafer, and the thickness of the oxide layer is controlled by the concentration, temperature and oxidation time of concentrated nitric acid. The concentration of nitric acid is 69%, the temperature is 25°C, and the time is 10 minutes;

[0032] (3) Deposit a thin silicon layer above the ...

Embodiment 2

[0038] A method for fabricating a P-type surface tunneling oxidation passivation contact of a silicon-based solar cell, specifically adopting the following steps:

[0039] (1) After etching, texturing, polishing, diffusion, and ion implantation on the single crystal silicon wafer, the P Clean the surface of the silicon wafer to remove SiO2, BSG, PSG and other oxide layers on the surface of the silicon wafer;

[0040] (2) Oxidize the surface of the silicon wafer to form an ultra-thin tunnel oxide layer with a thickness of 2nm. Ozone is used to oxidize the surface of the silicon wafer to grow the oxide layer, and the thickness of the oxide layer is controlled by the concentration, temperature and oxidation time of the ozone. The ozone concentration is 50ppm, the temperature is 100°C, and the time is 10 minutes;

[0041] (3) A thin layer of silicon is deposited on the ultra-thin tunneling oxide layer by chemical vapor deposition, and a low-pressure chemical vapor deposition method...

Embodiment 3

[0046] A method for fabricating a P-type surface tunneling oxidation passivation contact of a silicon-based solar cell, specifically adopting the following steps:

[0047] (1) After etching, texturizing, polishing, diffusion and ion implantation on the single crystal silicon wafer, use HF to clean the P-type surface of the single crystal silicon wafer that needs tunneling oxidation passivation contact, Remove SiO2, BSG, PSG and other oxide layers on the surface of silicon wafers;

[0048] (2) Oxidize the surface of the silicon wafer to form an ultra-thin tunnel oxide layer with a thickness of 1.5nm. The way of oxide layer growth is thermal oxidation, and the thickness of the oxide layer is controlled by the oxidation temperature and time. The temperature is 600°C and the time is 20 minutes;

[0049] (3) A thin layer of silicon is deposited on the ultra-thin tunneling oxide layer by chemical vapor deposition, and a low-pressure chemical vapor deposition method is used, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com