Method for producing heavy metal passivators for farmland soil and application of heavy metal passivators

A heavy metal passivator and production method technology, applied in chemical instruments and methods, applications, soil conditioning materials, etc., can solve the problems of secondary pollution, high cost, incomplete clarity, etc., to reduce the residual of harmful substances, fast speed , the effect of simple and easy technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

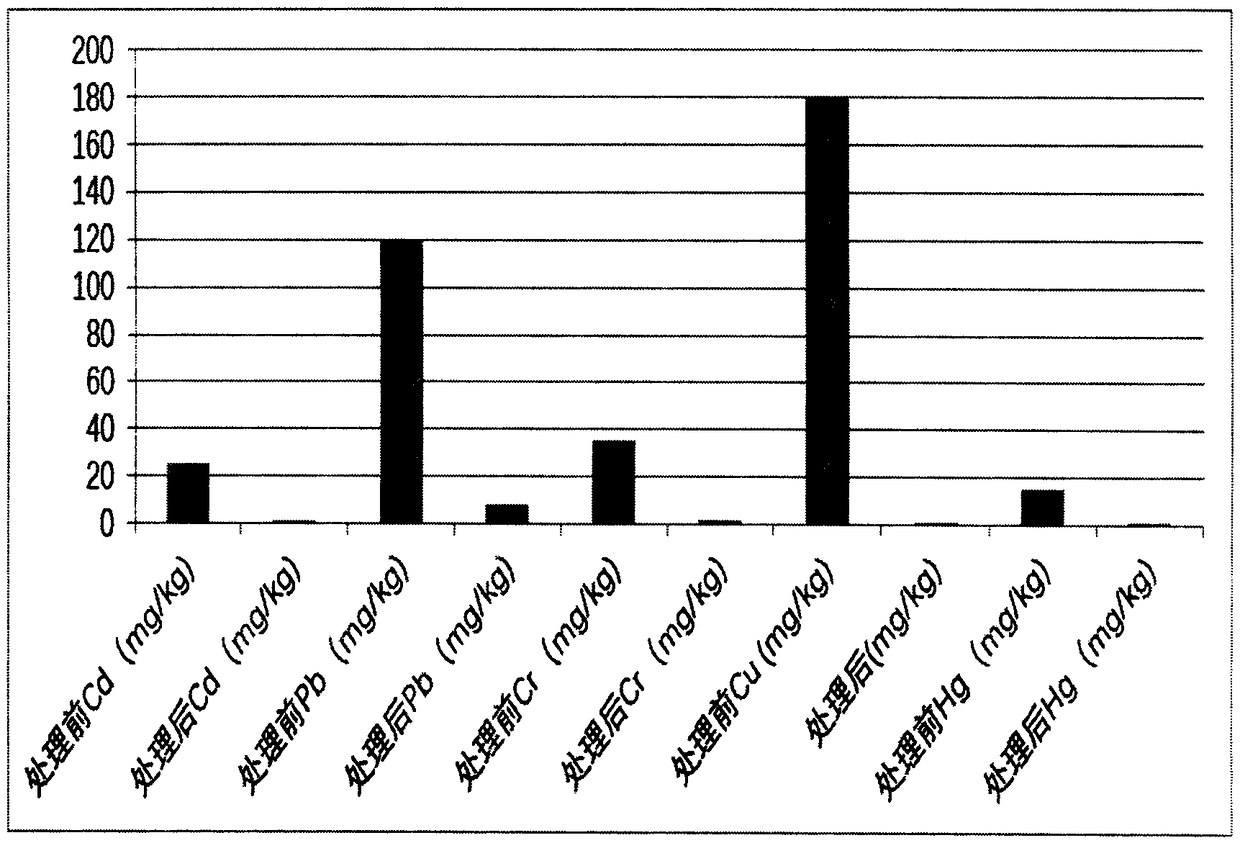

Examples

Embodiment 1

[0028] 1. Add 500 grams of calcium polysulfide, 500-2500 potassium sulfide, 500-2500 grams of dipotassium hydrogen phosphate, 500 grams of sodium lignosulfonate, 1000 grams of potassium humate, 500 grams of bentonite in a 10-liter suspension, 500 grams of quicklime, stir slowly, add 500 grams of sodium silicate and 500 grams of EDTA after mixing, slowly stir, transfer to a ball mill for crushing, and make a powder mixture with a particle size of about 300 mesh.

[0029] 2. Add 800 grams of the product treated in the above 1 into a container containing 10 kilograms of soil, let the mixture fully contact with the heavy metals in the soil, and fully react. Before adding the above mixture, add 1000 grams to the soil containing heavy metals Milliliters of distilled water, fully moisten the soil, and make the soil particles and voids evenly distributed, without large holes and soil clods.

[0030] 3. Stir the soil and the added passivator mixture after the above 1 treatment, keep st...

Embodiment 2

[0032]1. Add 2,000 grams of calcium polysulfide, 1,500 grams of potassium sulfide, 1,500 grams of dipotassium hydrogen phosphate, 1,000 grams of sodium lignosulfonate, 1,500 grams of potassium humate, 1,500 grams of bentonite, and 1,000 grams of quicklime in a 10-liter suspension. Stir slowly, add 1,000 grams of sodium silicate and 800 grams of EDTA after everything is mixed, stir slowly, transfer to a ball mill for crushing, and make a powder mixture with a particle size of about 300 mesh.

[0033] 2. Add 500 grams of the product treated in the above 1 into a container containing 10 kilograms of soil, let the mixture fully contact with the heavy metals in the soil, and fully react. Before adding the above mixture, add 2000 grams to the soil containing heavy metals Milliliters of distilled water, fully moisten the soil, and make the soil particles and voids evenly distributed, without large holes and soil clods.

[0034] 3. Stir the soil and the added passivator mixture after ...

Embodiment 3

[0036] 1. Add 5,000 grams of calcium polysulfide, 2,500 grams of potassium sulfide, 2,500 grams of dipotassium hydrogen phosphate, 1,500 grams of sodium lignosulfonate, 2,000 grams of potassium humate, 2,500 grams of bentonite, and 1,500 grams of quicklime in a 10-liter suspension , Stir slowly, after everything is mixed, add 1500 grams of sodium silicate and 1000 grams of EDTA, the total amount is about 20 kg, stir slowly, transfer to a ball mill for crushing, and make a powder mixture with a particle size of about 300 mesh.

[0037] 2. Add 100 grams of the product treated in the above 1 into a container containing 10 kilograms of soil, let the mixture fully contact with the heavy metals in the soil, and fully react. Before adding the above mixture, add 4000 Milliliters of distilled water, fully moisten the soil, and make the soil particles and voids evenly distributed, without large holes and soil clods.

[0038] 3. Stir the soil and the added passivator mixture after the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com